Sheet metal part vibratory stress relief method and device

A technology of sheet metal parts and vibration aging, which is applied in the manufacturing field of aircraft sheet metal parts, can solve the problems of stress corrosion resistance of sheet metal parts, large deformation of aircraft sheet metal parts, etc., and achieve easy operation, simple structure, and overcome the difficulty of fixing the shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

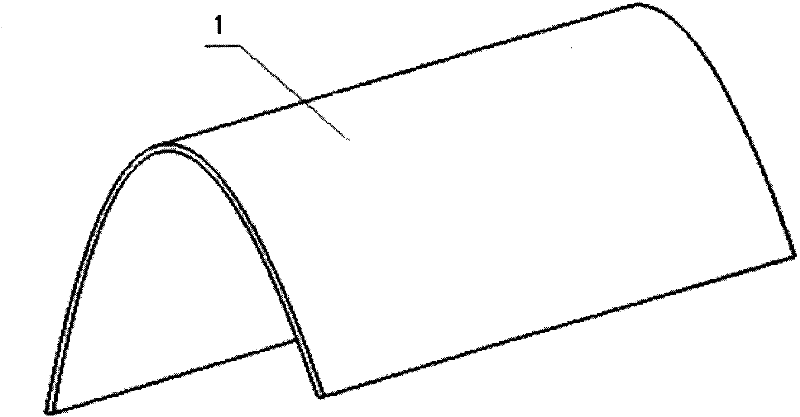

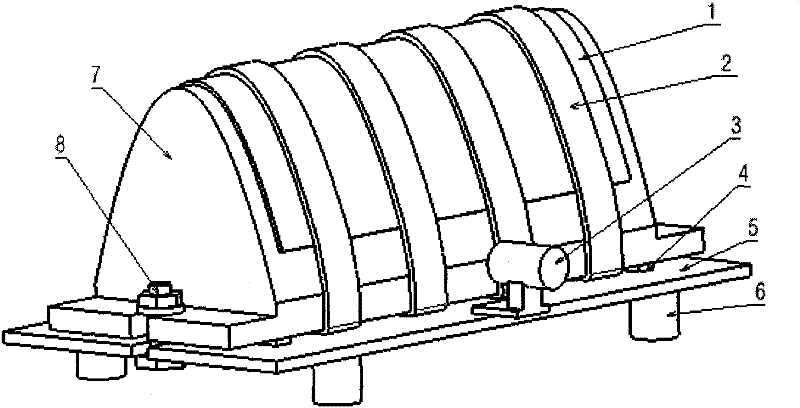

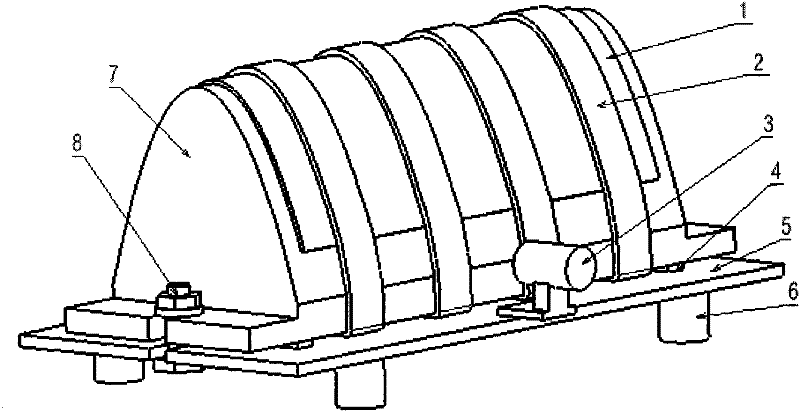

[0015] Referring to the accompanying drawings, the sheet metal part 1 in the embodiment is a processed aircraft front edge skin with a thickness of 1.2mm and a length of 2000mm, made of aluminum alloy 2024, and stretched and formed by a skin stretching machine. In order to eliminate and homogenize the internal stress after processing, the present application proposes a vibration aging method and a vibration aging device. exist figure 2 Among them, the mold tire 7 is used to fix and maintain the shape of the sheet metal part 1, and the shape of the mold tire 7 must match the shape of the sheet metal part 1. The pedestal part of the mold tire 7 in the implementation is a plane, the mold tire 7 is placed on the upper surface of the vibration aging table 5, and the two ends of the mold tire base are fixed with the vibration aging table 5 with the fixture 8. Sheet metal parts 1 are bound on the mold tire 7, between the pedestal of mold tire 7 and the vibratory aging table 5, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com