Vibration-type measuring sensor for conduction measurements in media flowing inside two medium lines, and in-line measuring device equipped with a measuring sensor of this type

A technology for measuring transmitters and measuring tubes, applied in the direction of measuring flow/mass flow, direct mass flow meters, measuring devices, etc., can solve problems such as increased technical complexity, and achieve low cost, high measurement accuracy, and high zero point stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

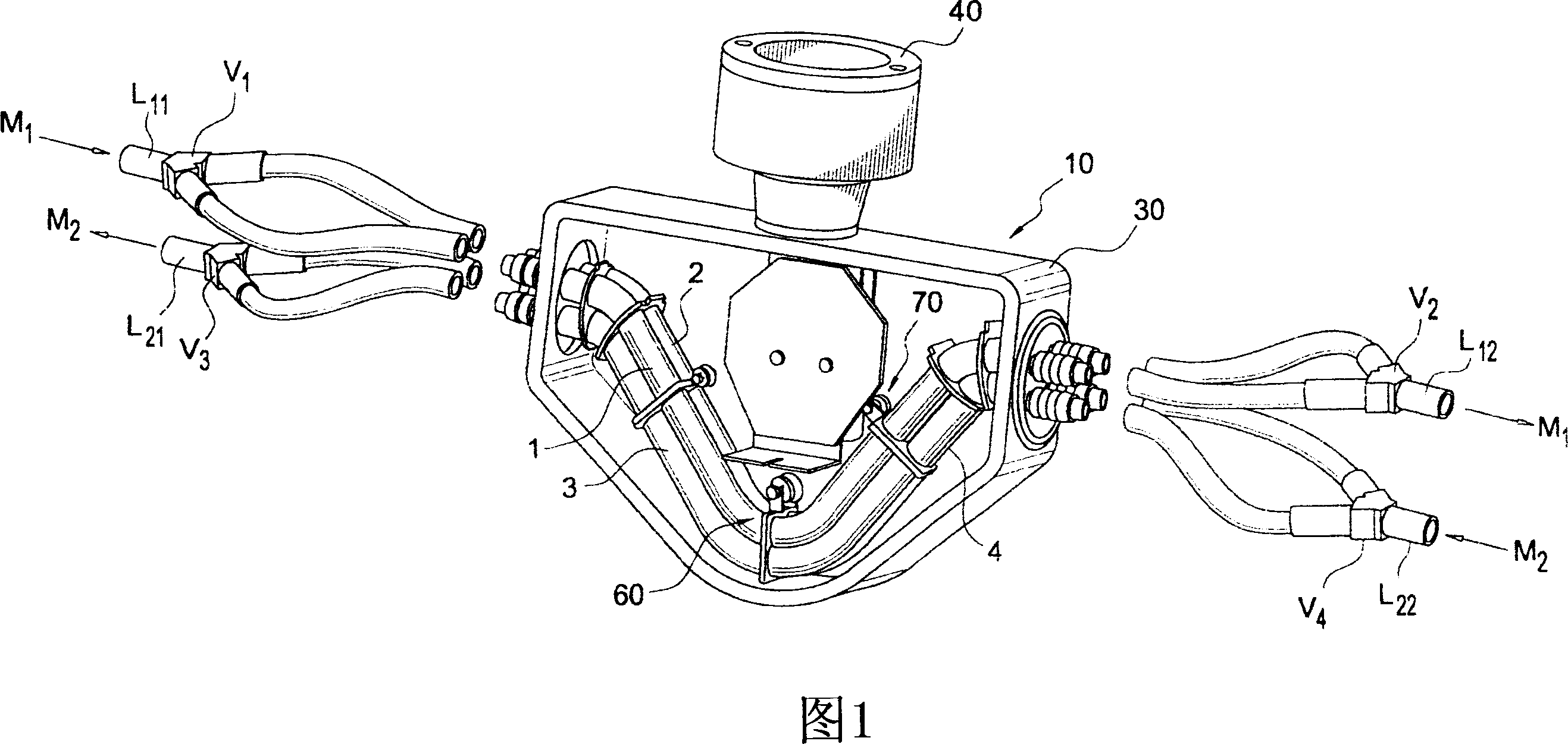

