Solid-state electrolyte with negative electrode interface layer, preparation method and solid-state battery

A solid-state electrolyte and solid-state battery technology, which is applied in the direction of non-aqueous electrolyte batteries, solid electrolytes, non-aqueous electrolytes, etc., can solve the problems of high energy consumption, complex process, and poor compatibility of lithium metal in the negative electrode, and achieve low energy consumption and high production efficiency. The process is simple and the effect of reducing the negative electrode interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method comprises the following steps:

[0039] Deposit the indium gallium tin liquid metal alloy on the surface of the polished solid electrolyte, and after leveling, the indium gallium tin liquid metal alloy forms an indium gallium tin liquid metal alloy layer on the surface of the solid electrolyte to obtain a solid electrolyte with a negative interface layer .

[0040] Among them, the indium gallium tin liquid metal alloy can be prepared by the following method, mixing indium, gallium, and tin with a purity of not less than 98% according to the required mass ratio to obtain a mixed material of indium gallium tin, and then heating the mixed material to (1100-1300)°C, keep warm for (30-120) min to obtain the indium-gallium-tin liquid metal alloy, and then naturally cool to room temperature for use. The specific adding temperature can be 1100°C, 1150°C, 1200°C, 1250°C, 1300°C, etc.

[0041] Preferably, according to the mass ratio, the mass ratio of gal...

Embodiment 1

[0047] A solid-state electrolyte with a negative electrode interface layer, a preparation method thereof, and a solid-state battery. Wherein the preparation method of the solid state electrolyte with negative interface layer comprises the following steps:

[0048] S11. Use 2000-grit sandpaper to polish the garnet oxide solid electrolyte as the substrate to a thickness of 800 μm, and use an automatic polishing machine with a cotton self-adsorption abrasive disc to mechanically polish the surface.

[0049] S12. According to the three metals of indium, gallium and tin, according to the mass ratio of 2:8.8:1, weigh 2g of indium with a purity of not less than 98%, 8.8g of gallium with a purity of not less than 98%, and Tin 1.0g, after mixing the three, heat at 1200°C for 60min to obtain an indium-gallium-tin liquid metal alloy, which remains liquid when cooled to room temperature.

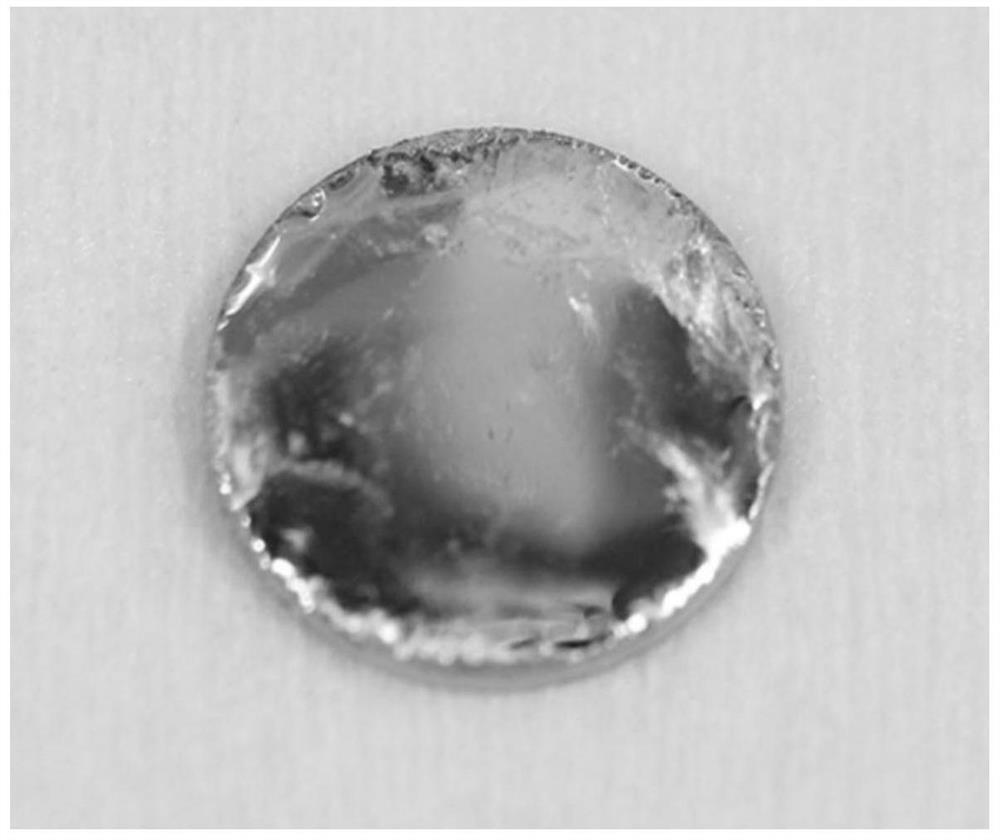

[0050] S13. Take 1 μL indium gallium tin liquid metal alloy, drop it on the polished surface of the...

Embodiment 2

[0054] A solid-state electrolyte with a negative electrode interface layer, a preparation method thereof, and a solid-state battery. Wherein the preparation method of the solid state electrolyte with negative interface layer comprises the following steps:

[0055] S21. Use 2000-grit sandpaper to grind the garnet oxide solid electrolyte as the substrate to a thickness of 800 μm and polish the surface.

[0056] S22. According to the three metals of indium, gallium and tin, according to the mass ratio of 2:8.8:1, weigh 2g of indium with a purity of not less than 98%, 8.8g of gallium with a purity of not less than 98%, and Tin 1.0g, after mixing the three, heat at 1200°C for 60min to obtain an indium-gallium-tin liquid metal alloy, which remains liquid when cooled to room temperature.

[0057] S23. Take 1 μL indium gallium tin liquid metal alloy, drop it on the polished surface of the garnet oxide solid electrolyte disc with a diameter of 15mm as the substrate, and use a scraper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com