Golf putter and counterbalance system and fitting method

a technology of a counterbalance system and a putter, which is applied in the field of golf clubs, can solve the problems that mirrors cannot be used in competition play as sanctioned, and achieve the effects of improving accuracy and repeatability, speeding up the learning process, and improving the player's gam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

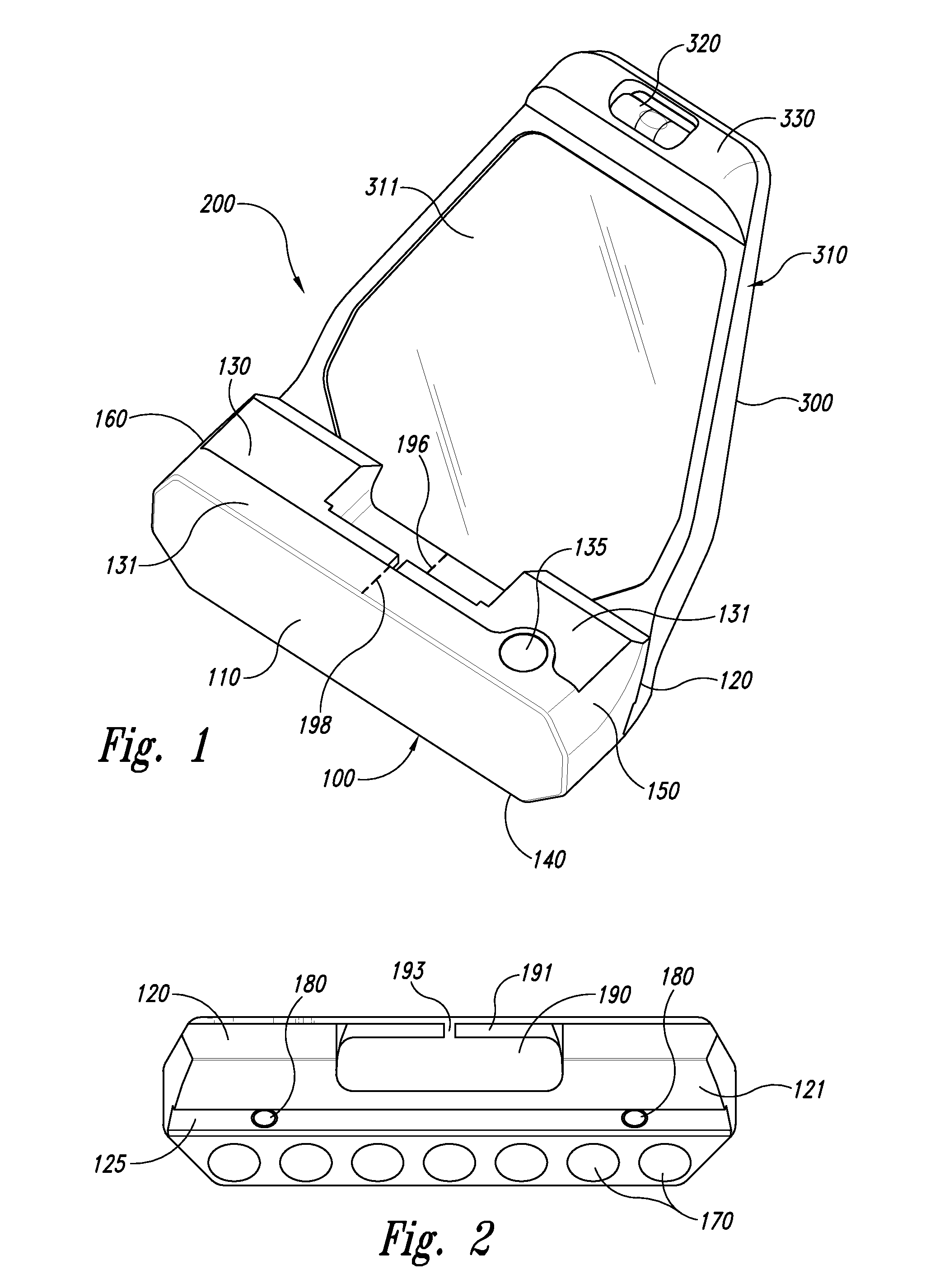

[0085]Referring to FIG. 1, the putter head 100 has golf ball striking face 110, a rearward face 120, a top surface 130, a bottom surface 140, a heel region 150 and a toe region 160. The top of the putter head may comprise a substantially horizontal surface with one or more parallel machined steps 131. The putter head further includes an opening 135 into which a golf club shaft may be inserted.

