Waste concrete powder paint and preparation method thereof

A technology of waste concrete and powder coatings, applied in the direction of coating, etc., can solve the problems of soil and air pollution, occupying large land, etc., and achieve the effects of increasing added value, good coating properties, and saving natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment one, the preparation of waste concrete powder coating

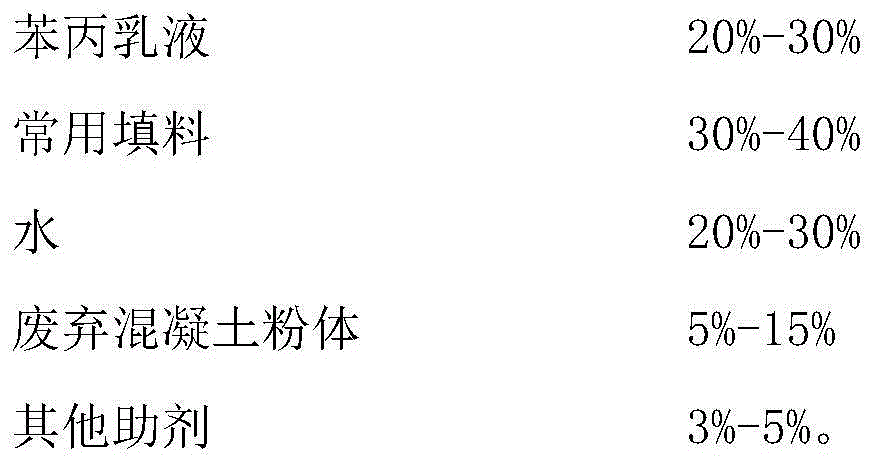

[0038] A kind of waste concrete powder coating, the mass percentage of each component is shown in the product in table 1. (the percentages described in the present invention are all mass percentages)

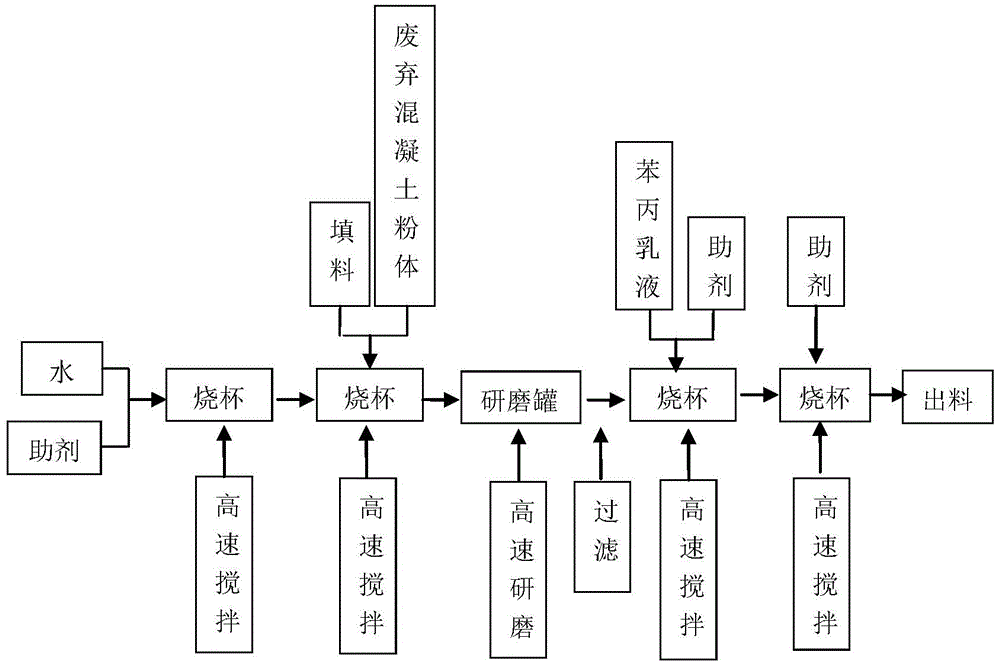

[0039] Such as figure 1 Shown, the preparation steps of waste concrete powder coating of the present invention are specifically as follows:

[0040] (1) Take each raw material according to the formula in Table 1, first add water, dispersant, wetting agent, defoamer, film-forming aid, and 90% ethylene glycol into the beaker, and stir at a high speed of 1000r / min with a mixer 15 minutes;

[0041] (2) Weigh titanium dioxide, heavy calcium carbonate, waste concrete powder, kaolin, and wollastonite with particles larger than 800 mesh and add them to the above solution, stir at high speed to make them disperse evenly without agglomeration;

[0042] (3) Then the solution obtained in step (2) was ground at 200...

Embodiment 2

[0046] Embodiment two, the performance of waste concrete powder coating

[0047] The performance test results of the waste concrete powder coating prepared according to the present invention are shown in Table 2. Among them, the constructability of the coating is carried out according to GB / T 9755; the adhesion test of the coating film is carried out according to GB / T 1720; the hardness of the coating film is carried out according to GB / T 1730; / T 1733, the alkali resistance is measured according to GB / T 9265, and the scrub resistance is measured according to GB / T9266.

[0048] Table 1 Product formula

[0049]

[0050] Among them, 1# product - additives: 1% leveling agent, 1% dispersant, 1% wetting agent, 1% defoamer, 0.5% film-forming aid, 0.3% ethylene glycol, thickener 0.1%, AMP-950.1%; filler: titanium dioxide 9%, heavy calcium carbonate 9%, kaolin 8.1%, wollastonite powder 8.1%.

[0051] 2# product - additives: 1% leveling agent, 0.9% dispersant, 1% wetting agent, 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com