Micro-crack nondestructive detection system and detection method thereof

A non-destructive testing and micro-crack technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problem of insignificant changes, and achieve the effects of improving sensitivity, convenient use and high detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

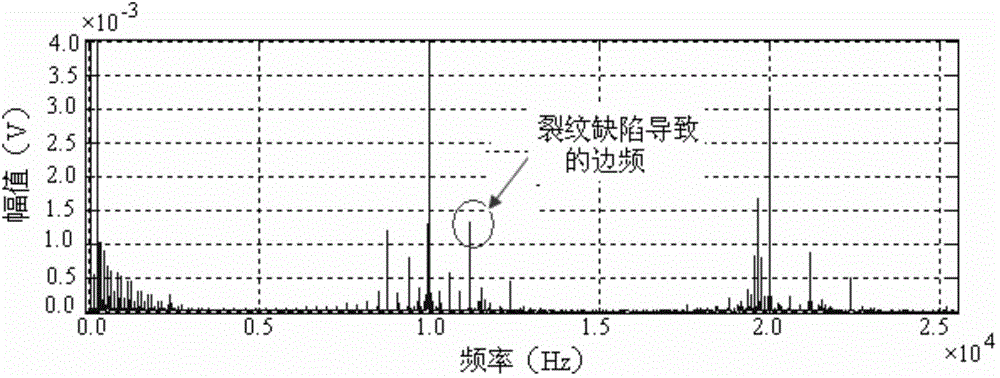

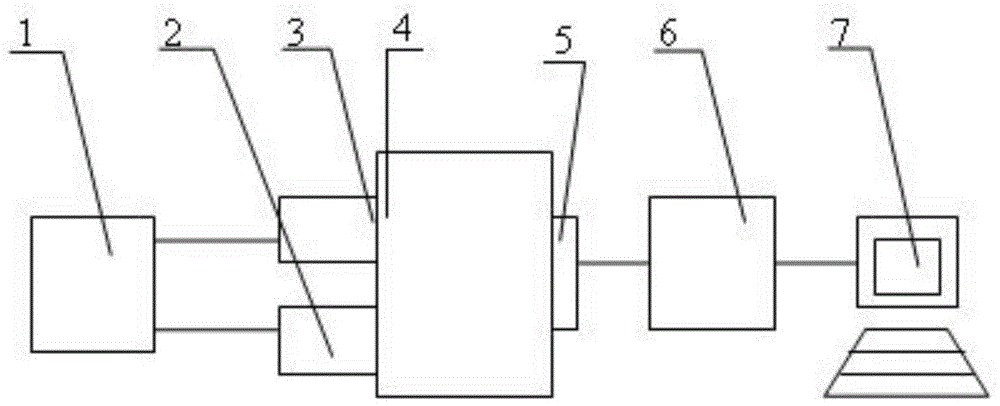

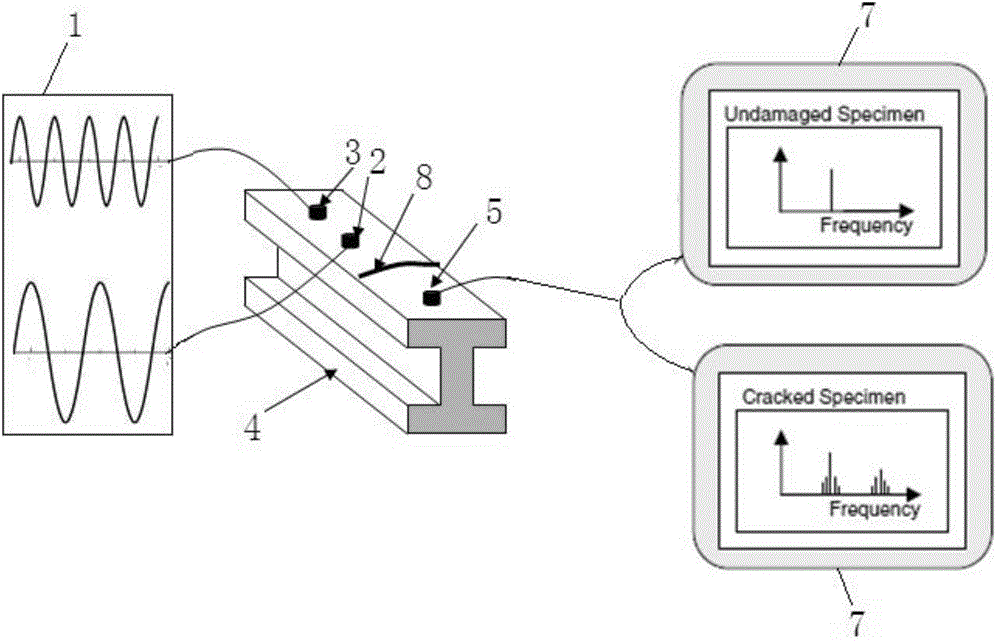

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. see figure 1 , the nondestructive testing system for microcracks of the present invention includes a signal generator 1, a low-frequency exciter 2, a high-frequency exciter 3, a member under test 4, a piezoelectric sensor 5, a preamplifier 6, and a signal acquisition and analysis system 7; the signal generator 1. The low frequency exciter 2 and the high frequency exciter 3 are electrically connected to the measured component 4. The piezoelectric sensor 5 is fixed on the measured component 4 through an adhesive. The signal acquisition and analysis system 7 communicates with the piezoelectric sensor through the preamplifier 6 The sensor 5 is electrically connected; the signal generator 1 can simultaneously output two simple harmonic excitation signals with different frequencies. The signal acquisition and analysis system 7 includes a signal acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com