Preparation method of pumice-loaded zinc oxide hydroxide

A zinc oxyhydroxide and pumice technology, applied in chemical instruments and methods, catalyst carriers, chemical/physical processes, etc., can solve the problems of difficulty in separation from water, secondary pollution, poor settling performance, etc. Fast, self-stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

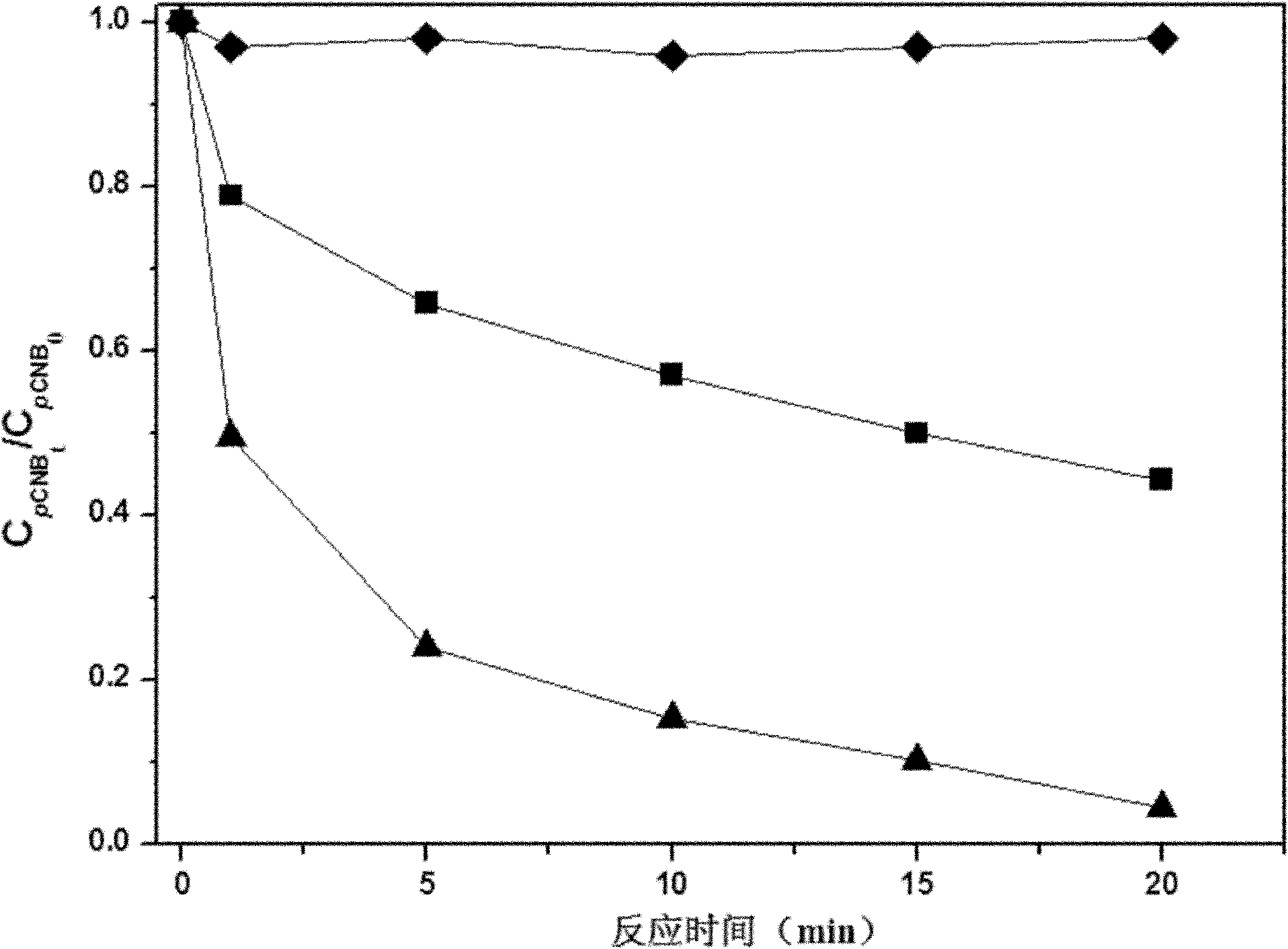

Image

Examples

specific Embodiment approach 1

[0010] Specific embodiment 1: The preparation method of pumice-loaded zinc oxyhydroxide in this embodiment is as follows: 1. Pretreated pumice particles with a particle size of 0.6-0.8 mm are dissolved in a concentration of 0.3 mol / L-3.0 mol / L. Soak in the zinc salt solution for 24 to 48 hours to obtain the mixed solution A; 2. Add the alkaline solution with a concentration of 1.0mol / L to 3.0mol / L dropwise into the mixed solution A, and stir until the solution is no longer Until precipitation occurs, obtain suspension B; 3. Adjust the pH value of suspension B to 12-14, then let it stand for precipitation for 30 minutes, and then activate it at a temperature of 30-60°C for 12-24 hours to obtain a mixture Liquid C; 4. Filter the mixed liquid C to obtain a solid phase, wash the solid phase with distilled water until the pH of the washing liquid is 7.0, and then dry it at a temperature of 30-60°C to obtain pumice-supported hydroxyl oxidation Zinc; wherein the pumice described in s...

specific Embodiment approach 2

[0012] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the pretreatment described in step 1 is to ultrasonically clean the pumice particles with a particle size of 0.6 to 0.8 mm for 2 times, each time for 10 minutes, and then use deionized Rinse with water three times, then dry at 60°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the concentration of the soluble zinc salt solution in step 1 is 2.0 mol / L. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com