Storage container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

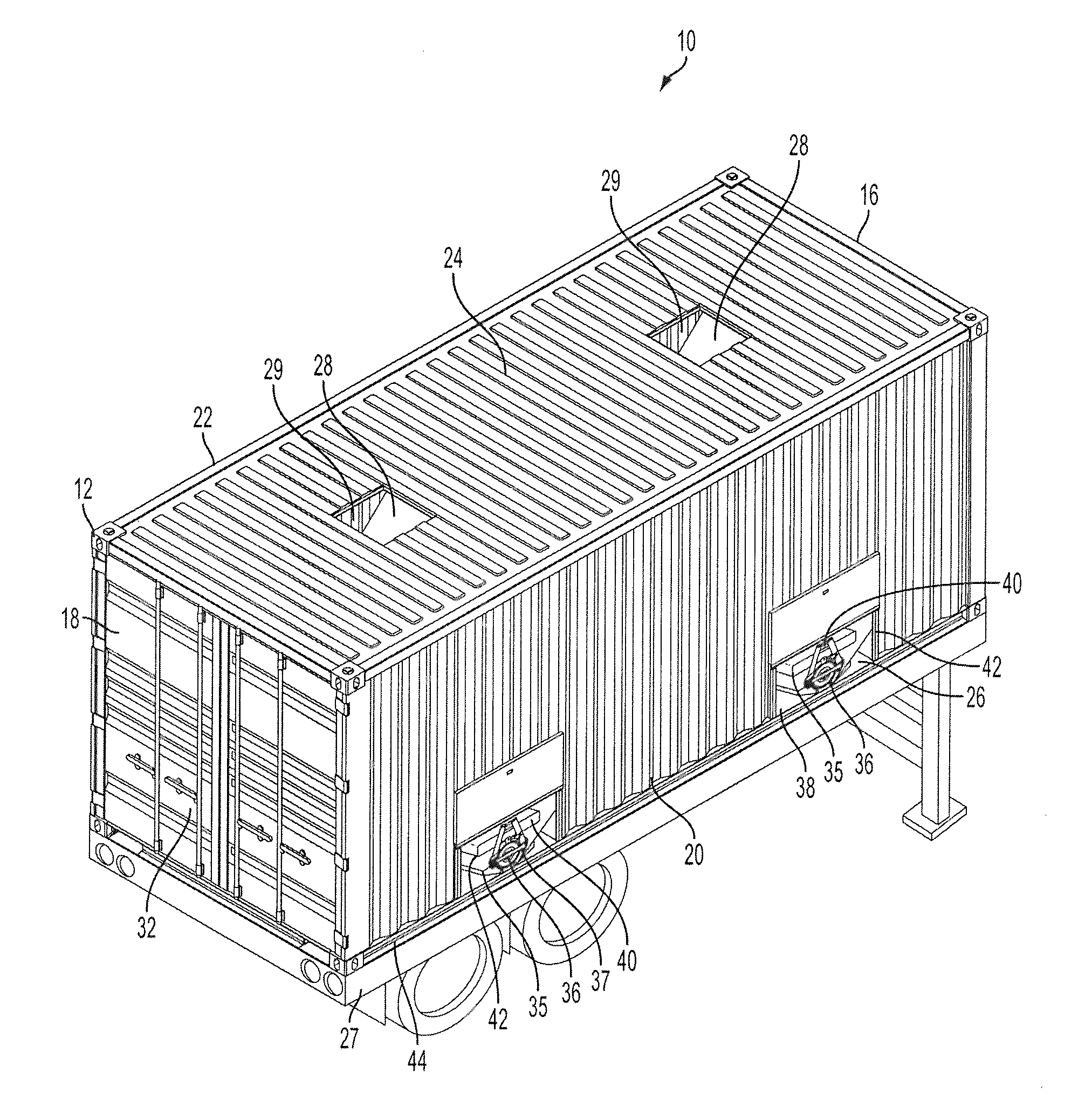

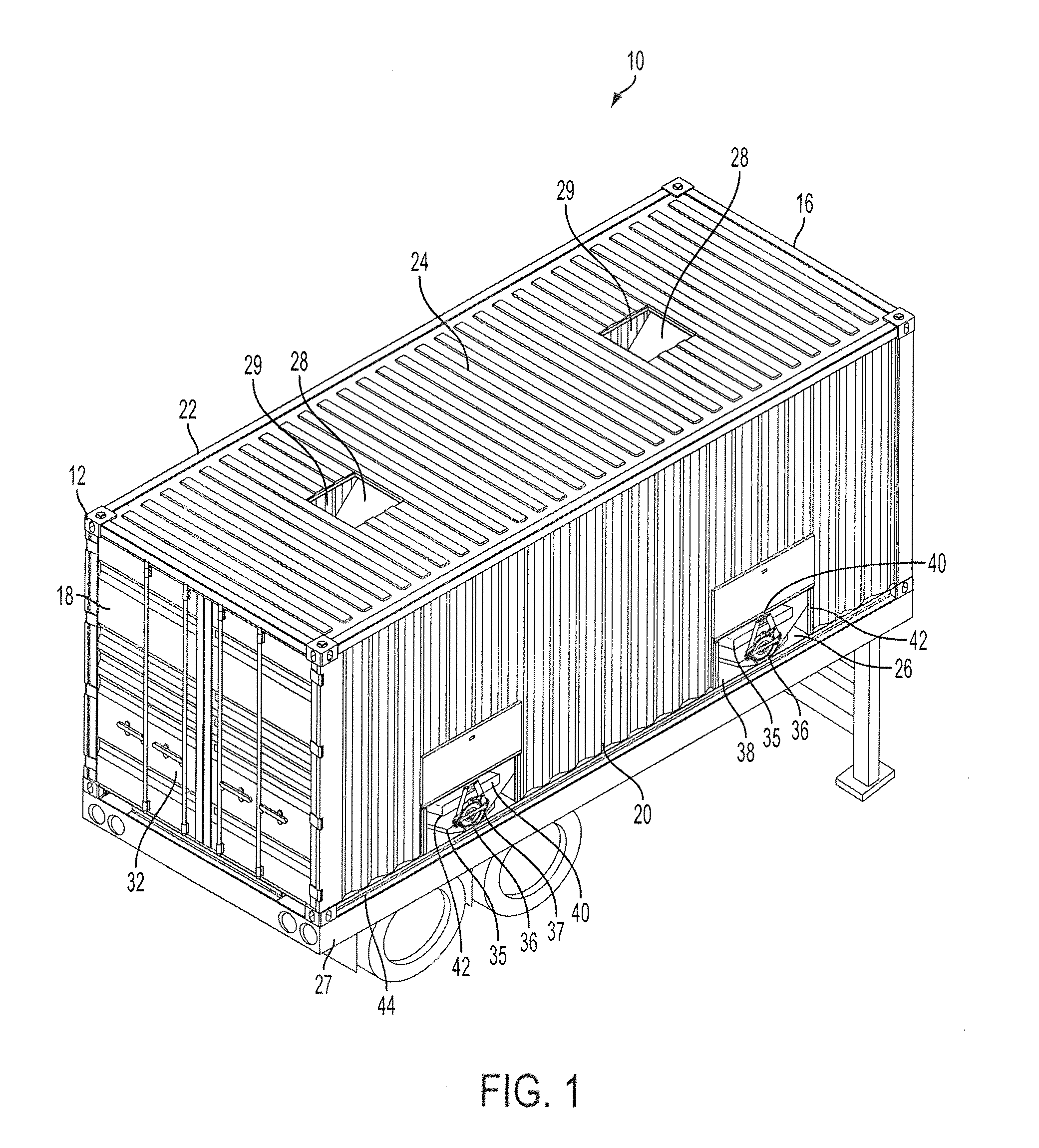

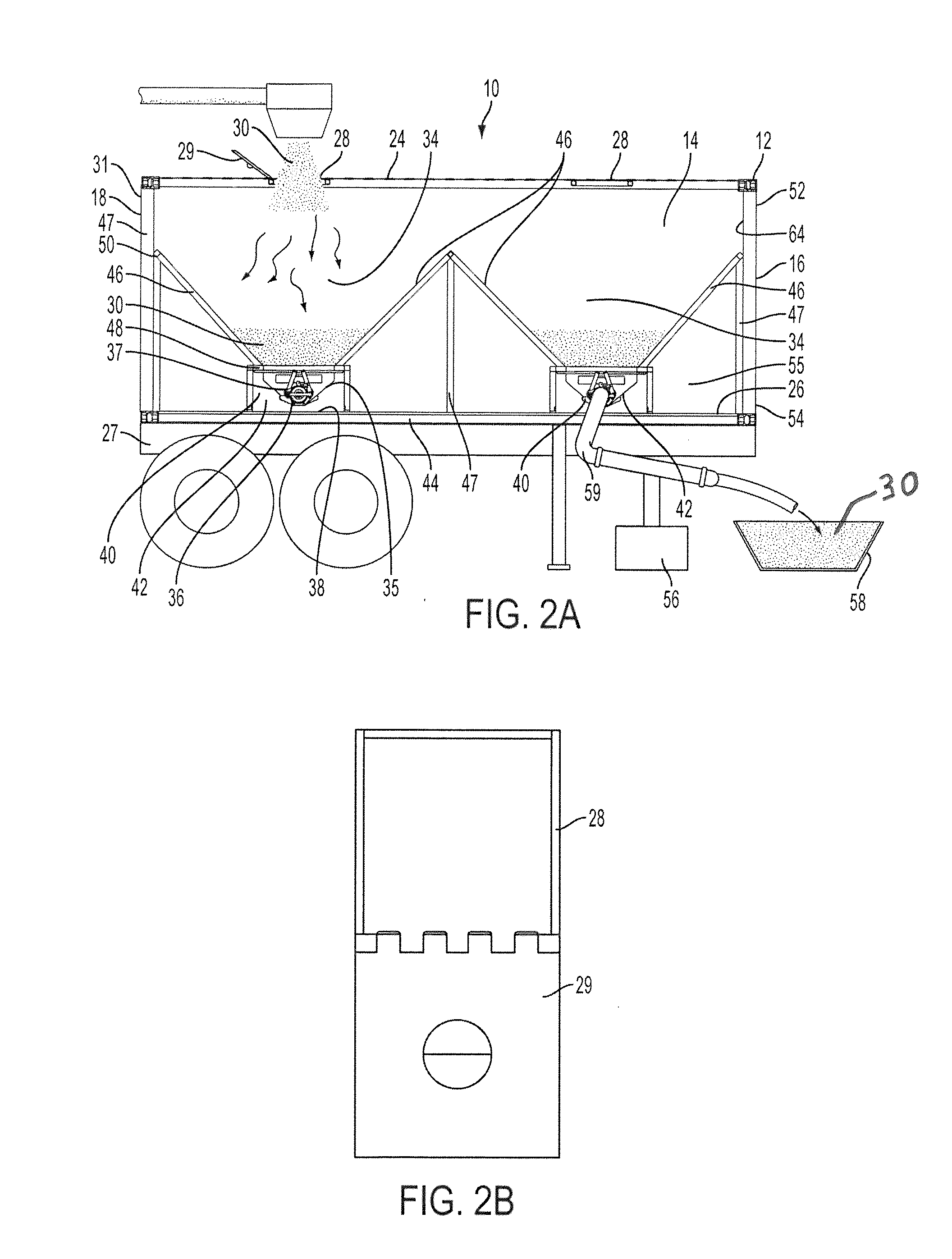

[0022]Referring now to FIGS. 1 and 2, a container is generally designated as 10 and includes a frame 12. A storage cavity 14 is defined by opposing front 16 and back walls 18, opposing side walls 20, 22, a top wall 24, and a floor 26. Each of the front 16 and back 18 walls, side walls 20, 22, top wall 24 and floor 26 connect to the frame 12. The example container 10 generally includes walls 16-24 and floor 26 that are coextensive with the frame 12. Some other embodiments may include one or more walls 6-24 and floor 26 that are not coextensive with the frame 12. The walls 16-24, floor 26, and frame 12 may be constructed as desired, but in many applications a useful balance between strength, weight and durability is desirable. In many applications, the frame is constructed of steel of sufficient gauge, with walls 6-24 and floor 26 likewise constructed of steel. They can be attached to the frame 12 by welding, fasteners or other suitable connection means.

[0023]Although dimensions may b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com