Mesoporous zinc ferrite, preparation method thereof, and magnetic carbon nanotube prepared from same

A technology of magnetic carbon nanotubes and mesoporous zinc ferrite, which is applied in separation methods, chemical instruments and methods, iron compounds, etc. problems, to achieve the effect of reducing secondary pollution, good adsorption performance, and efficient recovery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

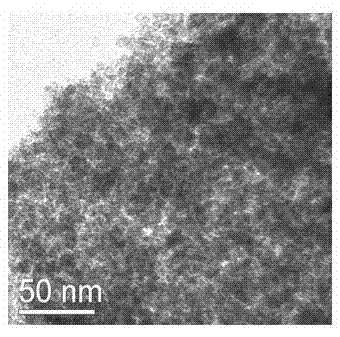

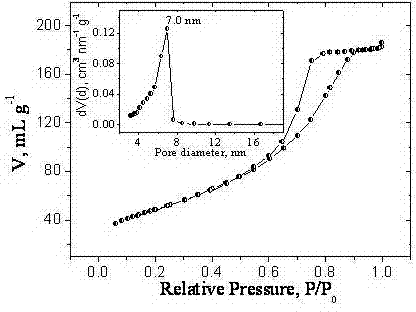

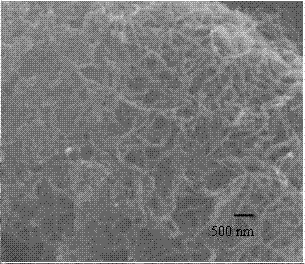

[0042] Embodiment 1: mesoporous zinc ferrite (meso-ZnFe 2 O 4 ) preparation

[0043] 2.08 g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 35 ml of deionized distilled water, and 1.0 g of cetyltrimethylammonium bromide (CTAB) was added, and cetyltrimethylammonium bromide was added, then sonicated for 10-20min, and magnetically stirred for 10- After 20 min, a uniform and clear mixed solution was formed, and 35 ml of 0.4 mol / L Fe(NO 3 ) 3 The solution was stirred under a magnetic stirrer for 30 min, then 6 mol / L NaOH solution was added to adjust the pH value of the mixed solution to 10, and the stirring was continued for 30 min. In a high pressure reactor. Then put it into a vacuum oven and react at 200 °C for 24 h. After the reaction was completed, after natural cooling, the surface liquid was poured out, washed 3 times with deionized water, and then washed 1 time with absolute ethanol. h. The solid was separated by a magnet, washed three times with deionized wa...

Embodiment 2

[0050] Embodiment 2: mesoporous zinc ferrite (meso-ZnFe 2 O 4 ) preparation

[0051] Mesoporous zinc ferrite (meso-ZnFe 2 o 4 ) is prepared using the mesoporous zinc ferrite (meso-ZnFe) described in Example 1 2 o 4 ) of the preparation method, the difference is the use of adding 0.5 g cetyl trimethylammonium bromide. Embodiment prepares gained meso-ZnFe 2 o 4 The particle size is 10-20 nm, the pore size is about 7.8 nm, and the BET area is 132.3 m 2 g -1 .

Embodiment 3

[0052] Embodiment 3: mesoporous zinc ferrite (meso-ZnFe 2 O 4 ) preparation

[0053] Mesoporous zinc ferrite (meso-ZnFe 2 o 4 ) is prepared using the mesoporous zinc ferrite (meso-ZnFe) described in Example 1 2 o 4 ) of the preparation method, the difference is to adopt the addition of 5.0 g cetyltrimethylammonium bromide. Embodiment prepares gained meso-ZnFe 2 o 4 The particle size is 5-10 nm, the pore size is about 6.9 nm, and the BET area is 175.4 m 2 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com