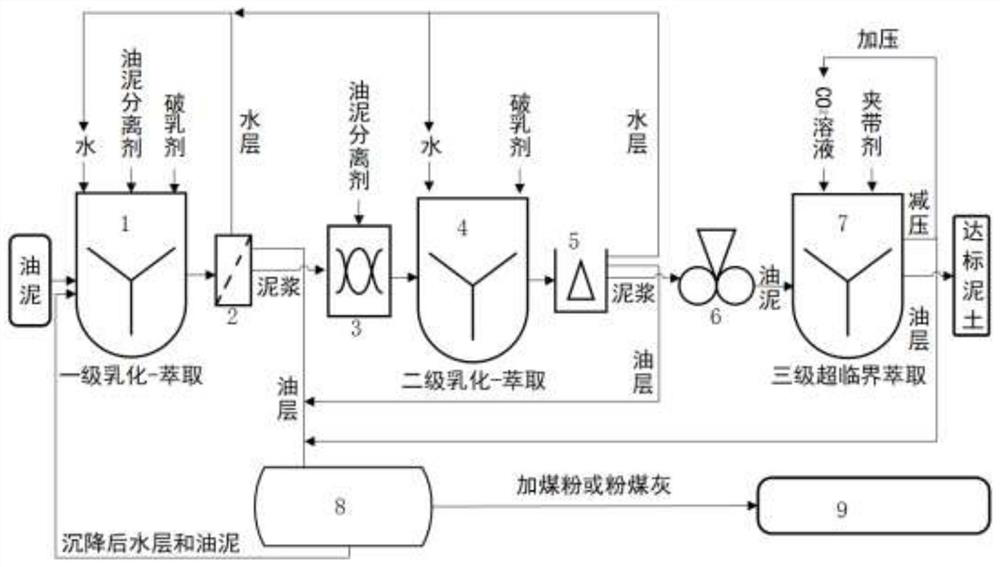

Method for gradient extraction treatment of oily sludge

An oil sludge and extraction technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of unspecified oil content and high oil content of oil sludge, and achieve high cost-effective disposal costs. , good effect, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

