System integrating air separation with cool capacity recovery of liquefied natural gas

A technology of liquefied natural gas and cold energy recovery, applied in the direction of liquefaction, refrigeration and liquefaction, cold treatment separation, etc., to achieve great social and economic benefits, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

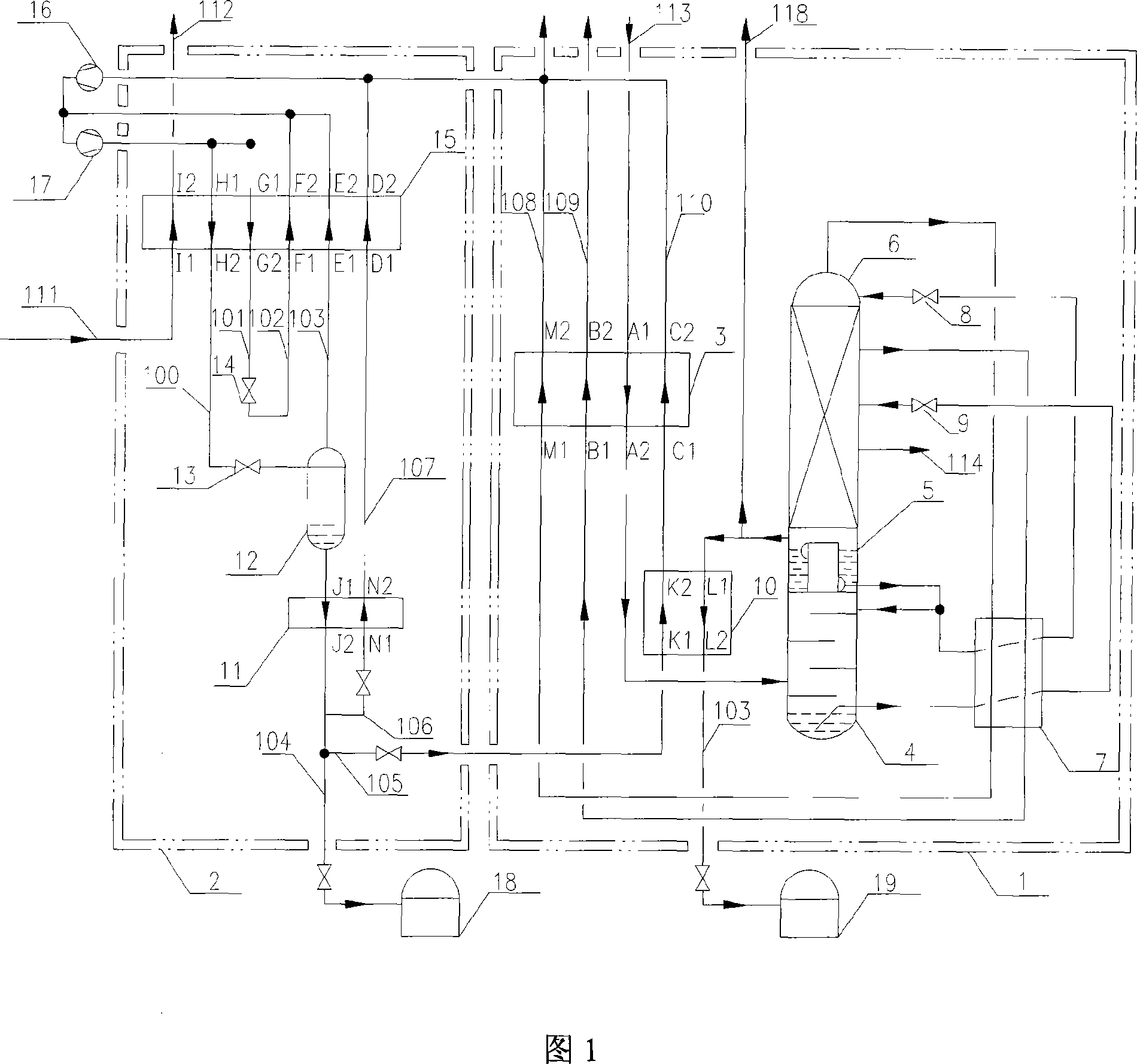

[0027] Embodiment 1: as shown in Figure 1, the feed air 113 that removes carbon dioxide, water, acetylene and other hydrocarbon impurities is sent into the heat exchange channel A1-A2 of the main heat exchanger 3 in the cold box I1, and other heat exchangers The reflux gas in the hot channel is exchanged for heat, cooled to a suitable fractionation temperature, and sent to the bottom of the fractionation lower tower 4 .

[0028] The main heat exchanger 3, fractionation column and liquid oxygen heat exchanger 10 are located inside the independent cold box I1. The fractionation tower is composed of a fractionation lower tower 4, a fractionation upper tower 6 and a main condensing evaporator 5 connected. The cooled raw material air enters the bottom of the lower fractionation tower 4, and the heat and mass transfer process occurs on the multi-layer trays with the reflux liquid flowing down from the top of the lower fractionation tower 4. Oxygen-enriched liquid air with a higher ...

