Usage method of processing device for preparing volatile organic compound exhaust gas activated adsorbent

A technology of organic compounds and active adsorbents, which is applied in the field of preparation of volatile organic compound waste gas active adsorbent process devices, can solve the problems of high labor intensity for operators, easy production of environmental pollutants, and different process devices, so as to achieve safety Production, high heat exchange rate, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The device will be further described below in conjunction with the accompanying drawings and specific embodiments.

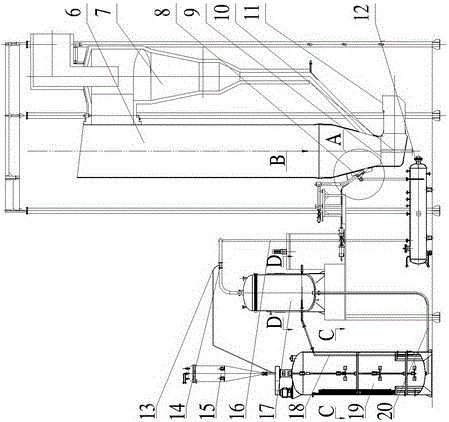

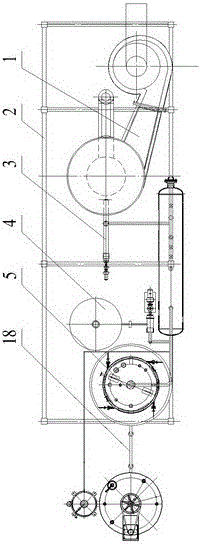

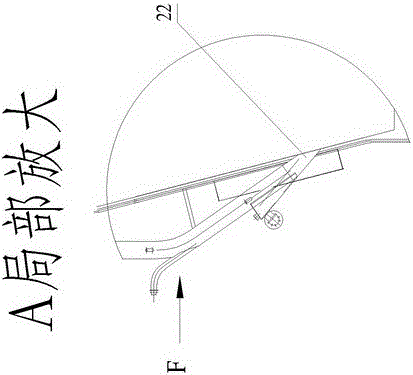

[0032] The invention is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a method for preparing a volatile organic compound waste gas active adsorbent process device is characterized in that: Step 1, using a circulating fluidized bed waste heat boiler with a temperature of 30-35°C and an oxygen content of 5%-9% to discharge tail gas Purge the activated prilling tower 1 on the support frame 2 for 30-60 minutes to reduce the temperature of the activated prilling tower 1 to 30-35°C to prevent overheated sulfur explosion and provide cooling environment temperature; then use nitrogen to blow Sweep the saturated steam heating kettle assembly 19, the hot air heating furnace assembly 17, the superheated sulfur steam buffer tank 12, and the sulfur powder storage tank 15 in the sulfur evaporator 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com