Method for relieving vibratory stress of loader front frame

A technology of vibration aging and front frame is applied in the field of vibration aging treatment of the front frame of a loader, which can solve problems such as high noise, and achieve the effects of reducing operation time, fewer failures, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

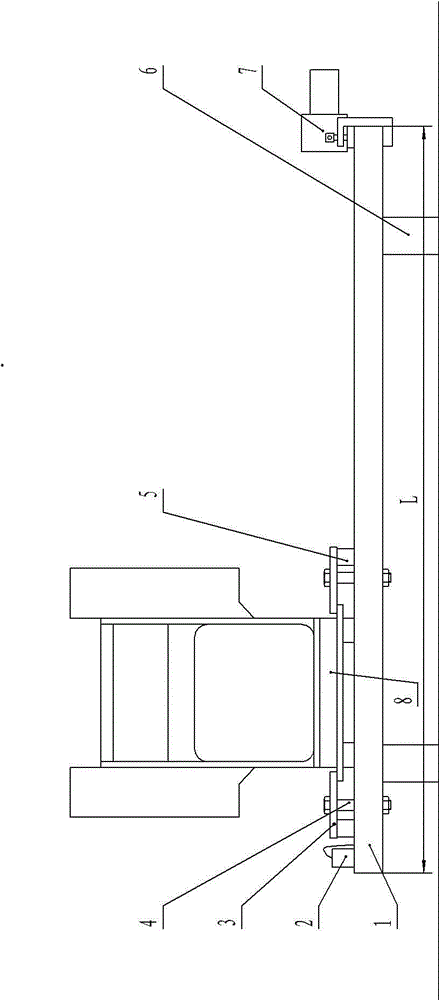

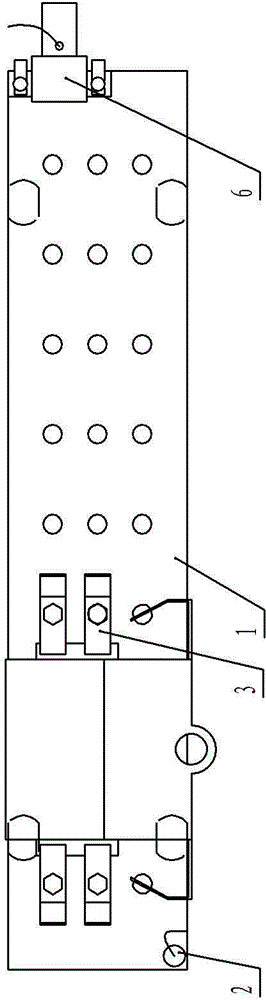

[0019] The front frame of the loader is a box-shaped structural part welded by multiple steel plates, and there are base bosses on both sides of the front frame of the loader; figure 1 and figure 2 The shown loader front frame vibration aging device, this loader front frame vibration aging device includes a vibration exciter 7 and a vibration measuring device 2, there is a platform 1, the length of the platform 1 is 4000 mm, and the width is 800 mm mm, a steel plate with a thickness of 100 mm; there are three rows distributed on the table top of platform 1, and each row has nine uniformly distributed holes with a diameter of 38 mm; each through-hole end at the bottom of the table top of platform 1 is welded with a screw The nut that the hole is communicated with the through hole, the nut of the present embodiment is M36; Four pressing plates 3 and four spacers 5 are placed on the platform 1 table of the present embodiment, and the pressing plates 3 are respectively worn in th...

Embodiment 2

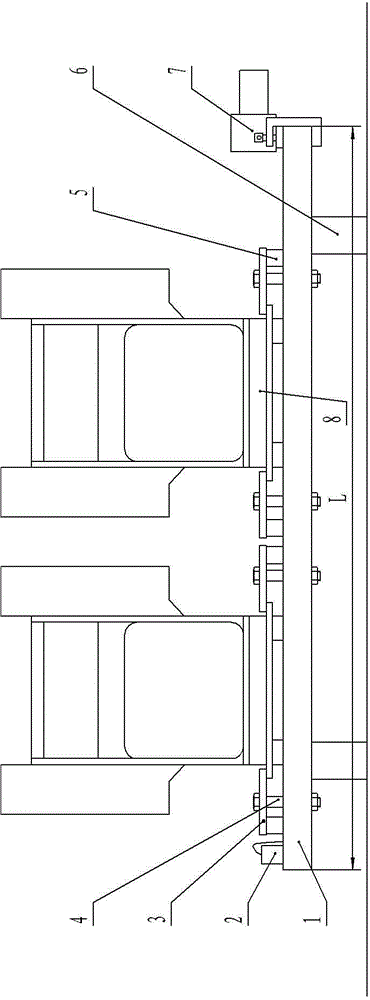

[0023] The front frame of the loader is a box-shaped structural part welded by multiple steel plates, and there are base bosses on both sides of the front frame of the loader; image 3 and Figure 4 The shown loader front frame vibration aging device, this loader front frame vibration aging device includes a vibration exciter 7 and a vibration measuring device 2, there is a platform 1, the length of the platform 1 is 4000 mm, and the width is 800 mm mm, a steel plate with a thickness of 100 mm; there are three rows distributed on the table top of platform 1, and each row has nine uniformly distributed holes with a diameter of 38 mm; each through-hole end at the bottom of the table top of platform 1 is welded with a screw The nut that the hole communicates with the through hole, the nut of the present embodiment is M36; Eight pressing plates 3 and eight pads 5 are placed on the platform 1 table top of the present embodiment, and the pressing plates 3 are respectively worn in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com