Embodiment 2

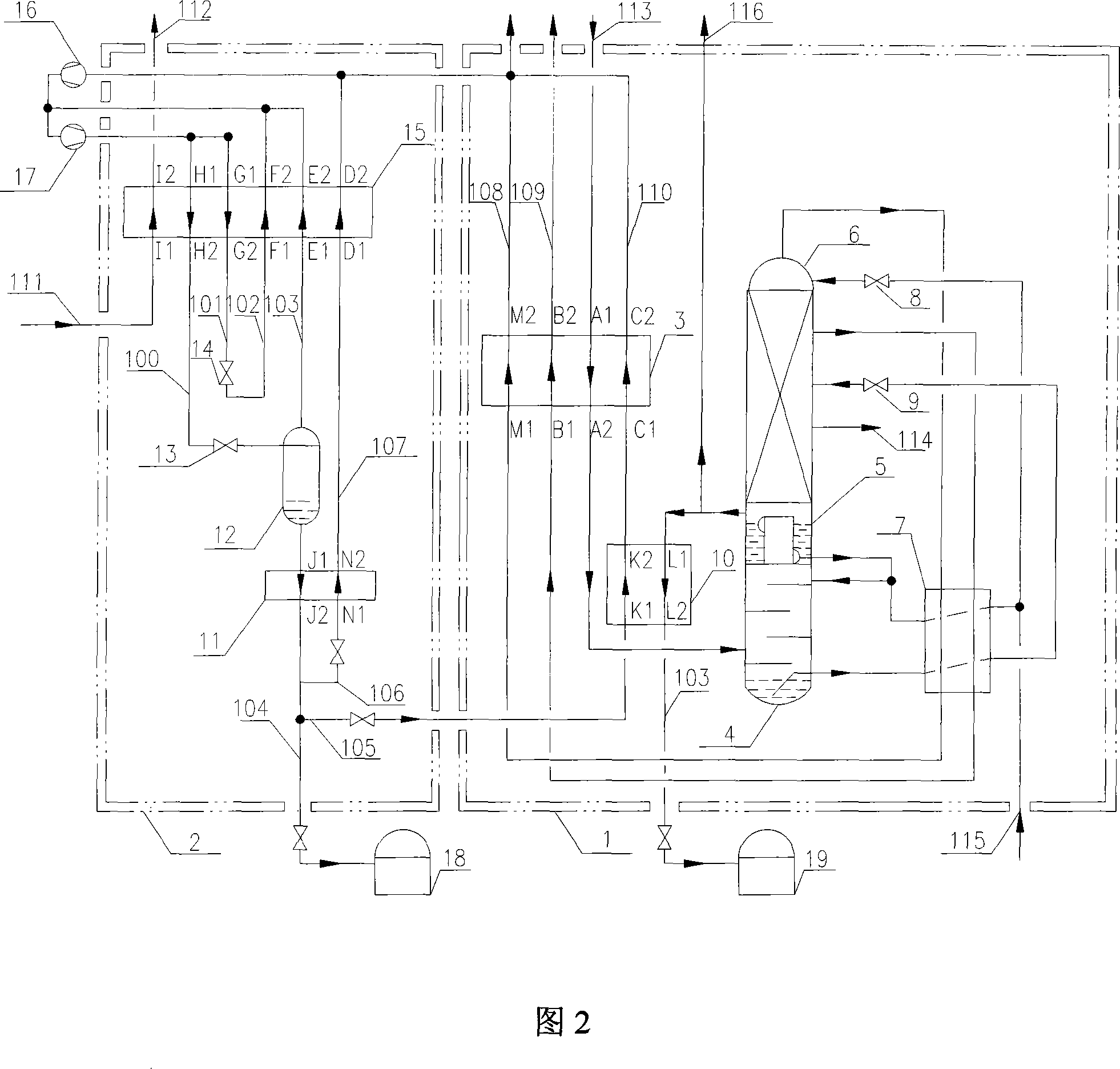

[0041] Example 2. The system and device for separating air by utilizing the cold energy of liquefied natural gas are shown in Figure 2. The difference between this embodiment 2 and the embodiment is that when the supply of liquefied natural gas 111 is insufficient due to an emergency, additional cryogenic liquid can be provided to the device, The cryogenic liquid may be liquid nitrogen.

[0042] When the liquefied natural gas 111 is in short supply due to an emergency, it may be the liquid nitrogen 115 introduced from the outside and sent to the upper fractionation tower. Liquid nitrogen 115 can be directly sent into the fractionation upper tower 6, or can be sent into the fractionation upper tower 6 after being merged with the liquid nitrogen extracted from the fractionation lower tower 4 and passed through the liquid nitrogen liquid-air subcooler 7 and supercooled.

