Nanometer porous metal catalyst and its prepn

A metal catalyst and nanoporous technology, applied in the field of new nanostructured material catalyst and its preparation, can solve the problem of low catalytic activity, and achieve the effects of high specific surface area, promotion of dissolution, and shortened preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Au / Ag alloy with a thickness of 20 microns, a width of 2 centimeters, a length of 5 centimeters, and a gold atomic percentage of 26 at.% is used as an anode, and placed in nitric acid with a concentration of 65 to 66 wt.%.

[0032] (2) At a temperature of 29°C, a two-electrode electrochemical system is used, with gold-silver alloy as the anode and platinum as the counter electrode, and a voltage of 1.1V is applied to perform electrochemical corrosion; the corrosion time is 8 minutes, and the corrosion time is 8 minutes. Black oxidized gold on the surface of the material is the termination indicator;

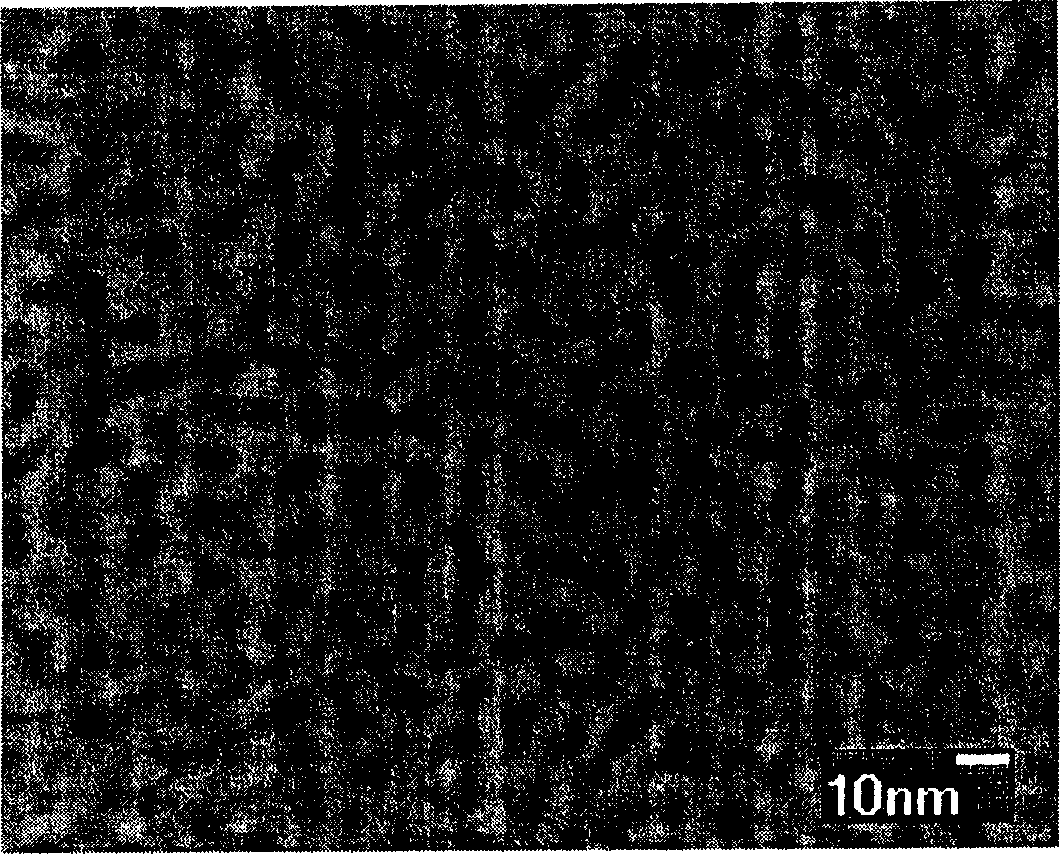

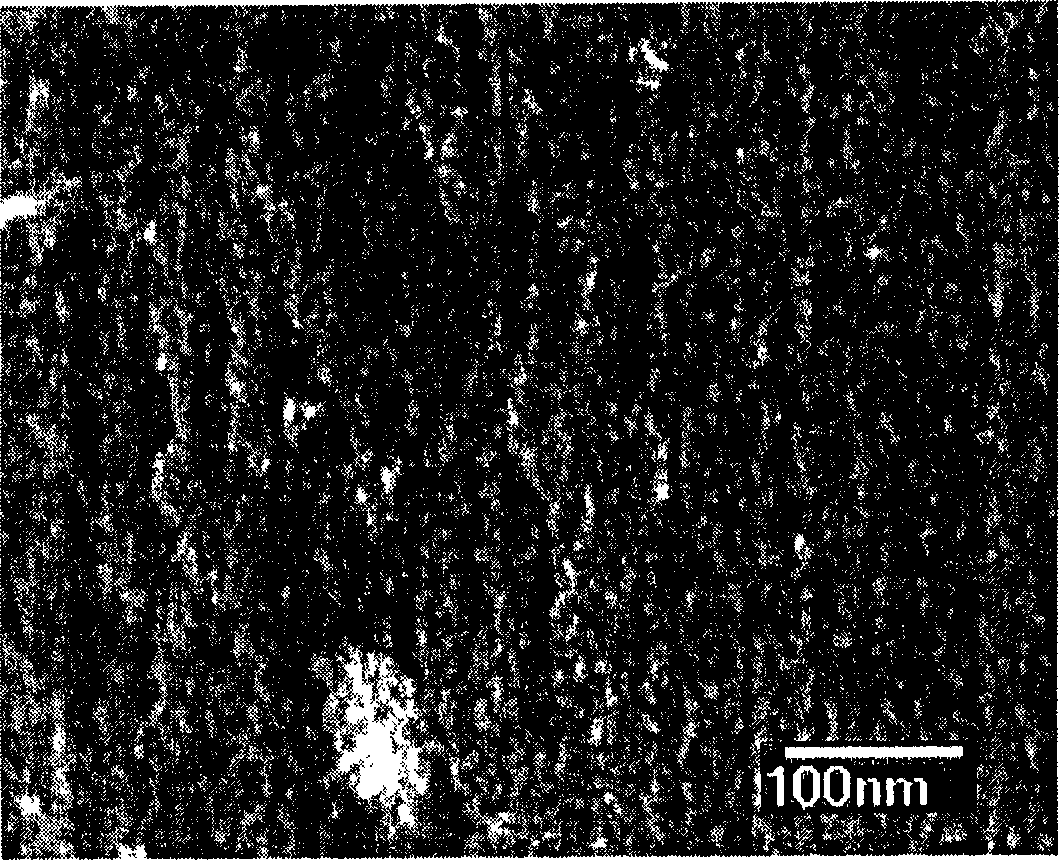

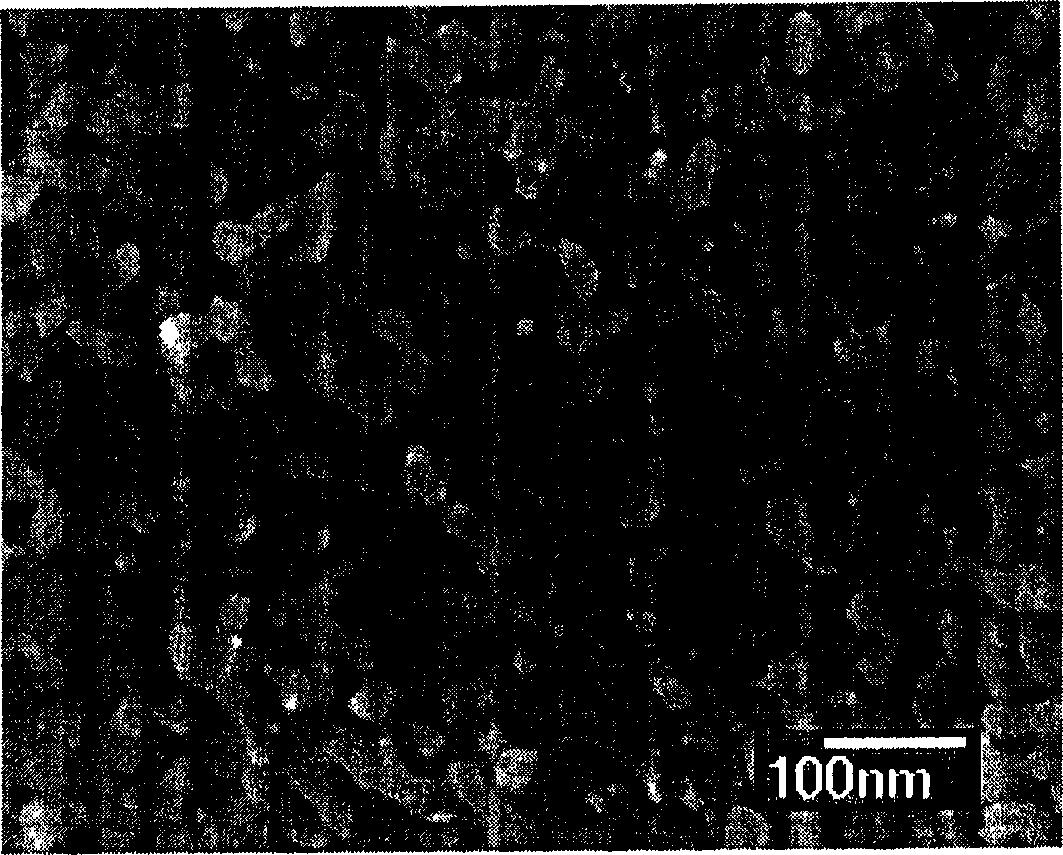

[0033](3) Collect the corroded alloy sheets, wash them repeatedly with ultrapure water until the electrolyte (nitric acid) is completely washed away (the water rinsed with extensive pH test paper is detected to be neutral); then dry at 29°C to obtain Nanoporous metal catalysts. Its scanning electron microscope (SEM) photos are attached figure 1 , the pore wall size i...

Embodiment 2

[0035] In the two-electrode electrochemical system, at a room temperature of 25°C, an Au / Ag alloy with a thickness of 20 microns, a width of 2 cm, a length of 10 cm, and a gold atomic percentage of 26 at.% was selected as the anode, and a platinum sheet was used as the anode. Put the opposite electrode in 66-68wt.% concentrated nitric acid, apply a voltage of 0.8V, corrode for 15 minutes, then wash away the nitric acid with ultra-pure water, use extensive pH test paper to test that the rinsed water is neutral, and then dry it at 25°C , the product pore wall size is about 7 nanometers.

Embodiment 3

[0037] In the two-electrode electrochemical system, at a room temperature of 28°C, an Au / Ag alloy with a thickness of 30 microns, a width of 5 cm, and a length of 18 cm, with a gold atomic percentage of 26 at.% was selected as the anode, and graphite was used as the counter. Put the electrode into 66-68wt.% concentrated nitric acid, apply a voltage of 1.0V, corrode for 20 minutes, then wash away the nitric acid with ultra-pure water, use extensive pH test paper to detect that the rinsed water is neutral, and then dry it at 28°C. The pore wall size of the product is about 7 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com