Green synthesis method of methyl-chloride

A technology of green synthesis and methyl sulfide, which is applied in the field of green synthesis of methyl-chloride, can solve the problems of high environmental protection pressure, easy thermal decomposition, and rapid temperature rise of the reaction system, and achieve easy separation, less three wastes, and easy Effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

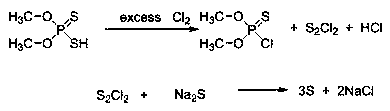

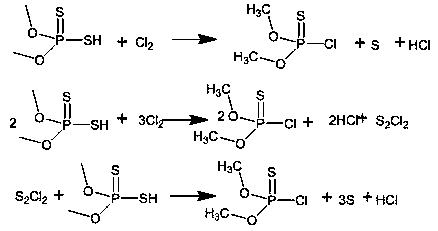

[0032] A kind of green synthetic method of methyl-chloride, comprises the steps:

[0033] S1. In the reaction system for preparing methyl-chloride with methyl sulfide and chlorine as raw materials, the characteristic that disulfur dichloride can be used to chlorinate methyl sulfide is used to control the amount of chlorine introduced to make the reaction The disulfur dichloride produced in the process continues to react with methyl sulfide to convert to methyl-chloride and sulfur;

[0034] S2. After the reaction is completed, add catalyst A and catalyst B to the reaction system to precipitate the sulfur in the system as loose crystals, separate sulfur and methyl-chloride crude products, and obtain high-purity methyl chloride through vacuum distillation. -chloride. In this technical solution, catalysts A and B must be added at the same time, otherwise it is difficult to realize the precipitation of sulfur or the precipitation rate is low, and the properties of sulfur precipita...

Embodiment 1

[0046] A kind of green synthetic method of methyl-chloride of the present invention, comprises the steps:

[0047] (1) Add 150g (98%) methyl sulfide (O,O-dimethyl S-hydrogen-di Thiophosphoric acid ester), 66g of chlorine gas is passed in about 3 hours at 30-40°C, the reaction tail gas (hydrogen chloride) is absorbed by water, and the chlorine flow is completed.

[0048](2) Heat up to 50°C (increase the temperature to increase the subsequent reaction speed), add 2g of sodium hydroxide, keep warm and stir for 1h, add 75g of 4% mass fraction PDS desulfurizer aqueous solution, stir at constant temperature for 1h, then cool down to 20°C (cool down can increase the crystallization speed), after 2 hours of heat preservation, filter to obtain loose crystalline sulfur, and separate the liquid to obtain the crude methyl-chloride. The crude product was transferred to a distillation flask, and rectified at -0.099 MPa high vacuum at 60°C to obtain 136.2 g of methyl-chloride (purity 99%), ...

Embodiment 2

[0050] A kind of green synthetic method of methyl-chloride of the present invention, comprises the steps:

[0051] (1) Add 300g (98%) methyl sulfide (O,O-dimethyl S-hydrogen-di Phosphorothioate), 132g of chlorine gas is passed in about 2 hours at 30-40°C, the reaction tail gas is absorbed by water, and the chlorine flow is completed.

[0052] (2) Heat up to 50°C and add 3g of sodium hydroxide, keep stirring and react for 1h, add 200g of 3% mass fraction PDS desulfurizer aqueous solution, stir at constant temperature for 0.5h, then cool down to 20°C, keep warm for 1h and filter to obtain loose crystal sulfur. The liquid was separated to obtain the crude product of methyl-chloride. The crude product was transferred to a distillation flask, and rectified at -0.099 MPa high vacuum at 60°C to obtain 268.8 g of methyl-chloride (purity 99%), yield 90.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com