Transfer liquid adding device, automatic liquid adding device, 3D printer and liquid adding method

A 3D printer and dosing device technology, applied in 3D object support structure, additive manufacturing, additive processing, etc., can solve the problems of step change, inability to stably control the flow rate of feeding, and achieve the effect of stable feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

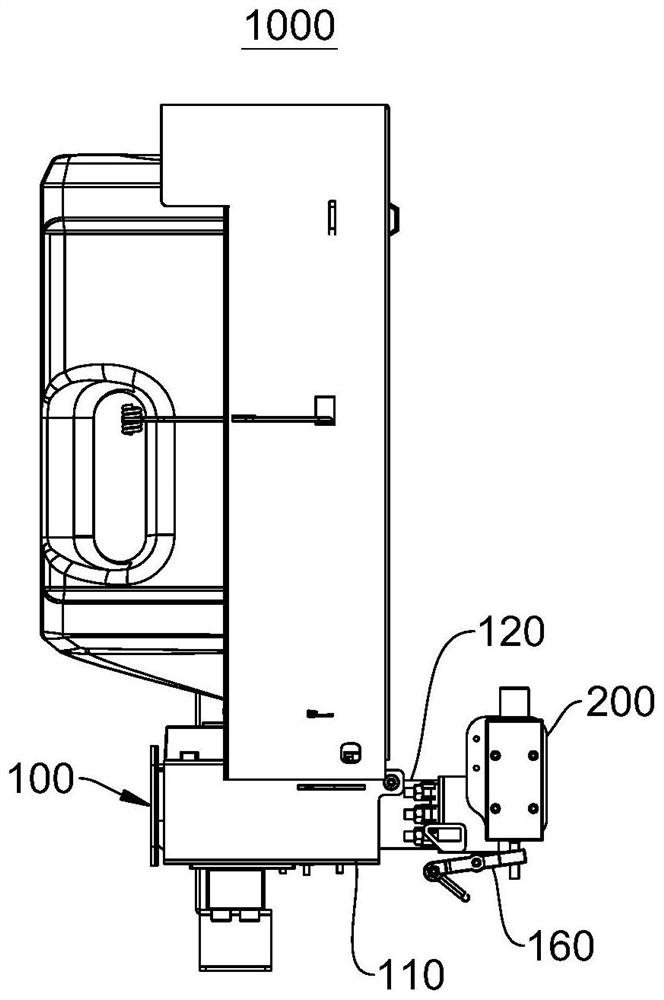

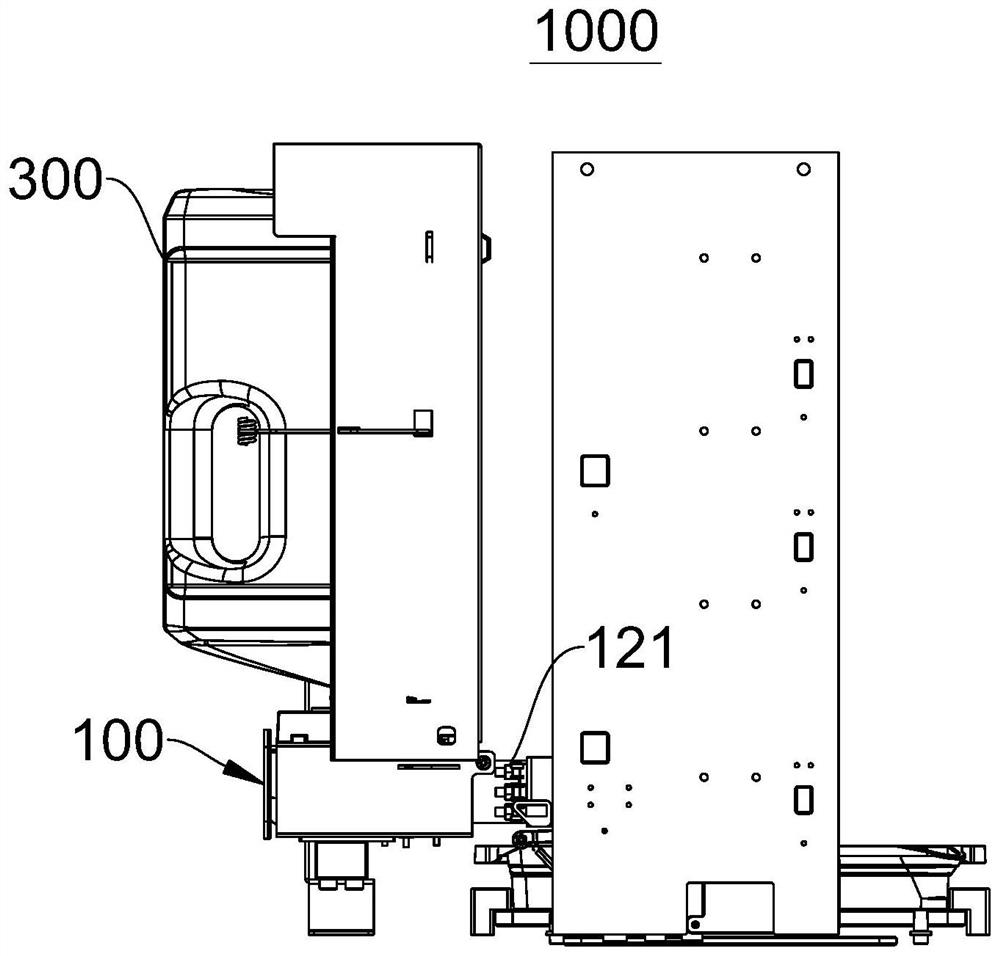

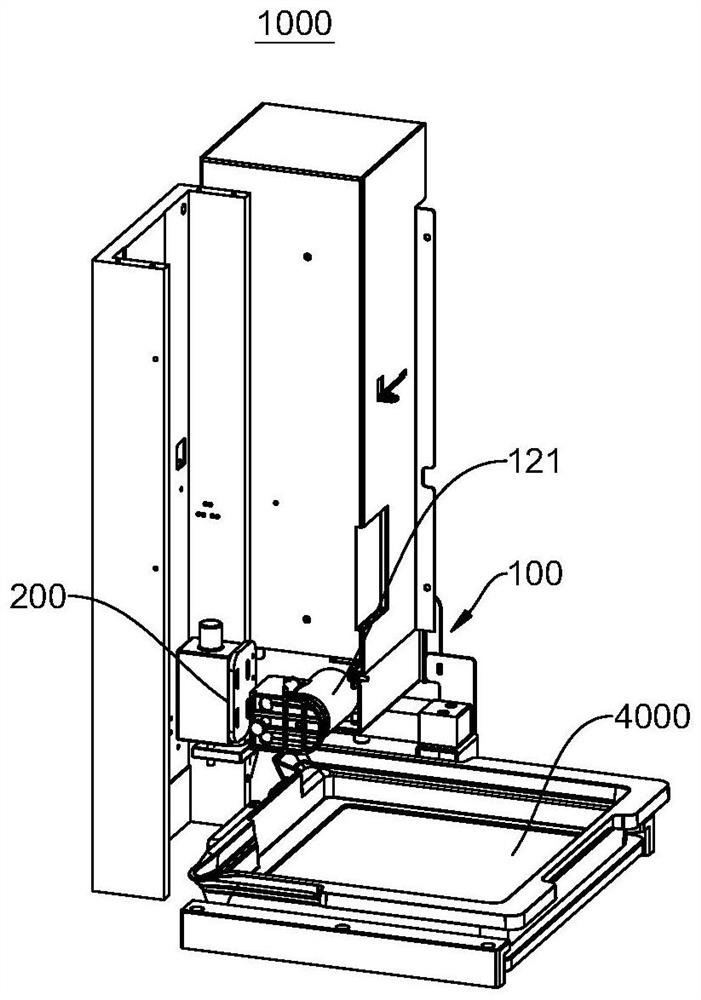

[0085] Please refer to Figure 1-Figure 3 , this embodiment provides an automatic liquid addition device 1000 , and the automatic liquid addition device 1000 includes a relay liquid addition device 100 and a drive device 200 .

[0086] Please refer to Figure 4-Figure 6 , the transfer liquid feeding device 100 includes a feeding box 110 and a locking structure 130. The feeding box 110 includes a feeding box body 115 and a liquid outlet 120 for adding liquid to the feeding tray 4000. The liquid outlet 120 and the feeding box body 115 The feeding box body 115 is used to store the printing material poured by the liquid feeding mechanism, and the printing material stored in the feeding box body 115 can flow to the feeding tray 4000 through the liquid outlet 120 . The locking structure 130 is used to open or block the liquid outlet of the liquid outlet 120 , and the driving device 200 can drive the locking structure 130 to open or block the liquid outlet 120 according to the actua...

no. 2 example

[0128] Please refer to Figure 15-Figure 19 , the embodiment of the present invention also provides a liquid addition method, which is applied to the above-mentioned automatic liquid addition device 1000 or 3D printer 10000. The liquid addition method includes:

[0129] S10, obtain the liquid level information of the material tray of the 3D printer;

[0130] S20, controlling the driving device to drive the blocking member according to the liquid level information.

[0131] In a specific embodiment, the liquid level information includes an initial liquid level;

[0132] According to the liquid level information, the step of controlling the driving device to drive the blocking member includes:

[0133] S200:

[0134] Get the printing model information of the 3D printer;

[0135] Specifically, the printing model information may include parameters of the model, such as the number of printing layers, printing time, slice data, process parameters, and the like. The printing mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com