Process device for preparing hypersorber for volatile organic compound waste gas

A technology of organic compounds and active adsorbents, which is applied in the field of preparation of volatile organic compound waste gas active adsorbent process devices, can solve the problems of high labor intensity for operators, easy production of environmental pollutants, and different process devices, so as to achieve safety Production, high heat transfer rate, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

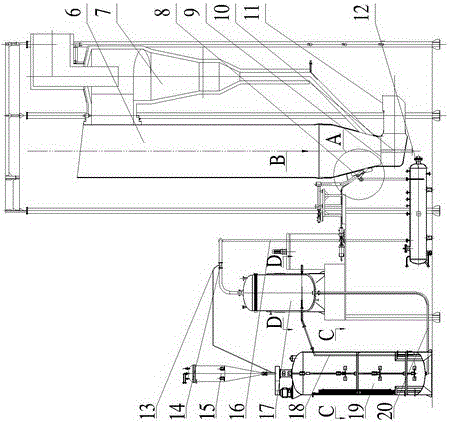

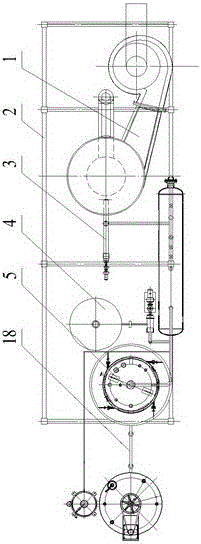

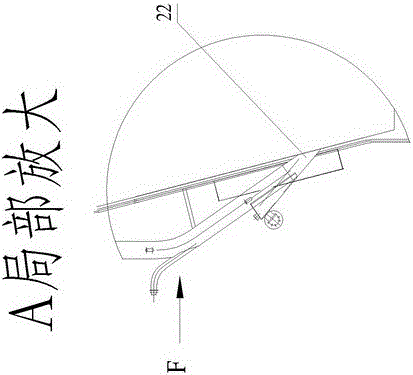

[0030] The device will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] The invention is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, a process device for preparing volatile organic compound waste gas active adsorbent is characterized in that it includes an activated granulation tower 1, a support frame 2, a circulating fluidized bed coal-fired boiler fly ash screw feeder 3, a dichloride Disulfide storage tank assembly 4, sulfur evaporator 5.

[0032] The activated granulation tower 1 , the circulating fluidized bed coal-fired boiler fly ash screw feeder 3 , the disulfur dichloride storage tank assembly 4 , and the sulfur evaporator 5 are all positioned and installed on the support frame 2 .

[0033] The activated granulation tower 1 includes a blanking pipe 10 , an air distribution plate 9 , a wind cap 21 , a circulating fluidized bed waste heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com