Random-direction whole-hole section three-direction rigid coupling sensor installing and recycling device

A technology of any direction and recovery device, applied in the field of transmission, can solve the problems of non-recycling, high monitoring cost, failures that cannot be repaired and replaced, and achieve the effect of convenient operation and difficult recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

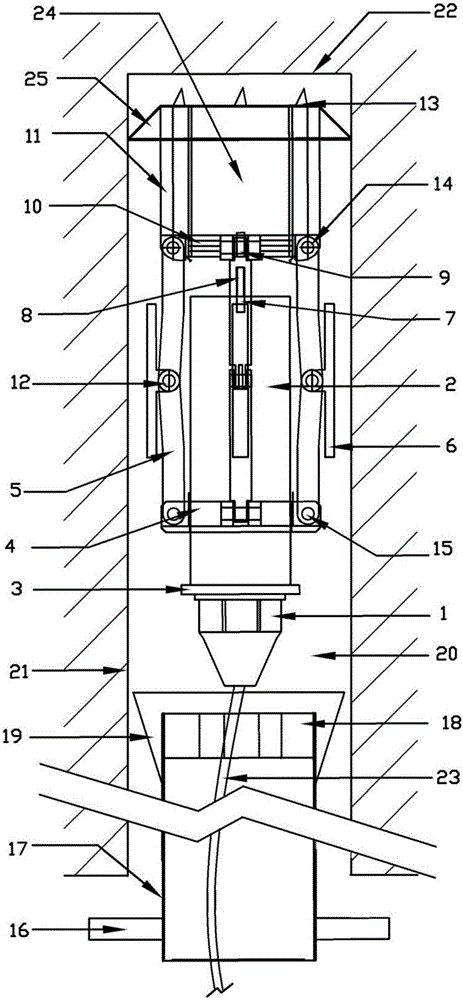

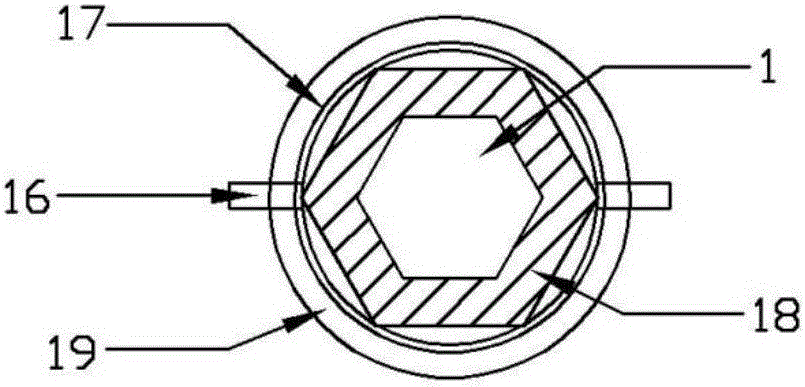

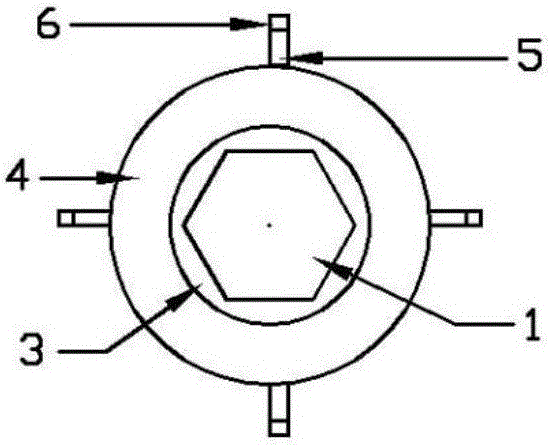

[0015] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0016] A three-way rigid coupling sensor installation and recovery device with full holes in any direction, including a fixed installation recovery device, the fixed installation recovery device includes a base 11, a docking thread base 10 and a push platform 4, and the base 11 is a hollow cylinder with two ends open , the inner wall of the base 11 is provided with a base internal thread, the butt threaded base 10 is circumferentially provided with a threaded base external thread adapted to the base internal thread, the butt threaded base 10 is provided with a butt threaded base hole 9, and one end of the threaded rod 8 passes through the thread It is connected with the hole 9 of the docking threaded base, the other end of the threaded rod 8 is connected with the sensor bottom hole 7 on the sensor 2 through threads, the push platform 4 is set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com