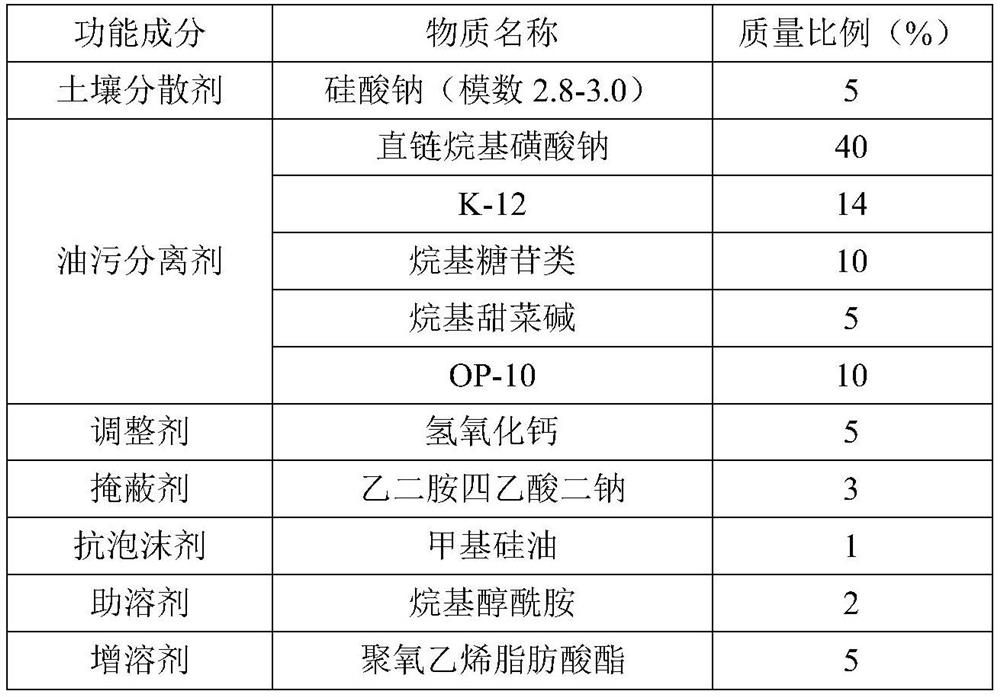

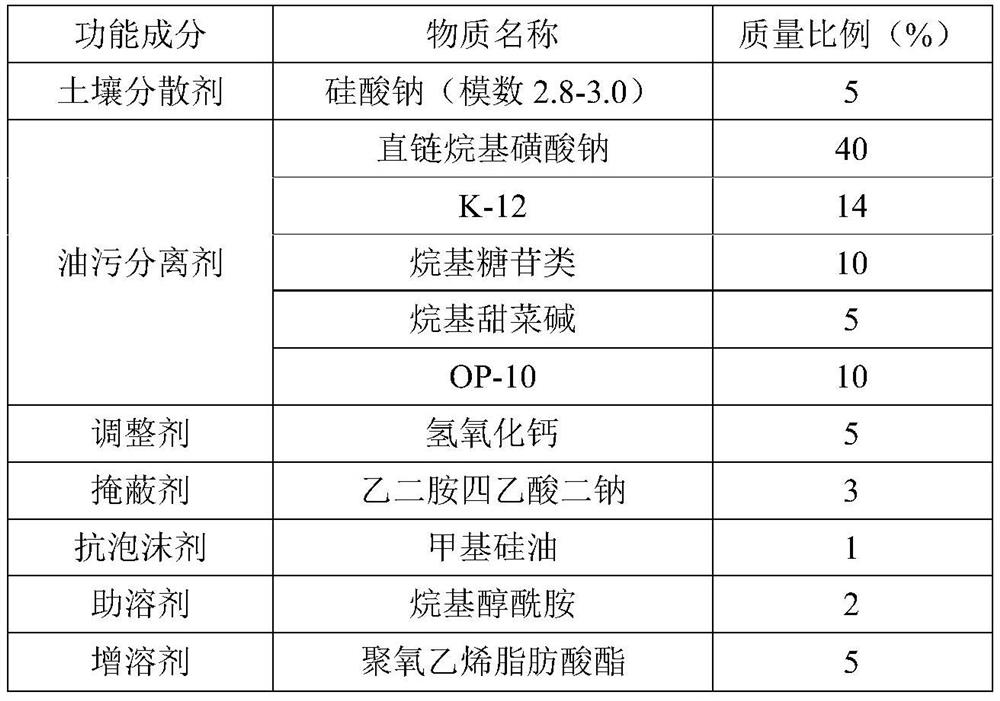

[0037] The specific embodiment of the present invention is described by taking the oil sludge of a refinery as an example. Oil sludge contains 12.3% oil, 38% water, and the rest is solid matter.

[0038]Weigh 4-5kg of water and 0.5kg of sludge separating agent, put them in a blender, heat to 80°C, stir until the sludge separating agent is completely dissolved, weigh 10kg of the above sludge, remove large particles and foreign matter, and add it to the stirrer , Stir at 60°C for 25 minutes, add 50g of demulsifier, stir and stand still to separate oil, mud, and water. The separated oil enters the oil layer storage tank, and the water enters the primary and secondary emulsification-extraction recycling. Add 0.25kg of oil sludge separating agent to the mud, input it into the sludge cutting machine for high-speed cutting, and then enter the homogenizer with 5kg of water, homogenize at 70°C for 15 minutes, then add 50g of demulsifier, and enter the three-phase horizontal screw machi...

specific Embodiment 2

[0040] The specific embodiment of the present invention is illustrated by choosing the oily sludge from an oil field. Oil sludge contains 8.27% oil, 44% water, and the rest is solid matter.

[0041] After pre-removing the larger stones, branches and domestic garbage in the oil sludge, the treatment process, process parameters and the proportion of additives are the same as in Example 1. "After cascade extraction treatment, the mineral oil content in the sludge is 0.17%, the water content is 14.8%, and there is no obvious extractant smell. The total weight of the treated sludge is 6.3kg, and the weight of the treated sludge is reduced by 37%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com