Steel ring deflection distance detection course and instrument construction

A detection process and steel ring technology, applied in the direction of mechanical gap measurement, etc., can solve the problems of inaccurate detection results, affecting the quality of steel rings, and complicated actions, so as to improve the detection effect, improve the economic benefits of enterprises, and ensure the effect of product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

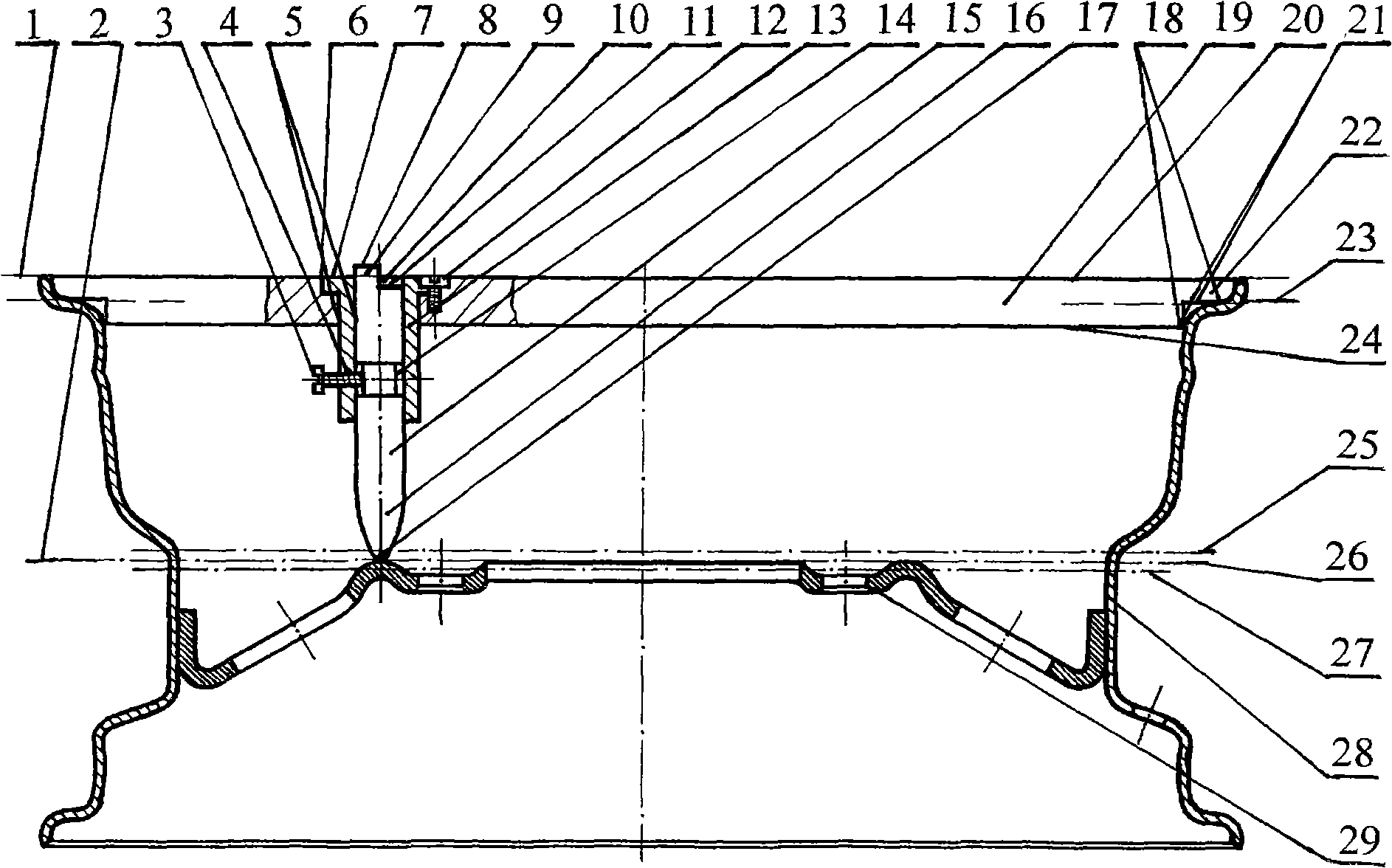

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] The rim offset detection process and the structure of the instrument, as shown in the figure, include the operation process of detecting the rim offset and the structure of the rim offset detection instrument: the structure of the rim offset detection instrument, first, on the spoke installation plane One side of 25 or 26 or 27, from the center plane 2 of the rim to a position that maintains an appropriate distance and is parallel to each other, a reference plane 1 is set, and then the center plane 2 of the rim and the spoke installation plane 25 / 27 or 26 are aligned with each other The distance kept parallel or coincident is determined as the design distance, and the result obtained by subtracting the distance from the center plane 2 of the rim to the reference plane 1 and the distance from the spoke installation plane 25 / 27 or 26 to the referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com