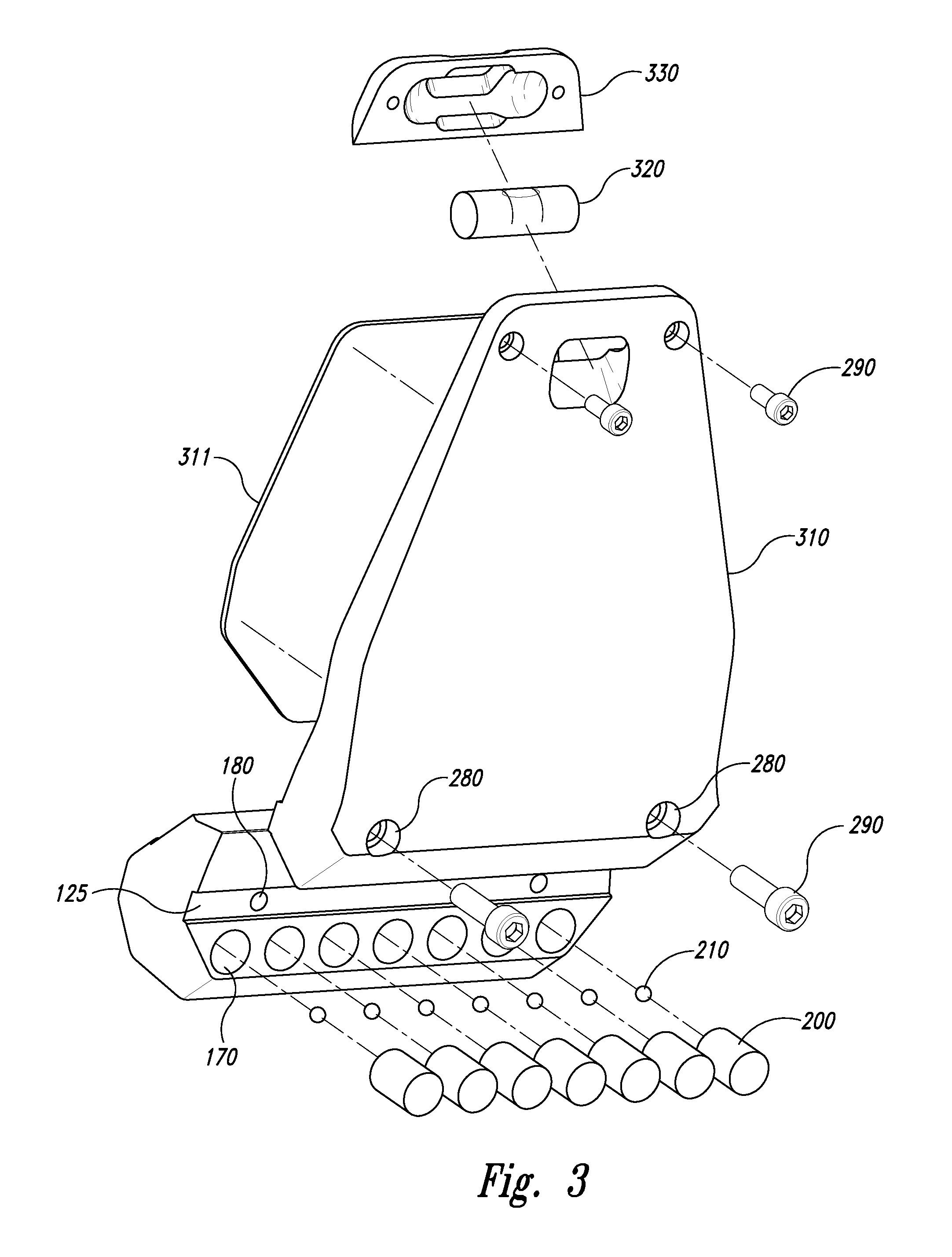

[0086]Referring to FIG. 2, the rearward face 120 has a mounting face 121 with female groove 125 extending across the mounting face in the heel 150 to toe 160 direction. Putter head 100 further comprises bores 170 and threaded apertures 180.

[0087]Referring to FIG. 3, weights 200 are shown. The weights 200 are made from brass, tungsten or steel. Rubber balls 210 are inserted into bores 170 before weights 200 are inserted. Referring to FIG. 4, the weights 200 are retained within bores 170 by mirror attachment 300 when the attachment is fitted to putter head 100.

