Helmet suspension system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

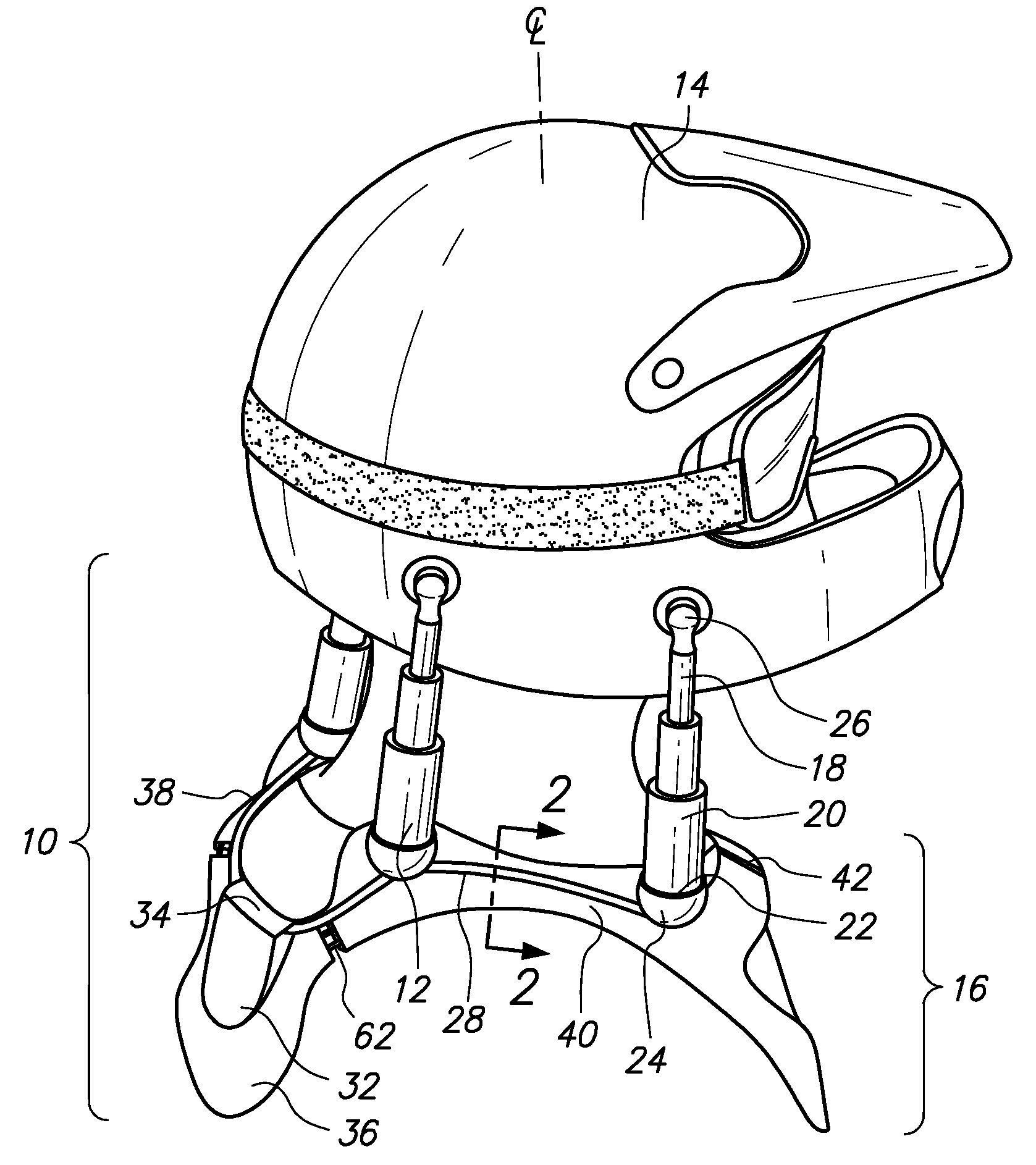

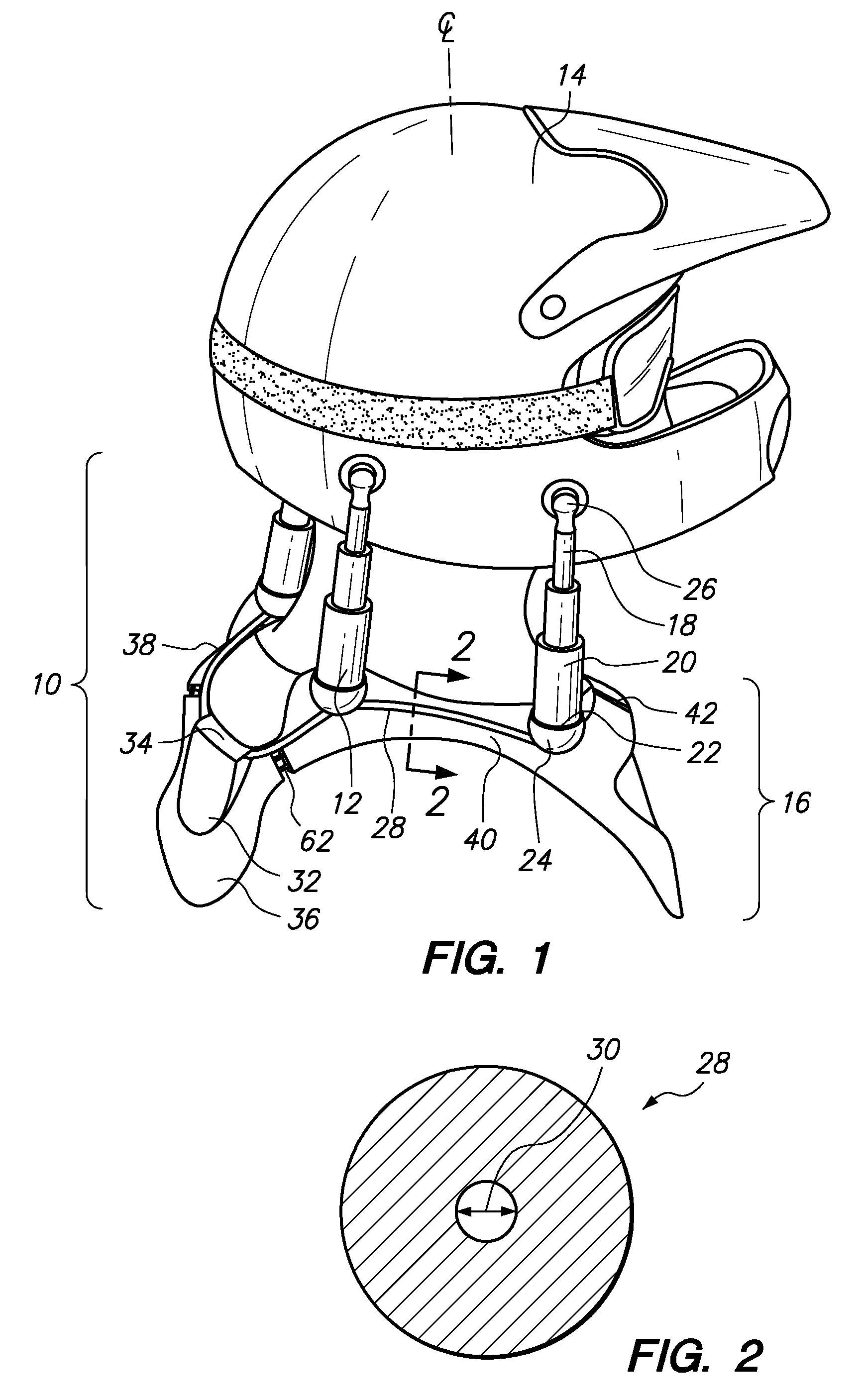

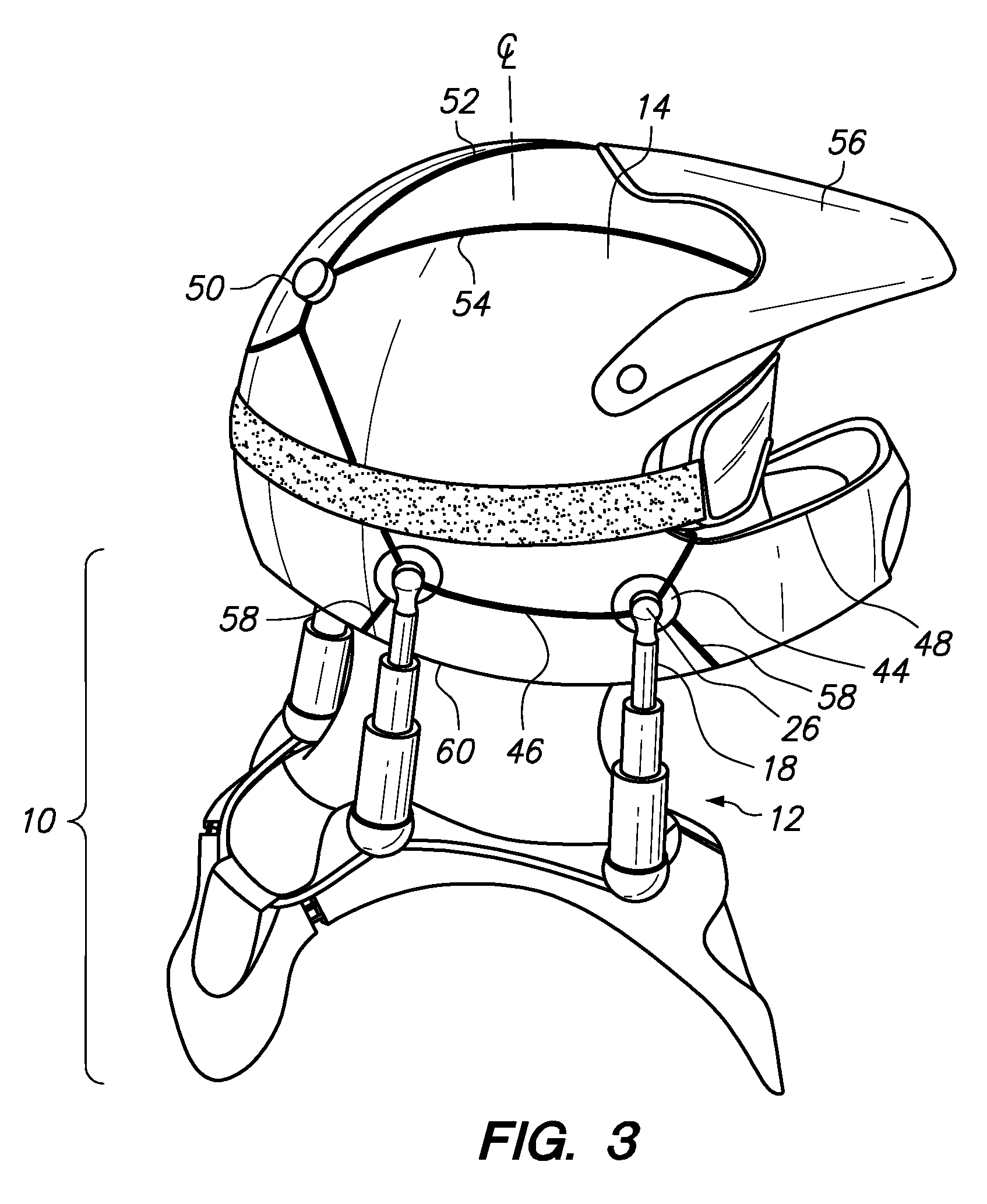

[0015]Referring now to the drawings, FIG. 1 is a rear perspective view of a first embodiment of the helmet suspension system 10. The helmet suspension system 10 may incorporate at least one piston or ram 12. Preferably, the helmet suspension system 10 may include four pistons 12, as shown in FIG. 1. The first piston 12 may be located in the front right area of the wearer. The second piston 12 may be located at the rear right area of the wearer. The third piston 12 may be located at the left rear area of the wearer. Lastly, the forth piston 12 (not shown) may be located around the front left area of the wearer. These pistons 12 limit movement of the helmet 14 upon experiencing extreme high velocity differential between the head and body of the wearer. However, during normal usage, the pistons 12 permit the wearer to rotate his / her head to engage in an activity (e.g., skiing, snowboarding, motocross, racecar driving, cycling, etc.). By way of example and not limitation, in motocross r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com