Environmentally friendly catalyst used for synthesizing sulfur dichloride and preparing method thereof

A technology of sulfur dichloride and catalyst, which is applied in the field of synthesizing sulfur dichloride environment-friendly catalyst, which can solve problems such as low product yield, environmental hazards, and low efficiency, and achieve the effects of reducing difficulty, production cost, and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

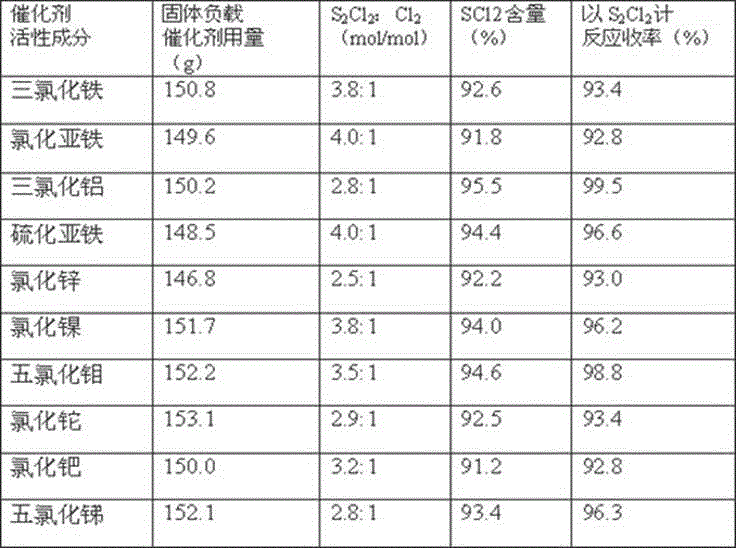

Examples

Embodiment 1

[0020] Add 200g of catalytically active antimony pentachloride catalyst into 160g of water and 640g of ethanol mixed solution, add 200g of 4A spherical molecular sieve to the mixed solution, heat and reflux for 2 hours, so that the catalytically active catalyst is adsorbed in the pores of 4A spherical molecular sieve , the adsorption capacity is 4.55g. After filtering, the antimony pentachloride solid-supported catalyst is obtained; the solid-supported catalyst is dried and dehydrated at 120° C.; after constant weight, the temperature is raised to 300° C. to activate the solid-supported catalyst. After the activation is completed, put it in a dry wide-mouth glass bottle for later use.

Embodiment 2

[0022] Add 280g of catalytically active ferric chloride catalyst into 160g of water and 640g of ethanol mixed solution, add 200g of 4A spherical molecular sieve to the mixed solution, heat and reflux for 6 hours, so that the catalytically active catalyst is adsorbed in the pores of 4A spherical molecular sieve , the adsorption capacity is 3.98g. After filtering, a solid supported catalyst of antimony pentachloride is obtained; the solid supported catalyst is dried and dehydrated at 120° C.; after constant weight, the temperature is raised to 350° C. to activate the solid supported catalyst. After the activation is completed, put it in a dry wide-mouth glass bottle for later use.

Embodiment 3

[0024] Add 240g of catalytically active aluminum trichloride catalyst into 160g of water and 640g of ethanol mixed solution, add 200g of 4A spherical molecular sieve to the mixed solution, heat and reflux for 4 hours, so that the catalytically active catalyst is adsorbed in the pores of 4A spherical molecular sieve , the adsorption capacity is 4.22g. After filtering, the antimony pentachloride solid-supported catalyst is obtained; the solid-supported catalyst is dried and dehydrated at 120°C; after constant weight, the temperature is raised to 320°C to activate the solid-supported catalyst. After the activation is completed, put it in a dry wide-mouth glass bottle for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com