Preparation method of high-efficiency oil suction rubber material

An oil-absorbing rubber and high-efficiency technology is applied in the field of preparation of high-efficiency oil-absorbing rubber materials, which can solve the problems of low oil absorption rate and high price, and achieve the effect of good oil absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

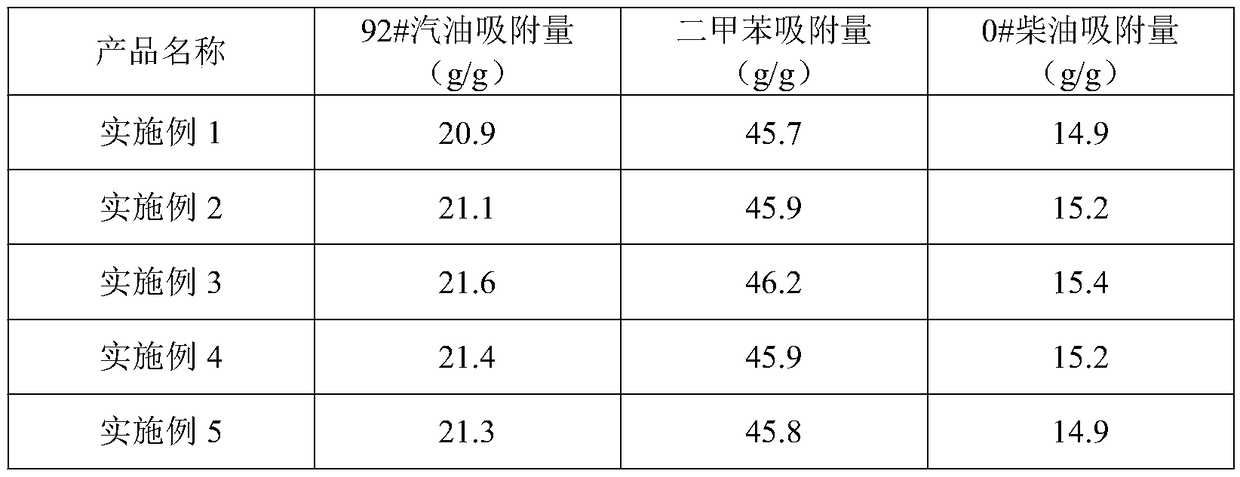

Examples

Embodiment 1

[0029] A preparation method of a high-efficiency oil-absorbing rubber material, the components are calculated in parts by weight, comprising the following steps:

[0030] (1) Add 50 parts of small pieces of natural rubber to the torque rheometer and masticate for 3 minutes, add 5 parts of maleic anhydride monomer and 1 part of dicumyl peroxide, at a reaction temperature of 130 °C and a rotor speed of React for 3 minutes under the condition of 30r / min;

[0031] (2) Put it into a vacuum oven after being purified with acetone for 24 hours in a Soxhlet extractor, and dry at a temperature of 60° C. to obtain a modified natural rubber;

[0032] (3) Mix 50 parts of guayule gum and 100 parts of toluene solution into a three-necked flask equipped with a reflux condenser, a mechanical stirrer and a thermometer, raise the temperature to 65°C, add 5 parts of maleic anhydride monomer, and add 5 parts of maleic anhydride monomer at a speed of 100rpm Stir for 2min;

[0033] (4) Add 3 parts...

Embodiment 2

[0043] A preparation method of a high-efficiency oil-absorbing rubber material, the components are calculated in parts by weight, comprising the following steps:

[0044] (1) Add 70 parts of small pieces of natural rubber to the torque rheometer and masticate for 3 minutes, add 6 parts of maleic anhydride monomer and 1.5 parts of dicumyl peroxide, at a reaction temperature of 130 °C and a rotor speed of React for 3 minutes under the condition of 30r / min;

[0045] (2) Put it into a vacuum oven after being purified with acetone for 24 hours in a Soxhlet extractor, and dry at a temperature of 60° C. to obtain a modified natural rubber;

[0046] (3) Mix 60 parts of guayule gum and 120 parts of toluene solution into a three-necked flask equipped with a reflux condenser, a mechanical stirrer and a thermometer, raise the temperature to 70°C, add 7 parts of maleic anhydride monomer, and add 7 parts of maleic anhydride monomer at a speed of 120rpm Stir for 3 minutes;

[0047] (4) Add...

Embodiment 3

[0057] A preparation method of a high-efficiency oil-absorbing rubber material, the components are calculated in parts by weight, comprising the following steps:

[0058] (1) Add 75 parts of small pieces of natural rubber to the torque rheometer and masticate for 3 minutes, add 8 parts of maleic anhydride monomer and 1.5 parts of dicumyl peroxide, at a reaction temperature of 130 °C and a rotor speed of React for 3 minutes under the condition of 30r / min;

[0059] (2) Put it into a vacuum oven after being purified with acetone for 24 hours in a Soxhlet extractor, and dry at a temperature of 60° C. to obtain a modified natural rubber;

[0060] (3) Mix 75 parts of guayule gum and 150 parts of toluene solution into a three-necked flask equipped with a reflux condenser, a mechanical stirrer and a thermometer, raise the temperature to 70°C, add 8 parts of maleic anhydride monomer, and add 8 parts of maleic anhydride monomer at a speed of 150rpm Stir for 4 minutes;

[0061] (4) Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com