Air drying machine for pre-processing raw materials in rice oil preparation

An air dryer and pretreatment technology, applied in the direction of dryer, drying, drying solid materials, etc., can solve the problems of unshaped granulation, poor quality, inactivation of rice oil, etc., so as to avoid vibration imbalance and ensure feeding speed, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

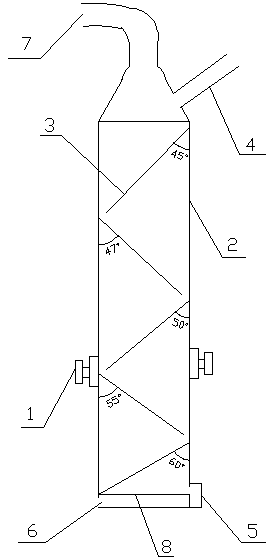

[0013] In order to make the technical scheme of the present invention clearer, the following in conjunction with the attached figure 1 The present invention is described further with embodiment.

[0014] Depend on figure 1 It can be seen that an air dryer for raw material pretreatment in the preparation of rice oil is characterized in that the air dryer mainly includes an air outlet tube 7, an air drying tube 2, a vibrator 1, and a screen 3, wherein the top of the air drying tube 2 is connected to the air outlet tube 7. There is a material inlet 4 on the side of the air outlet, a material outlet 6 and a positive air inlet 5 at the bottom, a screen 3 is provided in the cylinder of the air drying cylinder 2, and two left and right sides are arranged on the outer wall of the middle section of the air drying cylinder 2. Symmetrical Vibrator 1.

[0015] The cylinder body of the air-drying cylinder 2 described above is provided with five inclined screens 3, and the angles formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com