Chain Guards and Chainsaw Systems

A chain cover and chain saw technology, which is applied to sawing equipment, sawing machine devices, sawing components, etc., can solve the problems of the chain cover falling off, the cutting kit being not completely covered, and the lack of clamping force, etc., and achieving the effect of reliable maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

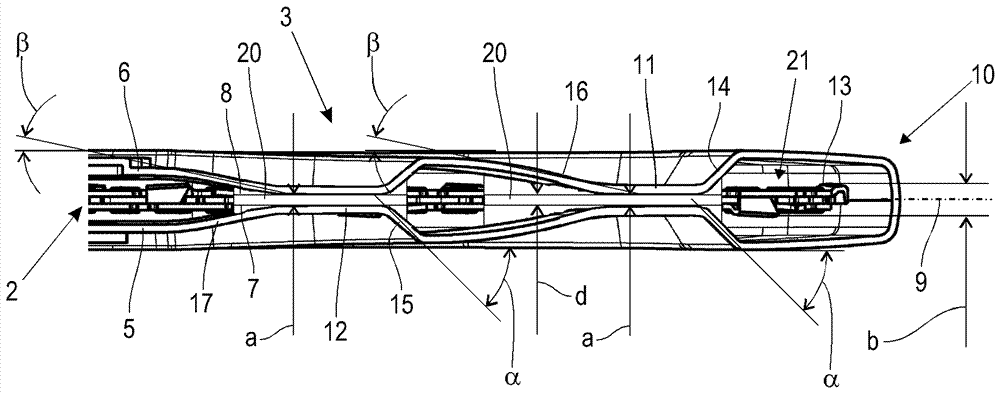

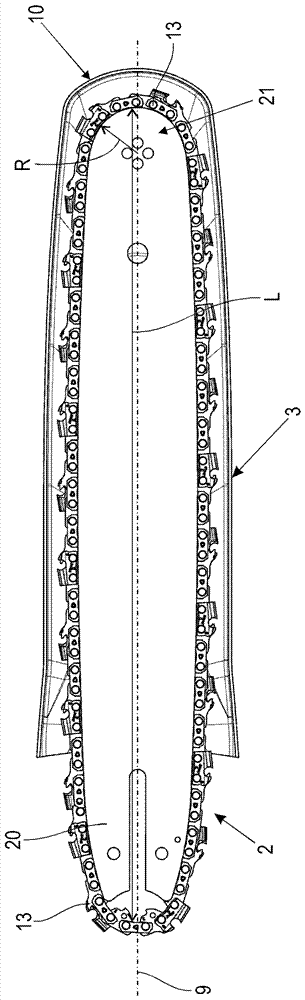

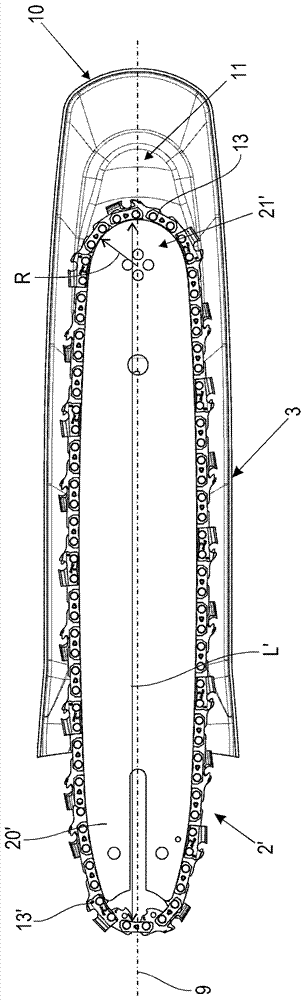

[0029] figure 1 In a perspective view is shown a chainsaw system embodied according to the invention comprising different, replaceable cutting sets 2, 2' with different lengths L, L' (which are in Figure 2 to Figure 8 The chain saw 1 shown in ). Furthermore, the chain saw system has a chain guard 3 which can be pushed onto the corresponding cutting set 2, 2' ( Figure 2 to Figure 8 )superior.

[0030] The chain saw 1 has a motor housing 22 in which a drive motor (not shown in detail) is arranged. Furthermore, a front handle 23 and a rear handle 24 are arranged on the motor housing 22 for guiding the chain saw 1 during sawing.

[0031]The chain guard 3 is designed as a box closed all around made of plastic with a wall thickness of approximately 1.5 mm and has two opposite side walls 5 , 6 and a circumferential peripheral wall 25 on the narrow side. As the only exception to the otherwise overall closed construction, the chain guard 3 is provided on its side facing the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com