A kind of preparation method of volatile organic compound waste gas active adsorbent

A technology of organic compounds and active adsorbents, which is applied in the field of preparation of active adsorbents for volatile organic compound waste gas, can solve the problems of high cost, complex process, high energy consumption, etc., achieve long replacement cycle, large adsorption capacity, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

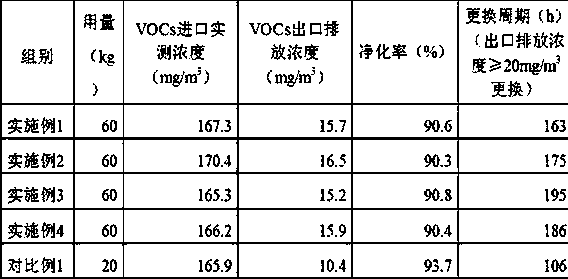

Examples

Embodiment 1

[0015] This example provides a method for preparing an active adsorbent for volatile organic compound waste gas. The components are calculated by weight: 100 parts of circulating fluidized bed coal-fired boiler fly ash, 5 parts of sulfur, 1 part of disulfur dichloride, Sulfur is heated to 460-480°C to form superheated sulfur vapor, which enters the activation prilling tower at a flow rate of 2-3m / s and is mixed with disulfur dichloride at -20--15°C and the circulating flow sent from the bottom of the tower After the exhaust gas from the fluidized bed waste heat boiler is mixed, it is rapidly cooled to below 90°C to form sulfur glue and disulfide dichloride mist droplets. Glue, disulfur dichloride, and fly ash of circulating fluidized bed coal-fired boiler are fully mixed under the purge of exhaust gas from circulating fluidized bed waste heat boiler and spirally rise in the activated prilling tower. Sulfur gum, disulfur dichloride The mist droplets bond the circulating fluidiz...

Embodiment 2

[0017] This example provides a method for preparing an active adsorbent for waste gas of volatile organic compounds. The components are calculated by weight: 100 parts of circulating fluidized bed coal-fired boiler fly ash, 10 parts of sulfur, 1 part of disulfur dichloride, Sulfur is heated to 460-480°C to form superheated sulfur vapor, which enters the activation prilling tower at a flow rate of 2-3m / s and is mixed with disulfur dichloride at -20--15°C and the circulating flow sent from the bottom of the tower After the exhaust gas from the fluidized bed waste heat boiler is mixed, it is rapidly cooled to below 90°C to form sulfur glue and disulfide dichloride mist droplets. Glue, disulfur dichloride, and fly ash of circulating fluidized bed coal-fired boiler are fully mixed under the purge of exhaust gas from circulating fluidized bed waste heat boiler and spirally rise in the activated prilling tower. Sulfur gum, disulfur dichloride The mist droplets bond the circulating fl...

Embodiment 3

[0019] This example provides a method for preparing an active adsorbent for waste gas of volatile organic compounds. The components are calculated by weight: 100 parts of circulating fluidized bed coal-fired boiler fly ash, 5 parts of sulfur, 1.5 parts of disulfur dichloride, Sulfur is heated to 460-480°C to form superheated sulfur vapor, which enters the activation prilling tower at a flow rate of 2-3m / s and is mixed with disulfur dichloride at -20--15°C and the circulating flow sent from the bottom of the tower After the exhaust gas from the fluidized bed waste heat boiler is mixed, it is rapidly cooled to below 90°C to form sulfur glue and disulfide dichloride mist droplets. Glue, disulfur dichloride, and fly ash of circulating fluidized bed coal-fired boiler are fully mixed under the purge of exhaust gas from circulating fluidized bed waste heat boiler and spirally rise in the activated prilling tower. Sulfur gum, disulfur dichloride The mist droplets bond the circulating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com