[0043] When the liquefied natural gas 111 is insufficient due to an emergency, the liquid nitrogen 115 intro...

Embodiment 3

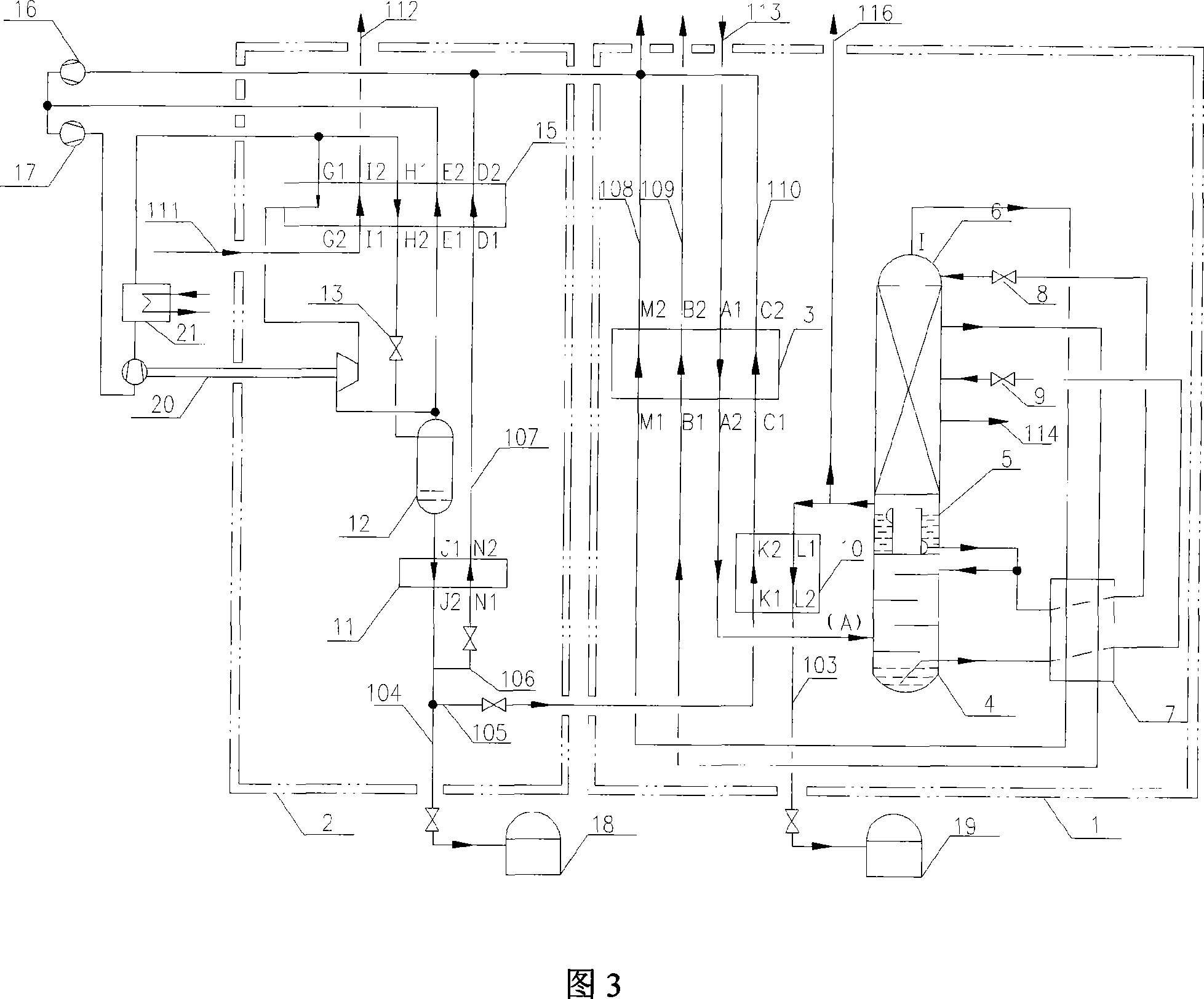

[0044] Example 3. The system and device for separating air by using the cold energy of liquefied natural gas are shown in Figure 3. The difference between this embodiment and Embodiment 1 and Embodiment 2 is that: a booster turbo expander 20 and a water cooler 21 are added. The nitrogen gas coming out from the medium-pressure nitrogen turbine compressor 17 continues to be compressed through the supercharging part of the booster turbo expander 20, which is located outside the cold box II2. After the nitrogen is compressed, it is pre-cooled by the water cooler 21 and divided into two parts. One strand enters the LNG heat exchanger 15, one strand is extracted from the middle of the LNG heat exchanger 15, enters the expansion part of the booster turbo expander 20 to expand and reduce pressure, and merges with the nitrogen gas from the vapor-liquid separator 12 to return to the LNG The heat exchanger 15 reheats and returns to the inlet of the medium-pressure nitrogen turbine compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com