A multi-position adjustable flue gas purification environmental protection equipment

An environmental protection equipment and flue gas purification technology, applied in the field of flue gas purification, can solve the problems of decreased adsorption function of activated carbon particles and poor effect of flue gas purification treatment, etc., and achieve the effects of easy replacement, easy adjustment, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

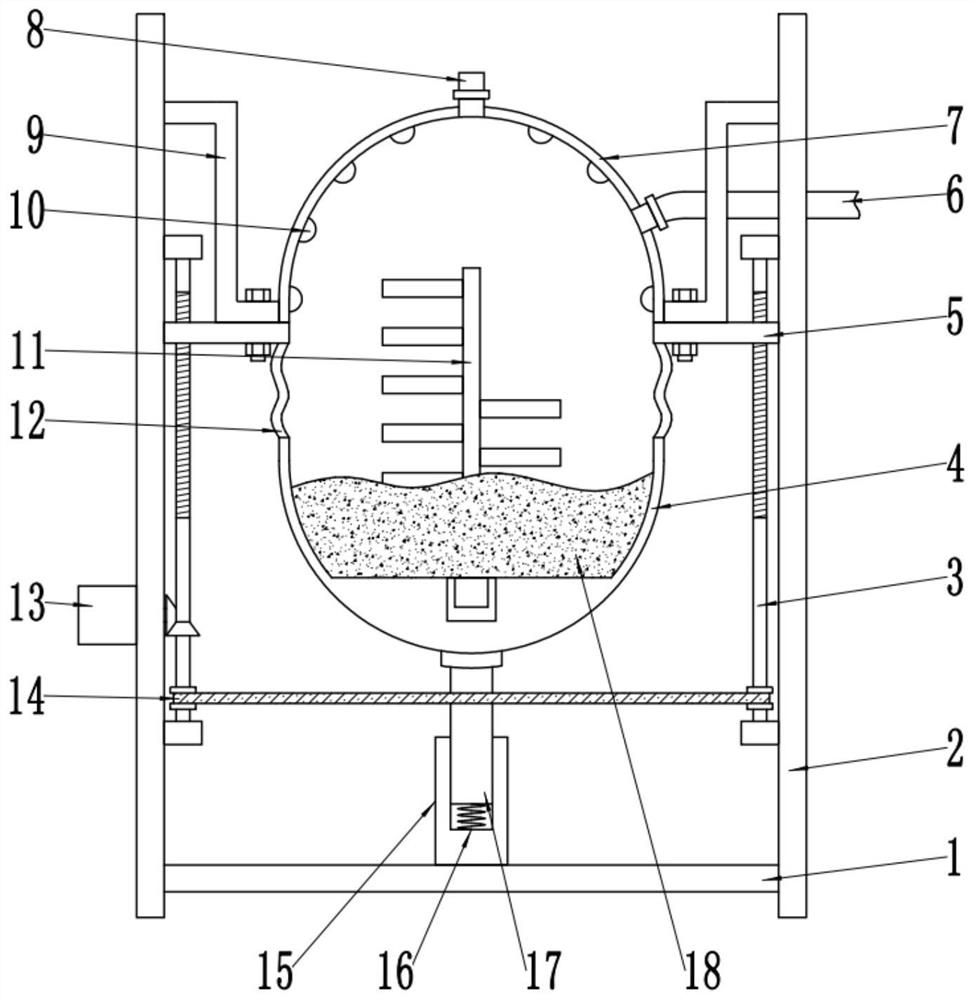

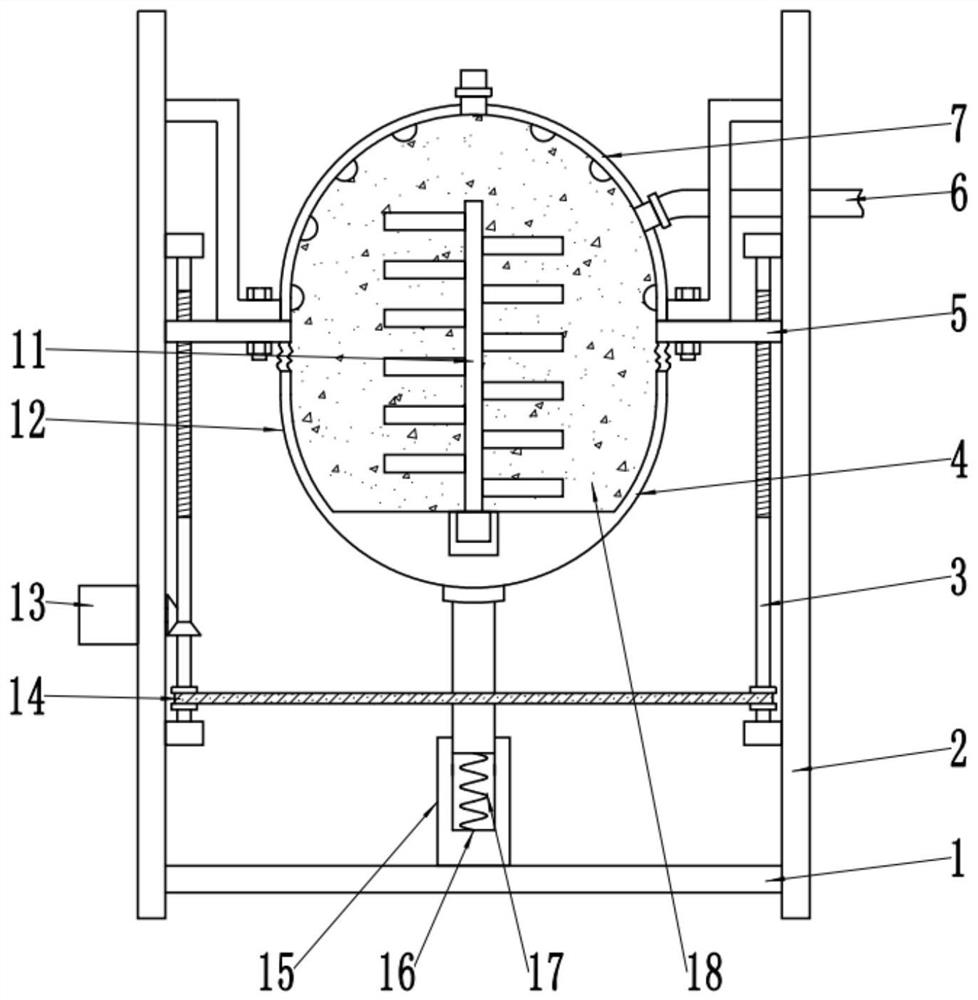

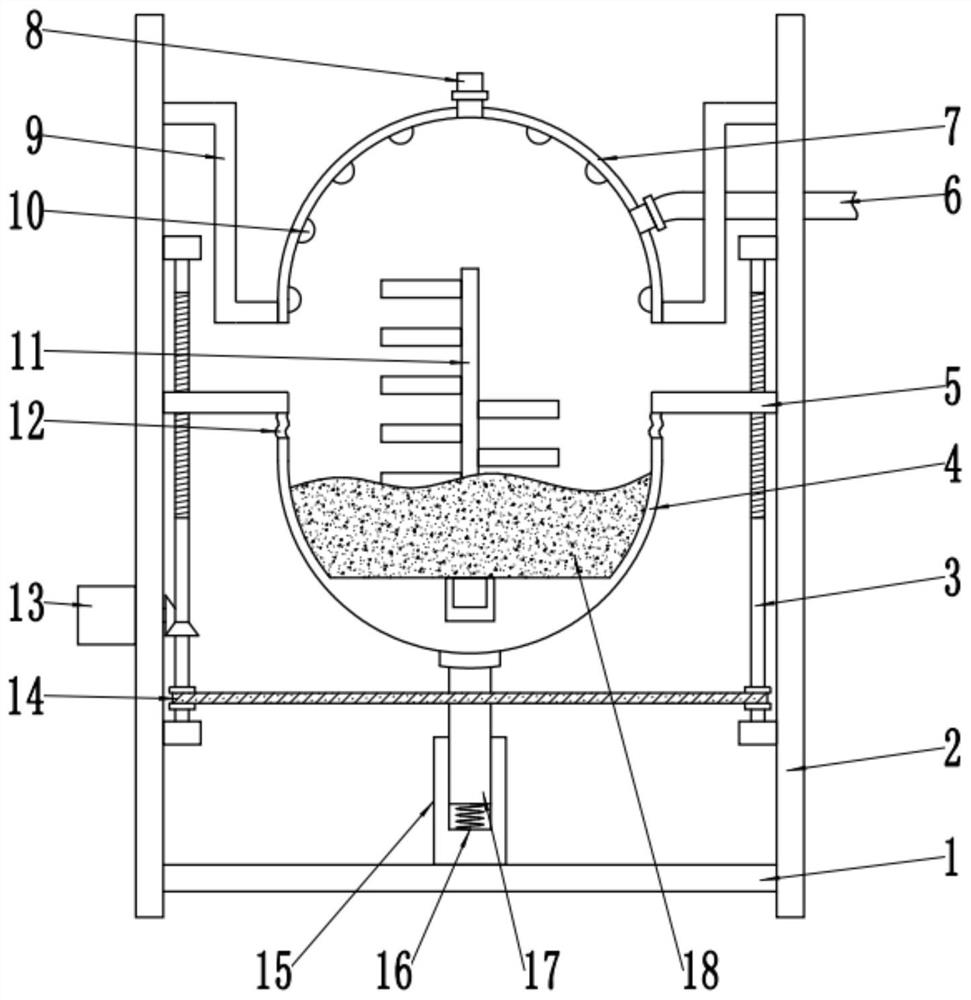

[0032] see Figure 1~5 , in the embodiment of the present invention, a multi-position adjustable flue gas purification and environmental protection equipment includes a bottom plate 1, a lower sphere 4 and an upper sphere 7; two side plates 2 are symmetrically fixed on the left and right sides of the bottom plate 1, The left and right sides of described upper sphere 7 are respectively fixedly connected with two side plates 2 by two brackets 9, and described lower sphere 4 is movably arranged directly below upper sphere 7, and lower sphere 4 and upper sphere 7 are identical in size, The inner hollow hemispherical structure, the opening of the lower sphere 4 is upward, the opening of the upper sphere 7 is downward, and a connecting piece 12 is arranged between the upper sphere 7 and the lower sphere 4, the lower sphere 4, the upper sphere 7 and the connecting piece 12 are spliced to form a Clean chamber for flue gas treatment;

[0033] Specifically, in this embodiment, the co...

Embodiment 2

[0043] see Figure 6 The difference between this embodiment and Embodiment 1 is that the threaded sleeve 5 is fixedly connected with the bracket 9 through the fastening screw 21 to ensure that the connecting piece 12 and the upper sphere 7 are connected in place. In order to prevent the smoke from connecting the connecting piece 12 and the The joint of the upper sphere 7 is discharged, the bracket 9 is equipped with a block 22, the screw sleeve 5 is provided with a slot 24 that cooperates with the block 22, and the junction of the block 22 and the slot 24 is provided with a The sealing strip 23 ensures the airtightness of the joint between the connecting piece 12 and the upper sphere 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com