Preparation method and application of grain stillage-loaded heterogeneous catalyst

A heterogeneous catalyst and distiller's grain technology, which is applied in chemical instruments and methods, water treatment of special compounds, oxidized water/sewage treatment, etc., can solve the problems of many dross, difficult to use, difficult to use distiller's grains, etc., and achieve good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of distiller's grains supported heterogeneous catalyst of the embodiment of the present invention, described method comprises the following steps:

[0025] (1) Soak every 10-50g of dried distiller's grains in 300-1000mL acid solution with a concentration of 1-10% for 1-8h, filter, wash until neutral, and dry; calcined to obtain silicon dioxide;

[0026] (2) immersing the silicon dioxide in a concentration of 10-50% Fe 3+ Stirring in a water bath at 60-100° C. for 1-4 h in the ion solution, separating the solid from the liquid to obtain a solid, and drying the solid to obtain the heterogeneous catalyst supported on distillers grains.

[0027] The distiller's grain raw material in the embodiment of the present invention is calcined under specific conditions to obtain amorphous silica with high purity and high specific surface area, which generally does not contain harmful heavy metal ions such as lead and arsenic.

[0028] Heterogeneous catalyst m...

Embodiment 1

[0035] After the distiller's grains were washed with water for 3 times and dried, 20 g of dried distiller's grains were taken, soaked in 500 mL of 3% dilute hydrochloric acid solution for 2 hours, filtered, washed with deionized water until neutral, and dried for 10 hours. The processed distiller's grains were placed in a muffle furnace and calcined at 400°C for 20 minutes to obtain a silica product. Then immerse the silicon dioxide product in 10% ferric nitrate solution, bathe in water at 60° C. for 1 hour, filter with suction, and dry for 12 hours to obtain distiller’s grains-loaded heterogeneous catalyst.

Embodiment 2

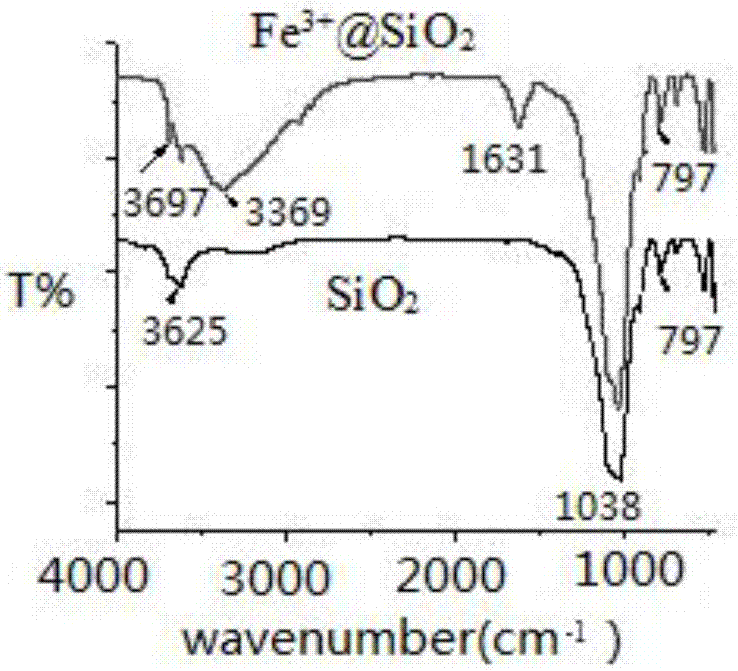

[0037] After the distiller's grains were washed 4 times with water and dried, 30 g of dried distiller's grains were taken, soaked in 500 mL of 5% dilute hydrochloric acid solution for 4 hours, filtered, washed with deionized water until neutral, and dried for 12 hours. The processed distiller's grains were placed in a muffle furnace and calcined at 500° C. for 40 minutes to obtain a silica product. Then immerse the silicon dioxide product in 20% ferric nitrate solution, put it in a water bath at 70°C for 2 hours, filter it with suction, and dry it for 18 hours to obtain a heterogeneous catalyst supported by distiller's grains. figure 1 It is the infrared spectrogram before and after iron loading of the distiller's grains loaded heterogeneous catalyst obtained in Example 2 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com