Novel method for absorbing tail gas from trichloro-acetic chloride production through chlorination process

A technology for trichloroacetyl chloride and tail gas absorption, applied in chemical instruments and methods, separation methods, organic chemistry, etc. product and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

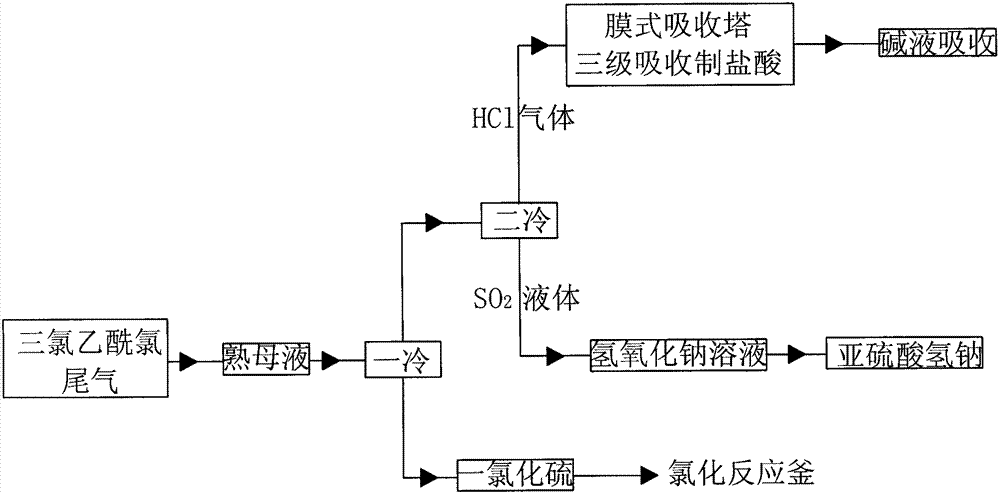

[0016] The technological process of this embodiment sees figure 1 .

[0017] (1) The main and auxiliary chlorination reactors are connected in series, so that the positive and auxiliary tanks are cross-chlorinated, and the chlorine gas enters the main tank (or auxiliary tank) first, and the tail gas after the reaction includes chlorine, sulfur dioxide, sulfur dichloride, a Sulfur chloride, mixed acid chloride, hydrogen chloride, etc. enter the auxiliary tank (or main tank), and the chlorine and sulfur dichloride in the tail gas are absorbed by the auxiliary tank or participate in the reaction;

[0018] (2) The tail gas purified in step (1) includes sulfur dioxide, sulfur monochloride, mixed acid chloride, hydrogen chloride, etc., and the mixed acid chloride and part of the monochloride in the tail gas are absorbed by using the cooked mother liquor (that is, the solution of distilled water from the mother liquor of chloroacetic acid) Sulfur;

[0019] (3) After the tail gas pu...

Embodiment 2

[0024] The technological process of this embodiment sees figure 1 .

[0025] (1) The main and auxiliary chlorination reactors are connected in series, and the positive and auxiliary tanks are cross-chlorinated, and the chlorine gas enters the main tank (or auxiliary tank) first, and the tail gas after the reaction includes chlorine, sulfur dioxide, sulfur dichloride, Sulfur monochloride, mixed acid chloride, hydrogen chloride, etc. enter the auxiliary tank (or main tank), and the chlorine and sulfur dichloride in the tail gas are absorbed by the auxiliary tank or participate in the reaction;

[0026] (2) The tail gas purified in step (1) includes sulfur dioxide, sulfur monochloride, mixed acid chloride, hydrogen chloride, etc., and the mixed acid chloride and part of the monochloride in the tail gas are absorbed by using the cooked mother liquor (that is, the solution of distilled water from the mother liquor of chloroacetic acid) Sulfur;

[0027] (3) After the tail gas puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com