High-yield trichloroacetyl chloride preparation system and method

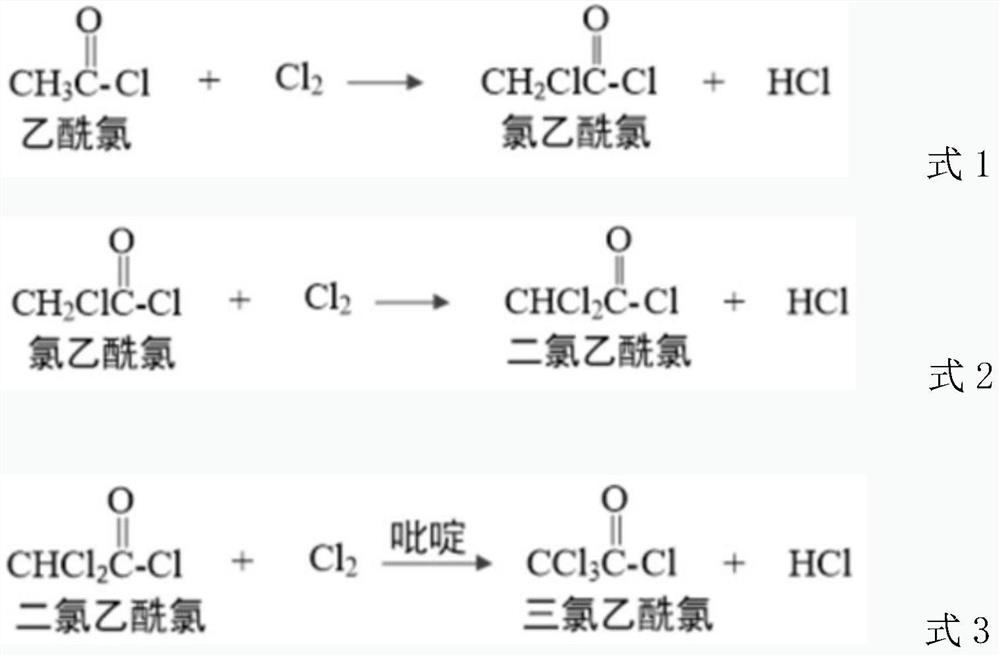

A high-yield technology of trichloroacetyl chloride and trichloroacetyl chloride is applied in the preparation of carboxylates, chemical instruments and methods, preparation of organic compounds, etc., and can solve problems such as low yield of trichloroacetyl chloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

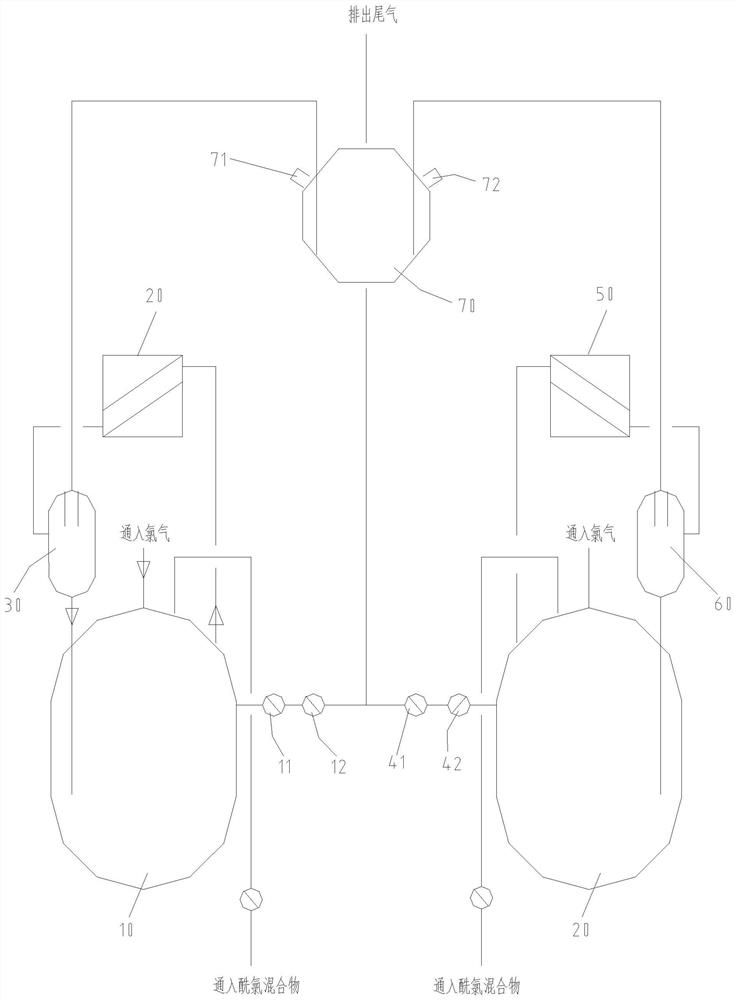

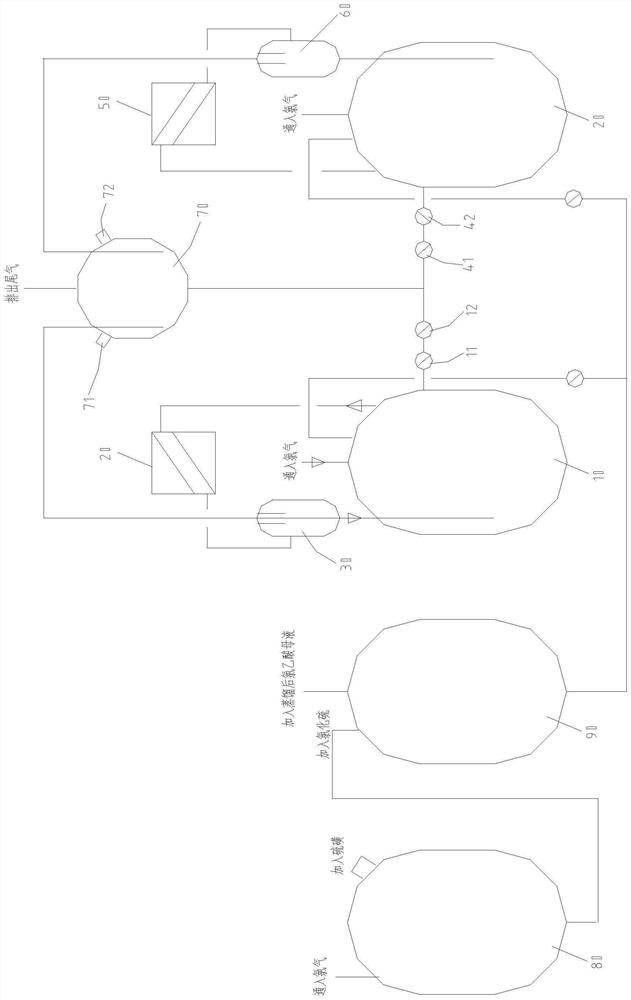

[0018] see figure 1 , the embodiment of the present invention provides a high-yield trichloroacetyl chloride preparation system, comprising a first reaction kettle 10, a first condenser 20, a first solid-liquid separator 30, a second reaction kettle 40, and a second condenser 50. The second solid-liquid separator 60, supplementary tank 70, the acid chloride mixture prepared by the mother liquor of chloroacetic acid is added to the inside of the first reactor 10, the first reactor 10 is provided with holes for feeding chlorine gas, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com