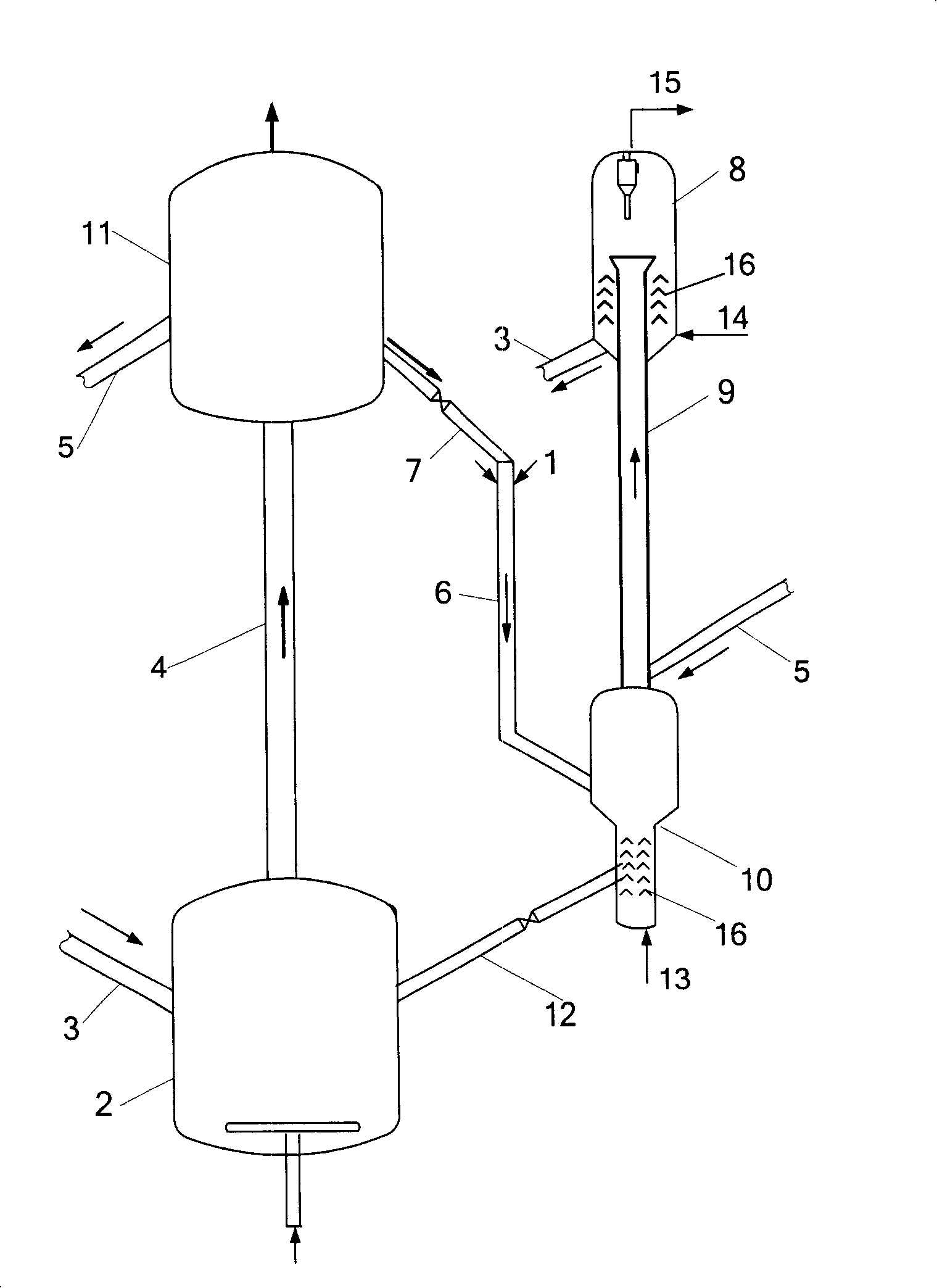

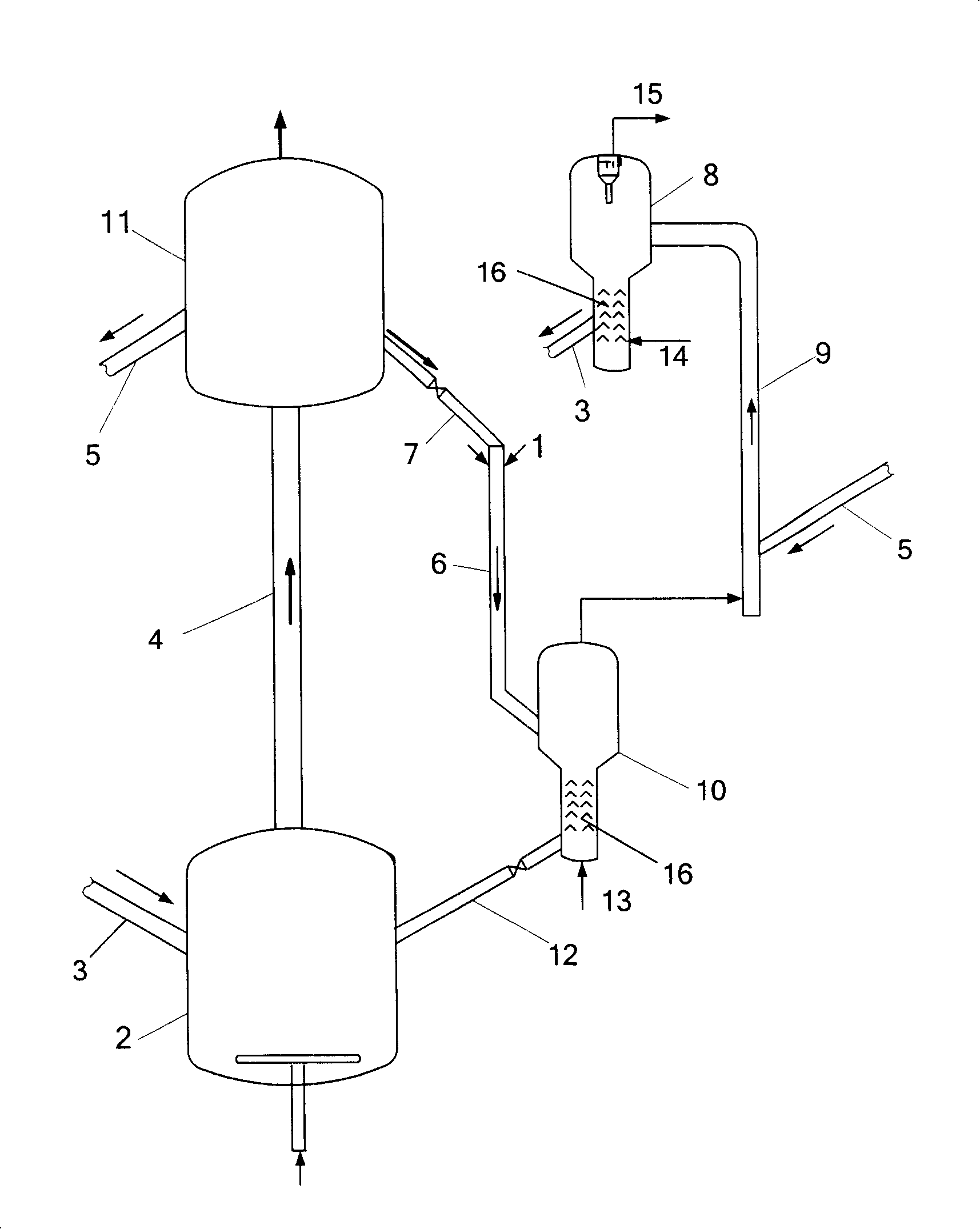

Descending reactor and riser reactor serially connected catalytic cracking method

A technology of reactors connected in series and catalytic cracking units, which is applied in catalytic cracking, cracking, petroleum industry, etc., can solve problems affecting raw material conversion, catalyst activity reduction, thermal cracking reaction, etc., to reduce sulfur content and increase gasoline yield efficiency and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The raw material oil is intermediate base deasphalted oil, the catalyst is a DCC balancer, and the reaction is carried out in a small down-riser reactor with a processing capacity of 2kg / h. The properties of the raw material are shown in Table 1, and the properties of the catalyst are shown in Table 2. Operating conditions And the product distribution is shown in Table 3.

Embodiment 2

[0040] The raw material oil is intermediate base deasphalted oil, and the catalyst is MLC-500 balancer. The reaction is carried out in a small down-riser device with a processing capacity of 2kg / h. The properties of the raw materials are shown in Table 1, the properties of the catalyst are shown in Table 2, and the operating conditions and product distribution are shown in Table 3.

[0041] Table 1

[0042] Raw oil

Intermediate base deasphalted oil

Density (20℃), g / cm 3

0.8976

Elemental composition, weight %

C / H

86.1 / 12.8

S / N

0.56 / 0.15

average molecular weight

620

Distillation range

initial boiling point

245

10%

398

50%

465

90%

546

<350℃ content

7

[0043] Table 2

[0044] project

DCC Balancer

MLC-500 Balancer

Specific surface, m 2 / g

191

187

Pore vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com