Entire closed-loop circulating fluidized bed as well as usage and application method thereof

A closed circuit, fluidized bed technology, applied in the field of circulating fluidized bed, can solve the problems of high operating temperature, long process flow and high processing cost, and achieve the effects of improving effective utilization, shortening process flow, and small surface heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Embodiment 1: Fully closed circuit circulating fluidized bed

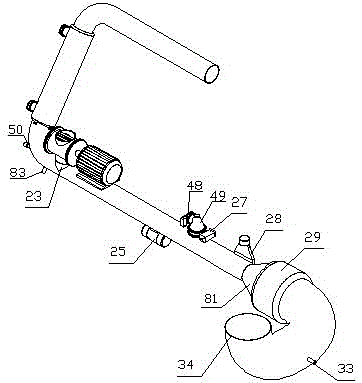

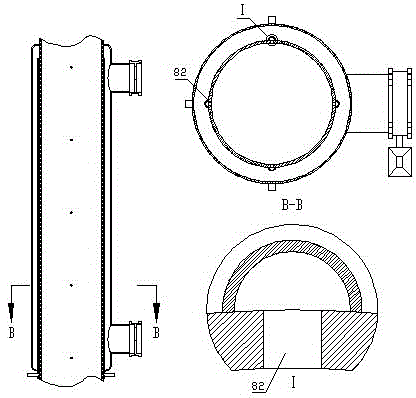

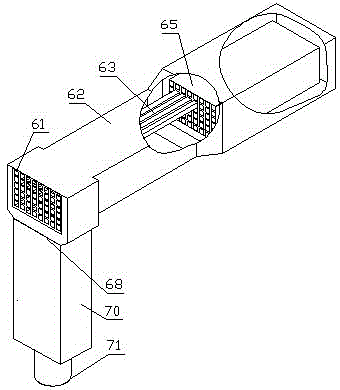

[0106] see figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , a fully closed-circuit circulating fluidized bed, consisting of fan 21, cyclone dust collector 47, dust collector 42, gas treatment branch 38, negative pressure circulation pipe, discharge device and refrigeration equipment; fan 21, cyclone dust collector 47, dust collector 42 and the housing of the dust collector 39 adopt a double-layer structure, and the interlayer space is cooled by the cold air discharged from the condenser; there is a discharge port on the dust discharge pipe 49 of the cyclone dust collector, and a discharge valve 48 is arranged on the discharge port. There is a regulating valve 27 on the outlet of the dust discharge pipe of the cyclone dust collector. The gas treatment branch 38 is used to process the exhaust gas and / or the air intake airflow discharged from the equipment. The gas treatment branch 38 is compose...

Embodiment 2

[0112] Example 2: Another three implementations of the full-closed circulating fluidized bed gas treatment branch

[0113] One of the implementations of the gas processing branch, please refer to the attached Figure 7 , the gas treatment branch is composed of a condenser 106 and a heater 107 connected in sequence, the inlet 105 of the condenser 106 is the air inlet of the gas treatment branch, and the outlet 108 of the heater 107 is the air exhaust of the gas treatment branch;

[0114] For the second embodiment of the gas processing branch, please refer to the attached Figure 8 , the gas processing branch is composed of bypass valve A90, heat exchange pipe A95, shell 93, heat exchange pipe B, condenser, bypass valve C100, heat exchange pipe C96 and heater 99, and the inlet 103 of bypass valve A90 It is the air inlet of the gas processing branch. The inlet and outlet of the bypass valve A90 are provided with heat exchange tube interfaces. The bypass valve A90 has a valve pla...

Embodiment 3

[0119] Embodiment 3: The use method of fully closed-circuit circulating fluidized bed, taking the equipment described in Embodiment 1 as an example, proceed as follows:

[0120] S1. Formulation of operating system: formulate the operating temperature system according to the characteristics of the processed materials and process requirements, formulate the operating medium property system according to the characteristics of the processed materials and process requirements, and supply equipment through the operating medium supply interface to meet the operating medium property system requirements. medium;

[0121] S2. Equipment start-up: start the equipment, adjust the speed of the fan so that the working current of the fan is 40-90% of the rated current;

[0122] S3. Operation process:

[0123] S301. Feeding: Add the pre-processed materials that meet the requirements into the equipment at a constant speed through the feeding device, and stop feeding when the working current of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com