Method for treating chemical nickel plating waste water on basis of ozonation and biochemical technique

A technology of chemical nickel plating and technical treatment, applied in chemical instruments and methods, oxidized water/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of total nitrogen not up to standard, and achieve the effect of high disposal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

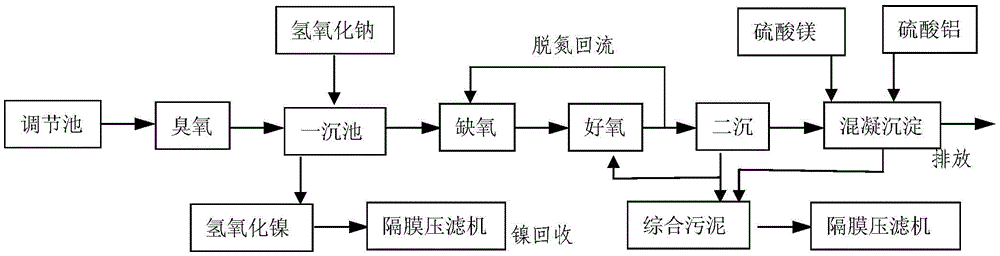

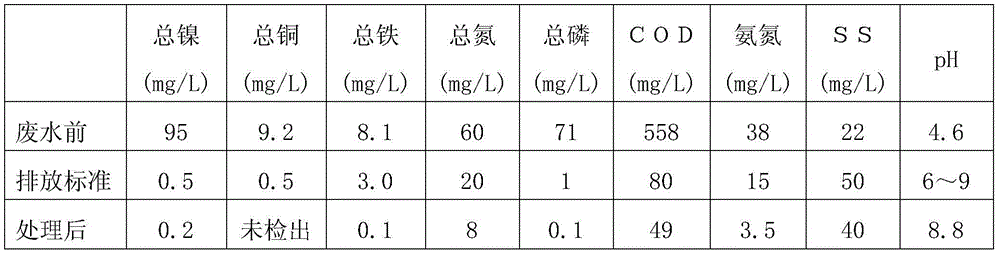

[0024] The method of treating electroless nickel plating wastewater based on ozone oxidation and biochemical technology, the wastewater quality is: total nickel = 60-100mg / L, total copper = 5-10mg / L, total phosphorus = 40-80mg / L, total nitrogen = 50- 60mg / L, total iron=5~12mg / L, COD=500~600mg / L, ammonia nitrogen=30~40mg / L, pH=4~5.

[0025] The electroless nickel plating wastewater enters the wastewater regulating tank, and is oxidized with ozone for 40 minutes to oxidize and destroy part of the complexing agent that forms a coordination with nickel, and simultaneously oxidize hypophosphite and phosphite to orthophosphate, and use a small amount of dilute sodium hydroxide for ozone effluent Adjust the pH of the wastewater to 8.5-9, and enter a settling tank to precipitate nickel hydroxide. The effluent from the first settling tank enters the anoxic biochemical tank with a hydraulic retention time of 8 hours. Under the action of facultative bacteria, the chain breaks to degrade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com