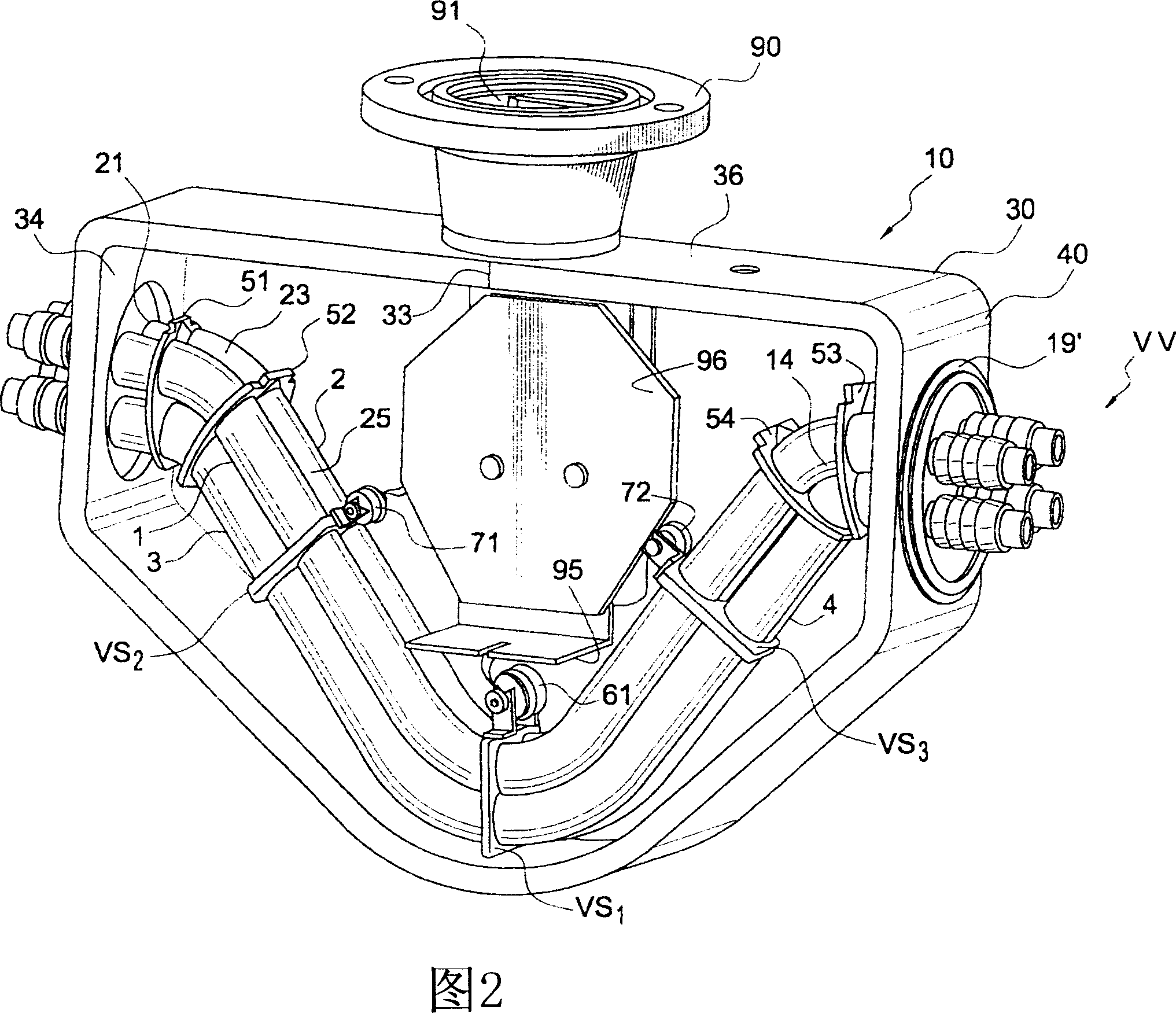

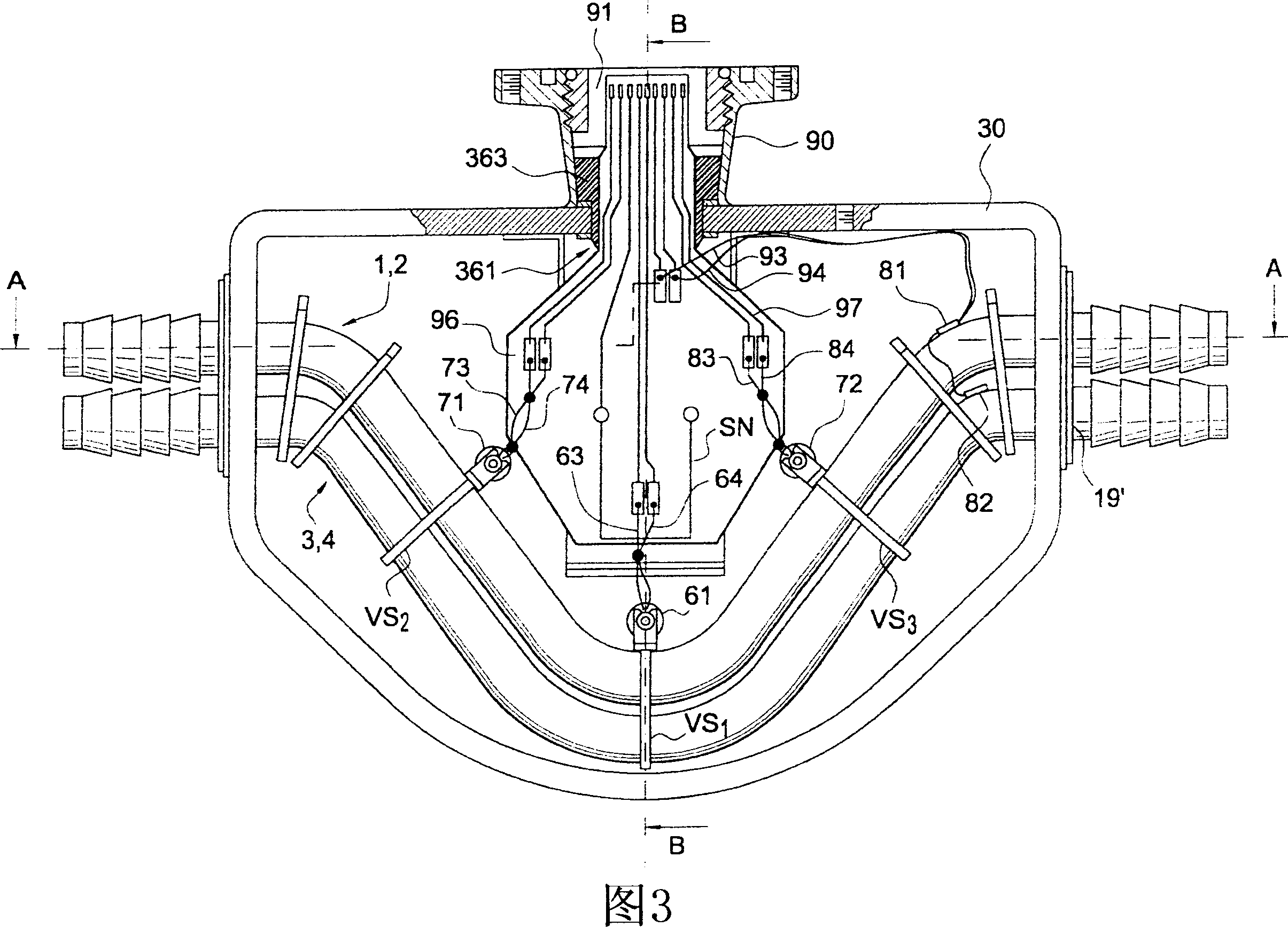

[0055] FIG. 1 shows an in-line measuring device for the in particular simultaneous measurement of two media conveyed separately from one another. For this purpose, the in-line measuring device includes a physical-electronic measuring transducer, which is accommodated in a first mounting system 30 , which is formed in particular as a transducer housing. In addition, the in-line measuring device comprises measuring and operating electronics, which are electrically connected to the measuring transmitter 10 , which are housed in particular in the electronics housing 40 . The online measuring instrument is used in particular to determine the first medium M flowing at least temporarily in the first medium pipeline 1 and the second medium M flowing at least temporarily in the second medium conduit 2 The balance between, especially the difference and / or sum of the mass flow rates of the two media, or the average density and / or viscosity of the two media, etc. Medium 1 Can be, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com