example 2

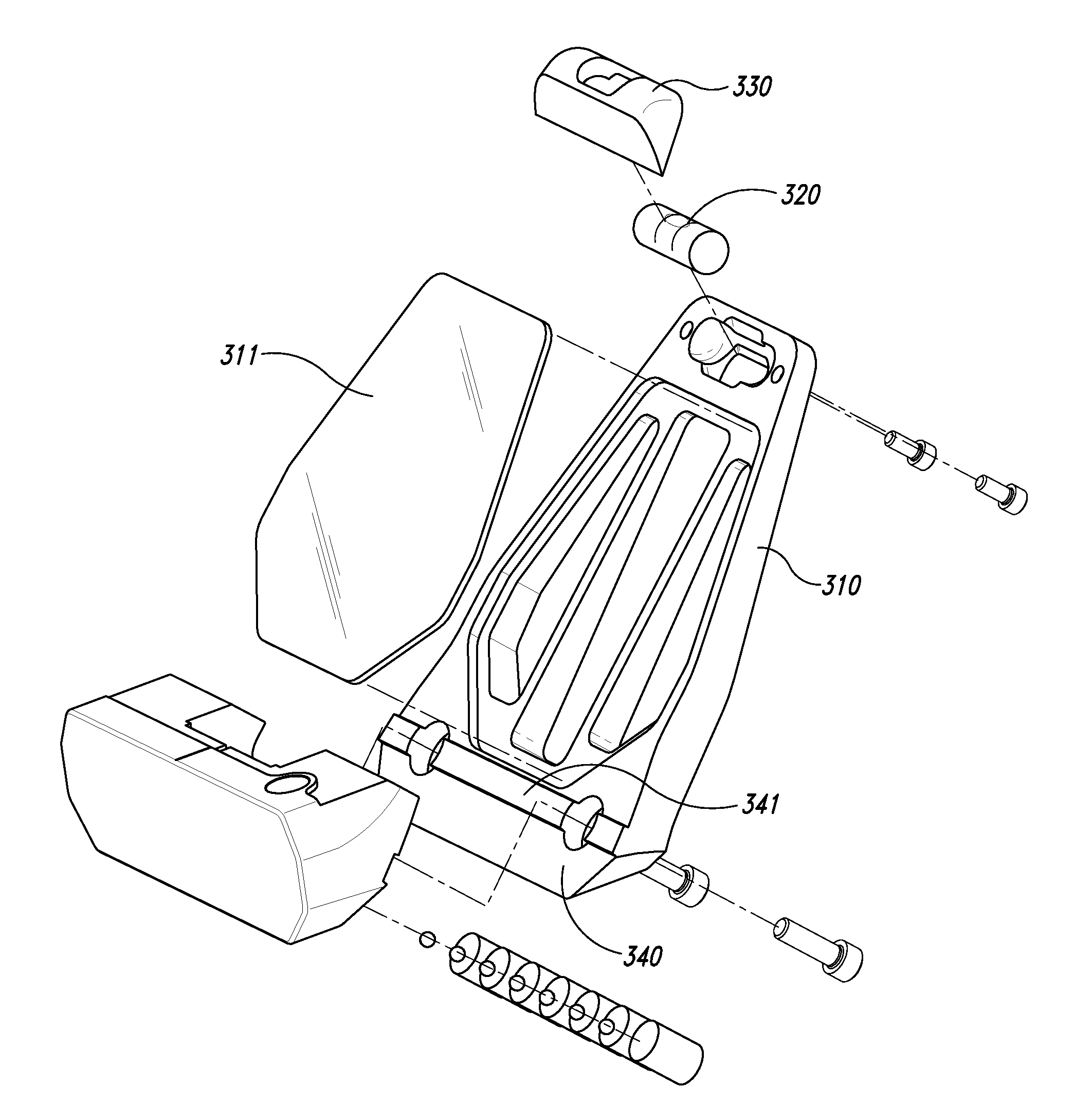

[0088]Referring to FIGS. 1 and 5, the putter head 100 is interconnected to mirror attachment 300. Mirror attachment 300 comprises a frame 310, mirror 311, a bubble level 320, and a removable frame 330 for retaining the bubble level. The frame 310 comprises mounting face 340 with a male feature 341 that matches the female groove 125 of putter head 100. Referring to FIG. 3, apertures 280 match apertures 180 of putter head 100 so that hex-head fasteners 290 can interconnect mirror attachment 300 and putter head 100. Hex head fasteners are also used to attach level frame 330 to mirror frame 310. Apertures 280 are further bored to permit the head of fasteners 290 to recess inside frame 310.

example 3

[0089]Referring to FIGS. 2 and 6, putter head 100 has rear central recess 190. Rear central recess 190 includes a vertical surface 191 and a horizontal surface 194. Vertical surface 191 includes a vertical sight alignment notch 193. First sight alignment mark 196 can be seen through vertical sight alignment notch 193. Second alignment mark 198 is also in line with the sight alignment notch 193 and first sight alignment mark 196 when viewed directly overhead with bubble level 320 showing that the golf putter is level. The curvature of corners 199 are selected to frame golf ball 700, which can be viewed by the golfer in mirror 311.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com