Parallel workbench for realizing space three-translation high-frequency excitation

A three-translation, workbench technology, used in vibration testing, machine/structural component testing, measuring devices, etc., can solve the problem of inability to simulate multi-degree-of-freedom high-frequency vibration output, inability to simulate multi-dimensional real vibration, and inability to achieve high-frequency motion output and other issues, to achieve the effect of compact structure, high rigidity of parallel mechanism and high transmission of high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

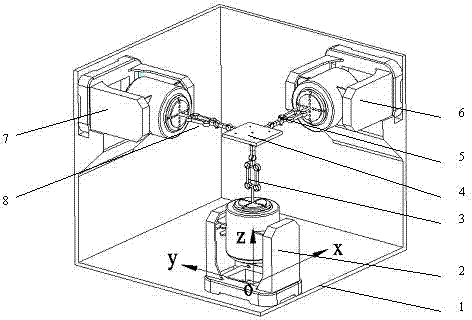

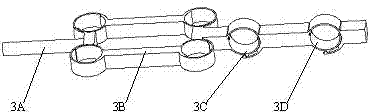

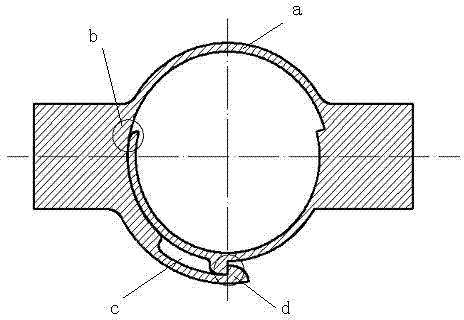

[0018] see figure 1 , the present invention is made up of three parts, one is the moving platform 4 that is used to install the component to be tested, and it can realize the high-frequency vibration of three translations in space; , 7, provide the high-frequency input required by the entire workbench, the third is the three parallel branch chains 3, 5, 8 connecting the moving platform 4 and the single-dimensional vibrator 2, 6, 7, and the three parallel branch chains 3, 5 , 8 are connected with the moving platform 4 in an orthogonal form, and connected with the single-dimensional vibrator at the three drive inputs.

[0019] The static platform 1 is composed of three panels, the three panels are respectively a horizontal bottom panel and two vertical panels, and the two vertical panels are orthogonal to each other and are vertically orthogonal to a horizontal bottom panel. In the space surrounded by three panels, a single-dimensional exciter is fixed vertically on each panel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com