Disassembly and cleaning method of the old belt of the transfer tower bucket elevator

The technology of a bucket elevator and a cleaning method is applied in the directions of cleaning devices, conveyors, conveyor objects, etc., which can solve the problems of slow cleaning progress, repeated labor, low cleaning efficiency, etc., and achieves low operation difficulty and implementation workload. Small, stable feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

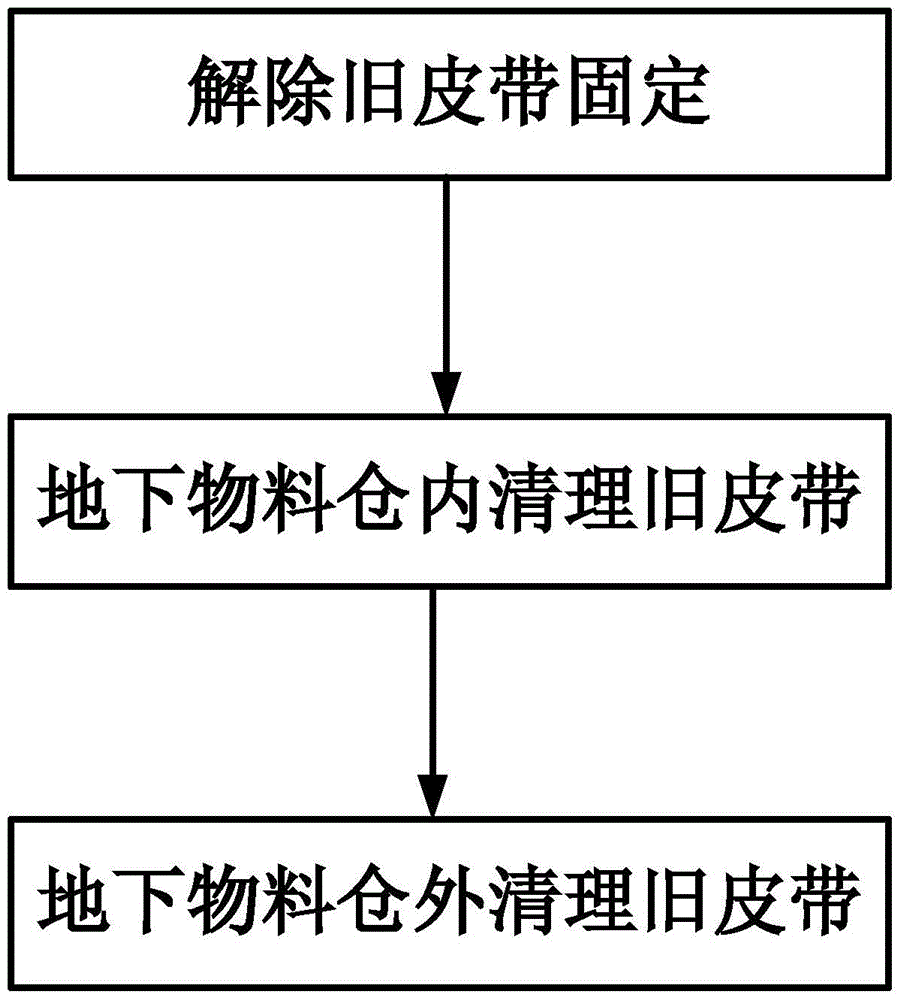

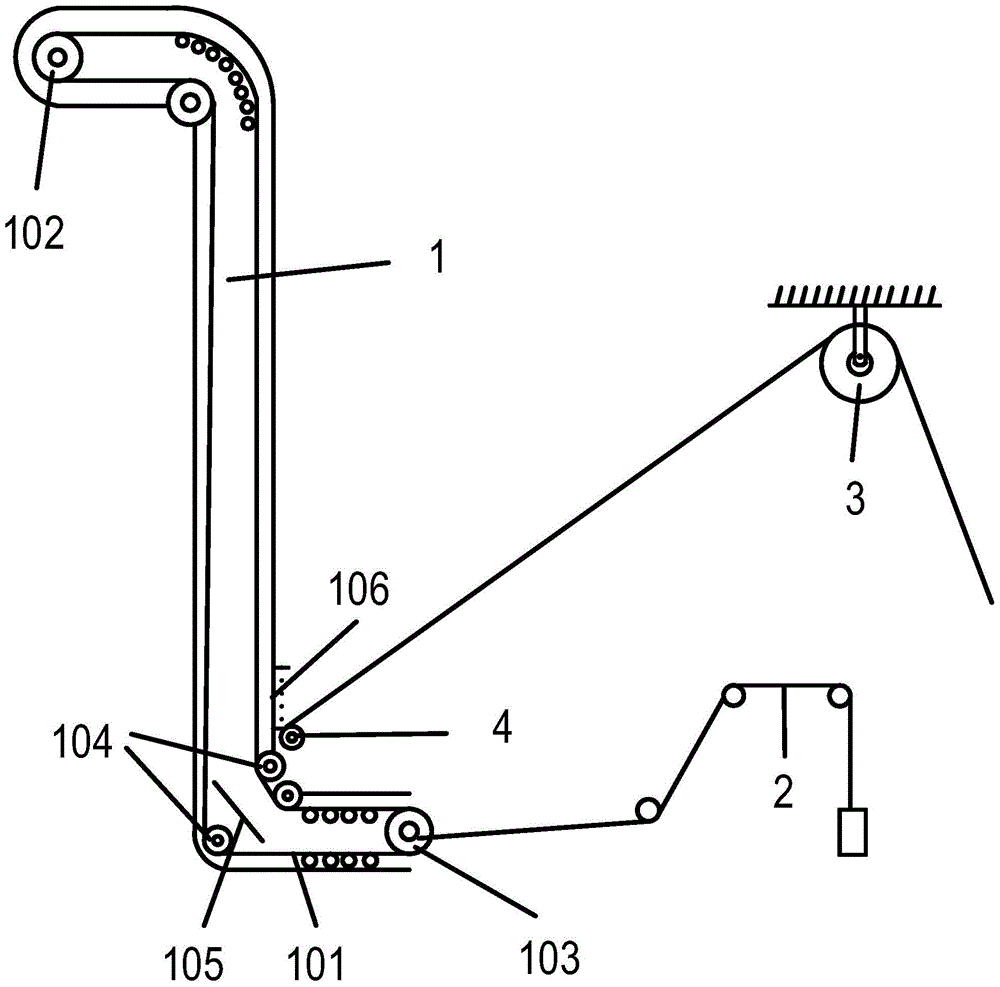

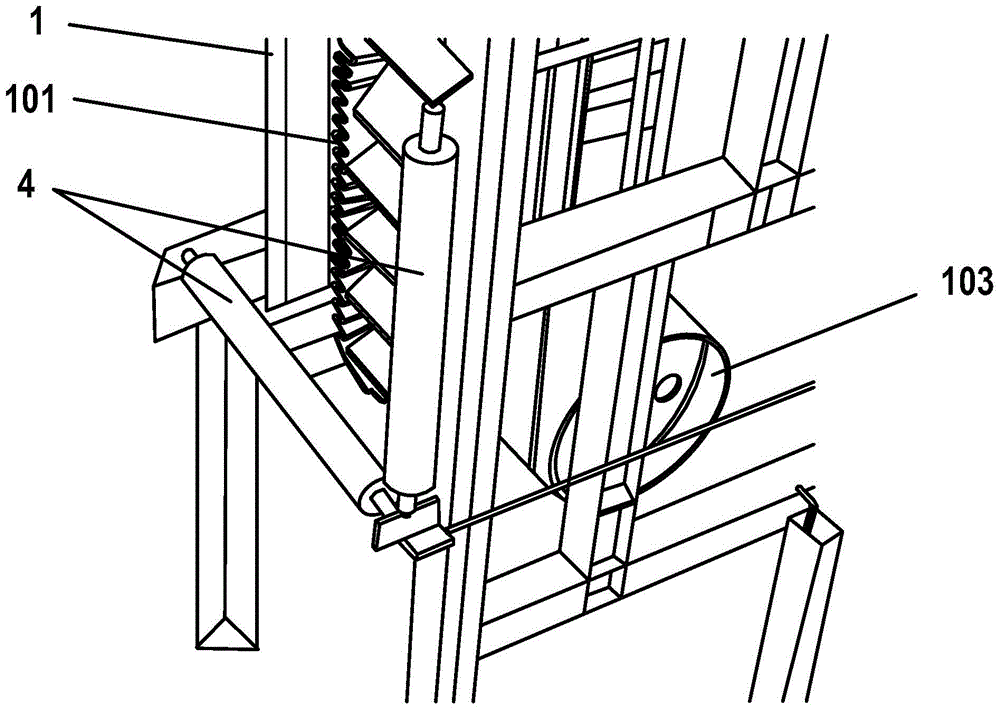

[0038] Such as figure 1 shown, also refer to figure 2 , image 3 , Figure 4 , Figure 5 As shown, the old belt dismounting and cleaning method of the transfer tower bucket elevator of the present invention comprises the following steps:

[0039] Step 1, unfix the old belt: install the first hoisting device 2 in the underground material bin near the tail wheel 103, pull up the weight at the tail wheel 103 through the first hoisting device 2, and let the tail wheel 103 loosen, Remove the concave arc sweeper 105 above the concave arc redirecting drum 104; cut off the old belt 101 with a cutting tool on the concave arc redirecting drum 104 near the tail inspection door 106 side;

[0040] When implemented, such as figure 2 As shown, a chain hoist is used as the first hoisting device 2, of course, an electric hoist can also be used as the first hois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com