Device and method for continuously producing silver powder for solar energy

A technology of solar energy and silver powder is applied in the field of material science to achieve the effects of convenient operation, high purity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

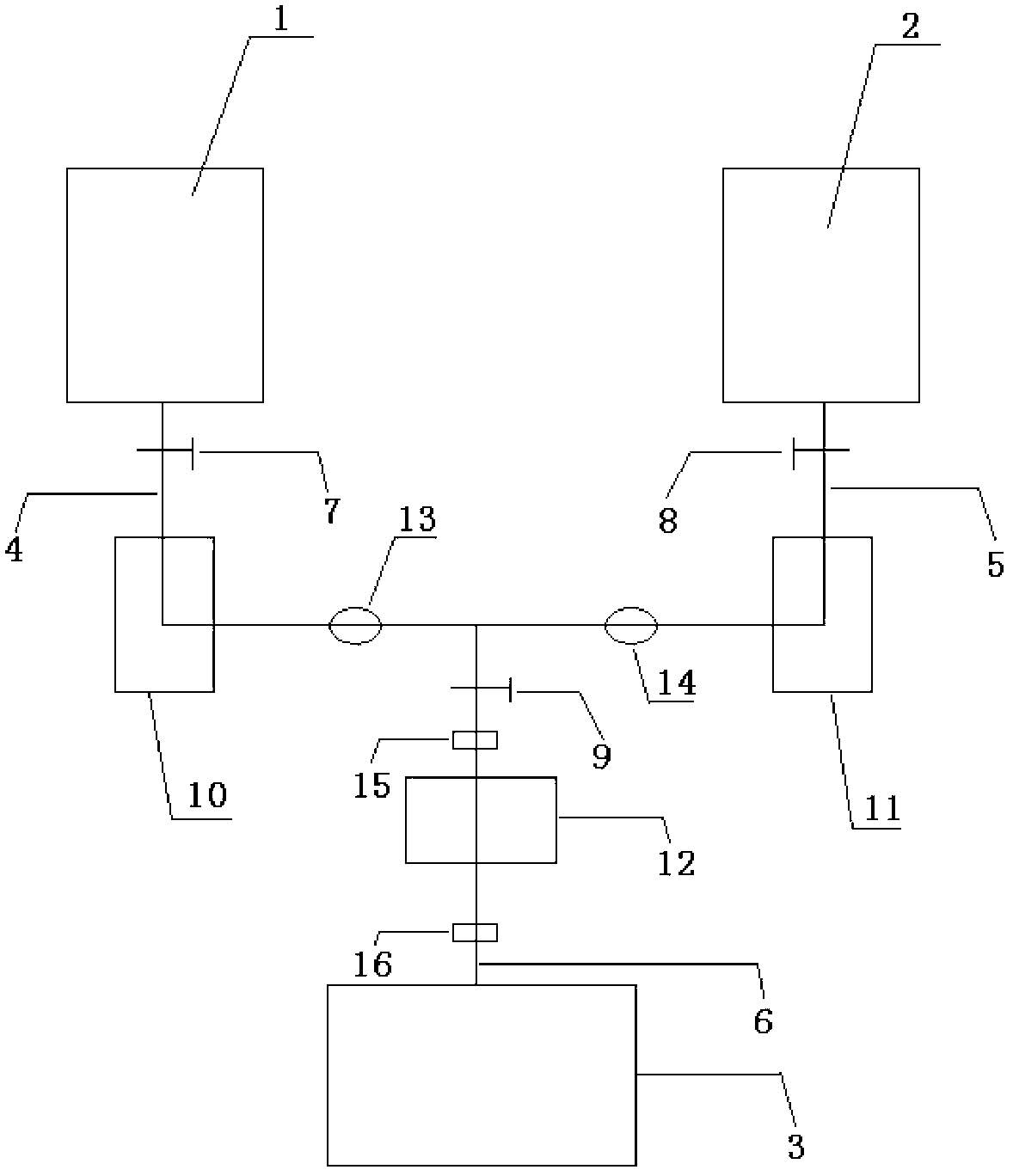

[0023] Device for continuous production of silver powder for solar energy, see figure 1 , including a first liquid distribution tank 1, a second liquid distribution tank 2, and a container 3, the liquid outlet of the first liquid distribution tank 1 is connected with one end of the first pipeline 4, and the outlet of the second liquid distribution tank 2 The liquid port is connected with one end of the second pipeline 5, the liquid inlet of the container 3 is connected with one end of the third pipeline 6, the other end of the first pipeline 4, the second pipeline 5 and the third pipeline 6 are connected, and the first pipeline A pipeline 4 is provided with a first solenoid valve 7, a first water bath device 10 and a first flow meter 13, and the second pipeline 5 is provided with a second solenoid valve 8, a second water bath device 11 and a second flow meter 14 , the third pipeline 6 is provided with a third solenoid valve 9 and a third water bath device 12 in sequence. It a...

Embodiment 2

[0025] Utilize the device described in embodiment 1 to continuously produce silver powder for solar energy, the steps are as follows:

[0026] (1) Configure the hydrazine hydrate polyvinylpyrrolidone aqueous solution in the first liquid mixing tank, wherein the concentration of hydrazine hydrate is 7g / L, the concentration of polyvinylpyrrolidone is 0.2g / L, and adjust the temperature of the hydrazine hydrate polyvinylpyrrolidone aqueous solution to 10°C;

[0027] (2) Mix silver nitrate polyvinylpyrrolidone aqueous solution in the second liquid mixing tank, wherein the concentration of silver nitrate is 50g / L, the concentration of polyvinylpyrrolidone is 1.5g / L, adjust the pH to 8 with ammonia water, and adjust the hydration Hydrazine polyvinylpyrrolidone aqueous solution temperature to 10 ° C;

[0028] (3) Control the temperature of the first water bath device, the second water bath device and the third water bath device to 10°C, open the first solenoid valve, the second solen...

Embodiment 3

[0031] Utilize the device described in embodiment 1 to continuously produce silver powder for solar energy, the steps are as follows:

[0032] (1) Configure the hydrazine hydrate polyvinylpyrrolidone aqueous solution in the first liquid mixing tank, wherein the concentration of hydrazine hydrate is 28g / L, the concentration of polyvinylpyrrolidone is 0.8g / L, and adjust the temperature of the hydrazine hydrate polyvinylpyrrolidone aqueous solution to 25°C;

[0033] (2) Mix silver nitrate polyvinylpyrrolidone aqueous solution in the second liquid mixing tank, wherein the concentration of silver nitrate is 200g / L, the concentration of polyvinylpyrrolidone is 6g / L, adjust the pH to 13 with ammonia water and sodium hydroxide, and Adjust the temperature of the hydrazine hydrate polyvinylpyrrolidone aqueous solution to 25°C;

[0034] (3) Control the temperature of the first water bath device, the second water bath device and the third water bath device to 25°C, open the first solenoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com