Iron carbon material and preparation method and application thereof

A technology of iron carbon and activated carbon, which is applied in the field of water treatment, can solve the problems of short half-life, easy failure, loss of water purification function, etc., and achieve the effect of accelerating the reduction and degradation speed, increasing the removal capacity, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052]

[0053] A preparation method of iron-carbon material, comprising:

[0054] (1), an activation process for activating granular activated carbon;

[0055] (2), the preparation process of preparing iron carbon material by adopting inorganic iron salt and activated granular activated carbon.

[0056] Wherein, the activation procedure of step (1) can adopt any one of boiling water activation method, ultrasonic activation method and nitric acid activation method.

[0057] The boiling water activation method comprises the following steps:

[0058] a1. Mix granular activated carbon with deionized water, heat to boiling state and keep it for 20-30 minutes;

[0059] a2. Naturally cool to room temperature and place for 5-8 hours;

[0060] a3. Take the precipitate and wash it with deionized water for 2 to 4 times;

[0061] a4. Dry to constant weight at 110-130°C to obtain activated granular activated carbon, and put it into a ground-mouth bottle for later use.

[0062] The ...

Embodiment 1

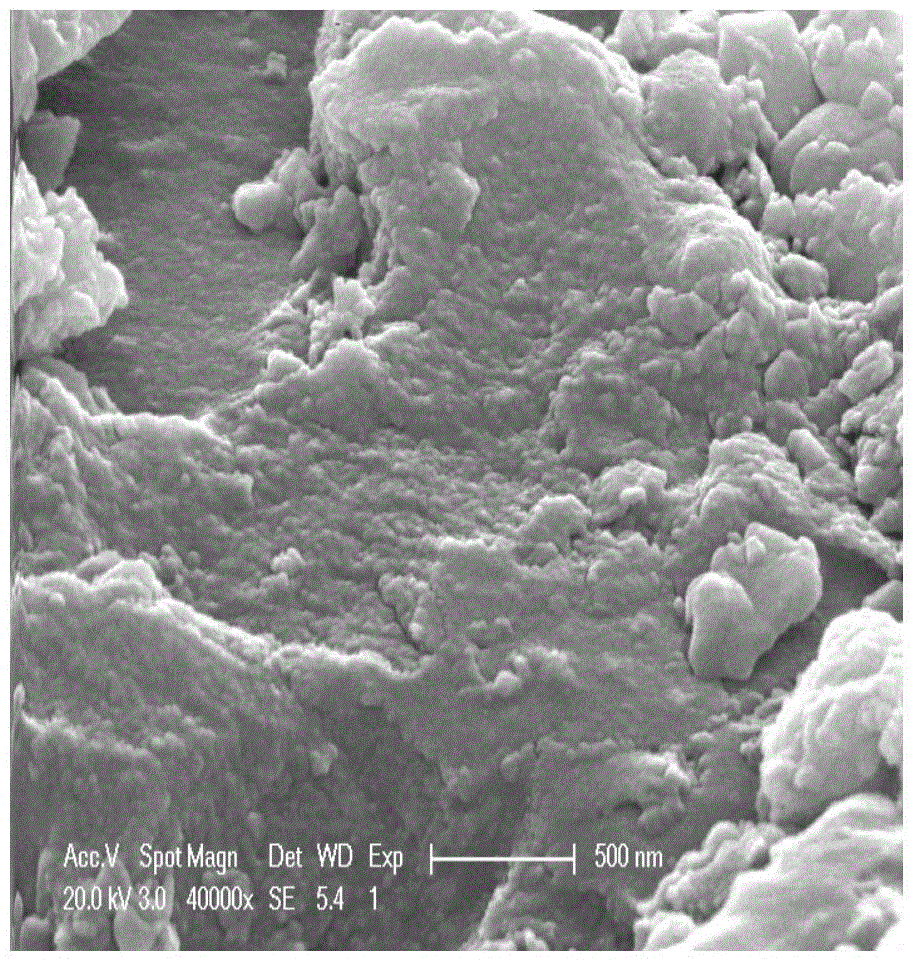

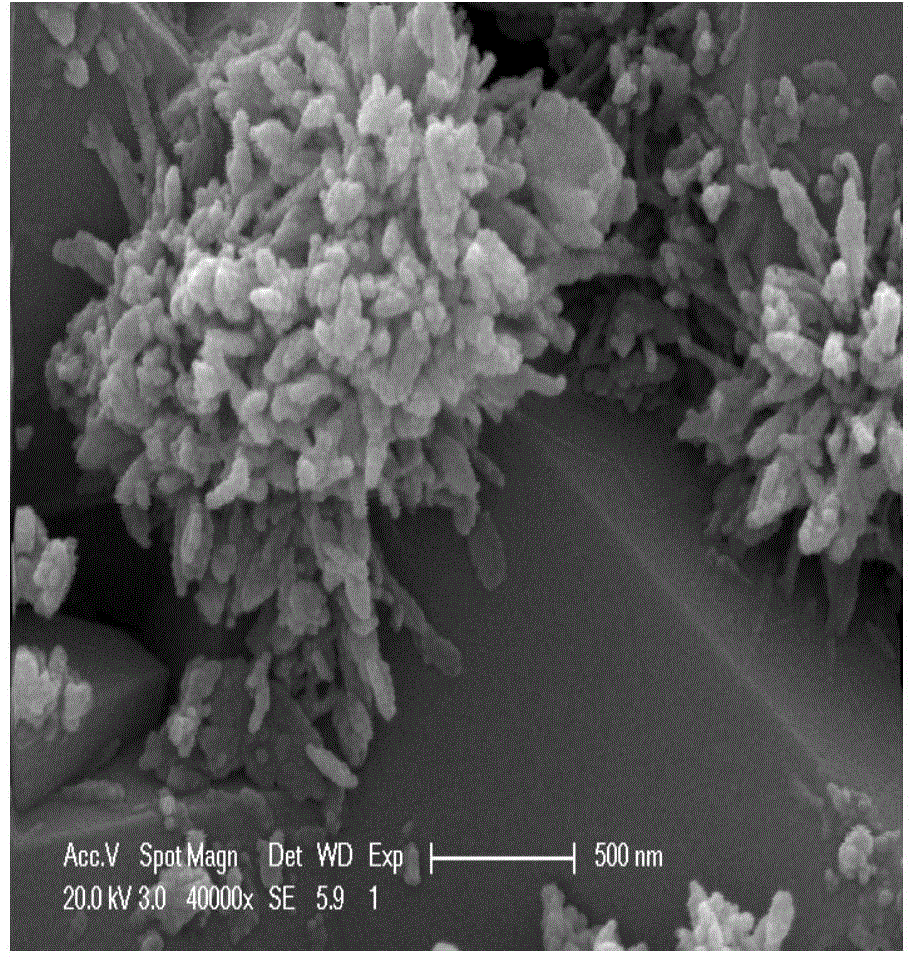

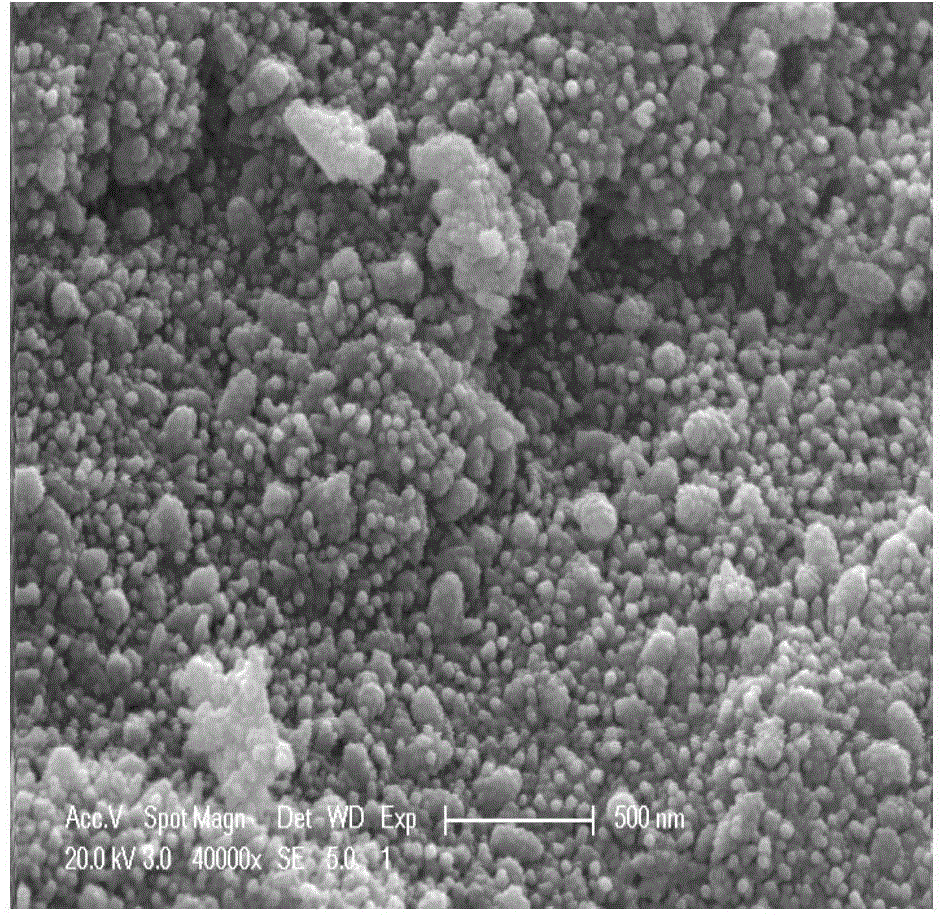

[0076] This embodiment provides an iron-carbon material for reducing and degrading bromate contained in water. The iron-carbon material contains activated carbon and nano-hydroxy iron loaded on the activated carbon, and the nano-hydroxy iron is FeOOH. The mass ratio of activated carbon to nano-hydroxy iron is 1:2.5.

[0077] Among them, this embodiment uses FeSO 4 ·7H 2 O impregnated granular activated carbon prepared as an example to illustrate the nano-hydroxy iron. The bromate removal capacity of nano-hydroxy iron with different iron content is as follows: Figure 7 shown. Figure 7 Denotes the adsorption isotherms of GAC and Fe‐GAC with different iron contents for the removal of bromate after 72 h. Figure 7 The abscissa of represents the initial bromate concentration (Initial bromate concentration), the unit is mmol / L. Figure 7 The vertical axis of represents bromate removal capacity (Bromate removal). From Figure 7 It can be seen that when the iron content is 1...

Embodiment 2

[0079] This embodiment provides a method for preparing an iron-carbon material, which is used to prepare the iron-carbon material in Example 1. This preparation method comprises the steps:

[0080] (1) Mix granular activated carbon with deionized water, heat to boiling state and keep for 35 minutes, cool to room temperature naturally and leave for 6 hours, take the precipitate and wash it with deionized water for 3 times, dry at 120°C to constant weight, The activated granular activated carbon is obtained.

[0081] (2) Mix the inorganic iron salt and the activated granular activated carbon at a mass ratio of 1:2.5, heat at 120°C for 24 hours under the infiltration of deionized water, and wash with deionized water until the cleaned liquid becomes clear , to obtain iron-carbon material after drying.

[0082] Wherein, in the heating process of step (2), it should be ensured that the deionized water does not completely evaporate to dryness, that is, it should be ensured that a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com