Preparation method of manganese-based MOF (metal-organic framework) magnetic material

An organic framework and magnetic material technology, applied in the field of materials science, can solve the problems of low catalytic efficiency of catalysts, difficult to recycle, etc., and achieve the effects of difficult recycling, improved catalytic performance, and easy magnetic recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

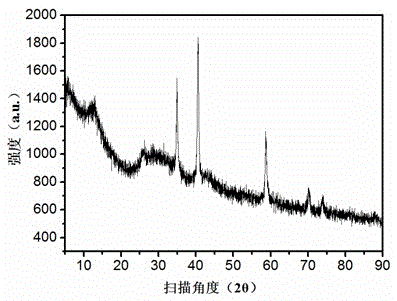

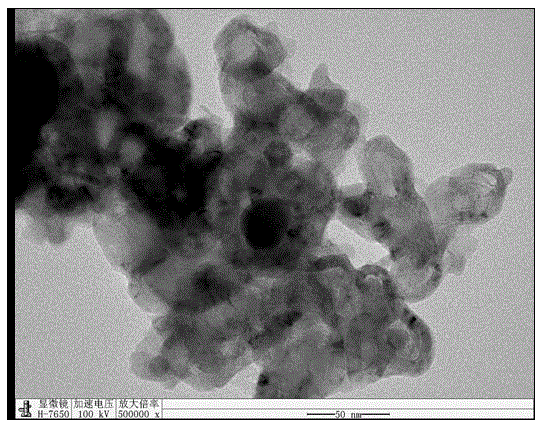

Image

Examples

Embodiment 1

[0019] A method for preparing a manganese-based metal-organic framework magnetic material, specifically comprising the following steps:

[0020] (1) Dissolving 8-hydroxyquinoline in absolute ethanol to form a solution A with a concentration of 10mol / L;

[0021] (2) Dissolve the manganese salt in water to form a 5mol / L solution B, then add the above solution A to the solution B dropwise at a rate of 0.5mL / min, and reflux at 200°C for 2h after the dropwise addition;

[0022] The manganese salt is manganese chloride;

[0023] (3) Control the rotating speed to 5000r / min, centrifuge for 15min, wash the obtained precipitate and dry it. The obtained precipitate was washed 4 times with absolute ethanol and water successively, and then vacuum-dried at a temperature of 60° C. for 12 hours;

[0024] (4) The solid obtained after drying is heated up to 500° C. for 9 hours at a rate of 1° C. / min in a hydrogen atmosphere and calcined for 9 hours to obtain a manganese-based metal-organic fr...

Embodiment 2

[0035] A method for preparing a manganese-based metal-organic framework magnetic material, specifically comprising the following steps:

[0036] (1), 8-hydroxyquinoline was dissolved in absolute ethanol to form a solution A with a concentration of 20mol / L;

[0037] (2) Dissolve the manganese salt in water to form a 5mol / L solution B, then add the above solution A to the solution B dropwise at a rate of 5mL / min, and reflux at 100°C for 8h after the dropwise addition;

[0038] The manganese salt is manganese acetate;

[0039] (3) Control the rotating speed to 10000r / min, centrifuge for 5min, wash the obtained precipitate and dry it. The obtained precipitate was washed 4 times with absolute ethanol and water successively, and then vacuum-dried at a temperature of 60° C. for 12 hours;

[0040] (4) The solid obtained after drying is heated up to 900° C. for 3 hours at a rate of 1° C. / min in a hydrogen atmosphere and calcined for 3 hours to obtain a manganese-based metal-organic f...

Embodiment 3

[0042] A method for preparing a manganese-based metal-organic framework magnetic material, specifically comprising the following steps:

[0043] (1) Dissolving 8-hydroxyquinoline in absolute ethanol to form a solution A with a concentration of 10mol / L;

[0044] (2) Dissolve the manganese salt in water to form 8mol / L solution B, then add the above solution A to solution B dropwise at a rate of 3mL / min, and reflux at 180°C for 5h after the dropwise addition;

[0045] The manganese salt is manganese sulfate;

[0046] (3) Control the rotating speed to 8000r / min, centrifuge for 10min, wash the obtained precipitate and dry it. The obtained precipitate was successively washed with absolute ethanol and water for 5 times, and then vacuum-dried at a temperature of 60° C. for 12 hours;

[0047] (4) The solid obtained after drying is heated up to 500-900° C. for 3-9 hours at a rate of 1° C. / min in a hydrogen atmosphere to obtain a manganese-based metal-organic framework magnetic material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com