Paver material conveying system with multiple working condition adaptation modes

A material conveying system and paver technology, which is applied in the direction of mechanical equipment, engine components, valve operation/release devices, etc., can solve the requirements that the asphalt material conveying cannot be realized, the electrical control logic relationship is complicated, and the replacement cannot be reduced. To improve the road surface quality, reduce aggregate segregation, and reduce segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

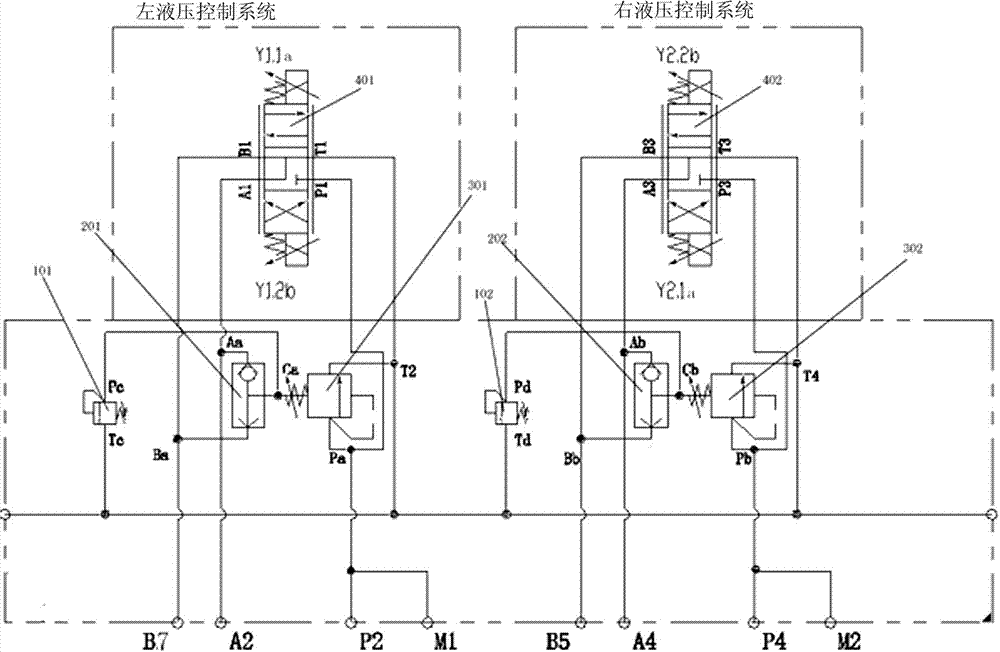

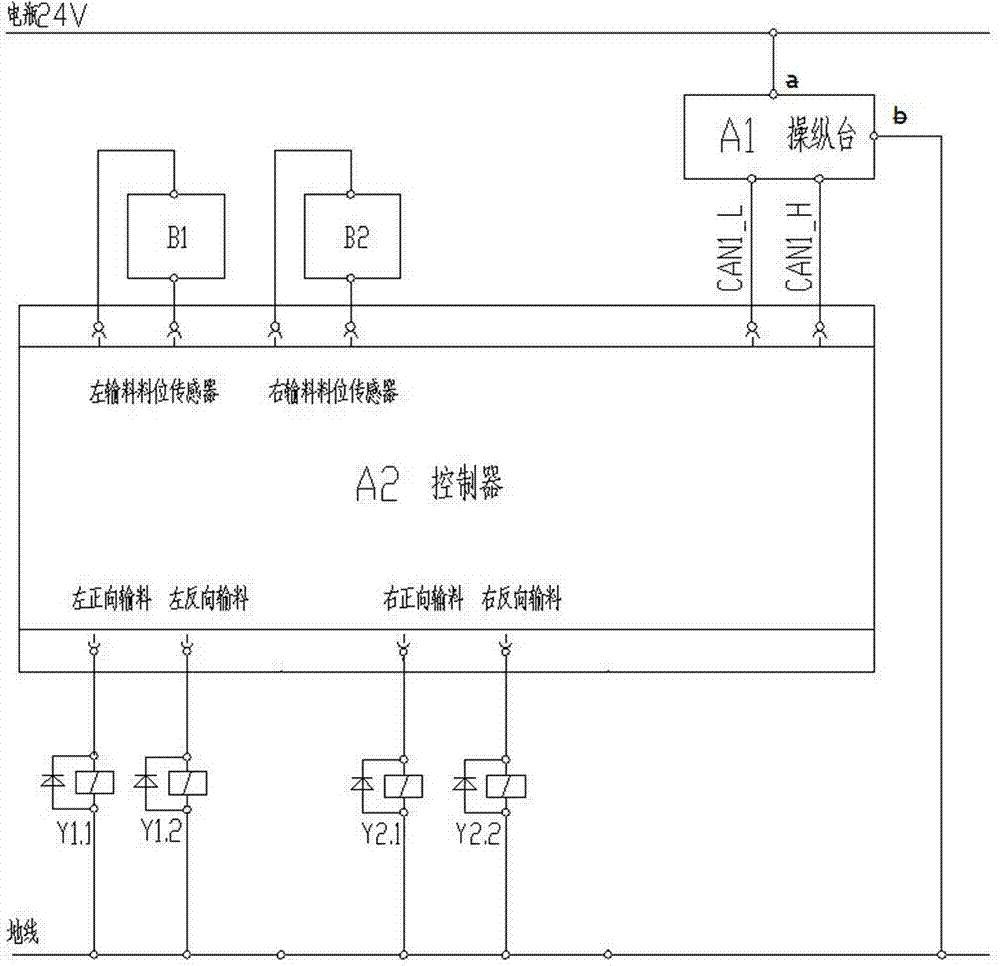

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] The technical solution adopted by the present invention is: the feeding solenoid valve is connected with the proportional solenoid valve, and two control modes are set for different paving materials, that is, when paving stabilized soil materials, the control signal is the maximum / minimum two gears, and the proportional When the valve is used as an on-off valve, it can reduce the segregation of the material by increasing the discharge speed of the material delivery port. When the on-off valve is turned on and reversing, the electrical control adopts a slope control signal to reduce the impact of reversing; when paving asphalt materials, it adopts proportional control to improve The stability of the system. The two working modes are switched by switches, and the control panel is equipped with switches to adapt to different working conditions. When the material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com