Method for controlling fatigue life of stress relief piece through positioning vibratory stress relief

A vibration aging and fatigue life technology, applied in the research on the effect of positioning vibration aging and its process parameters on the fatigue life of aging parts, and in the field of positioning vibration aging controlling the fatigue life of aging parts. Avoid blindness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

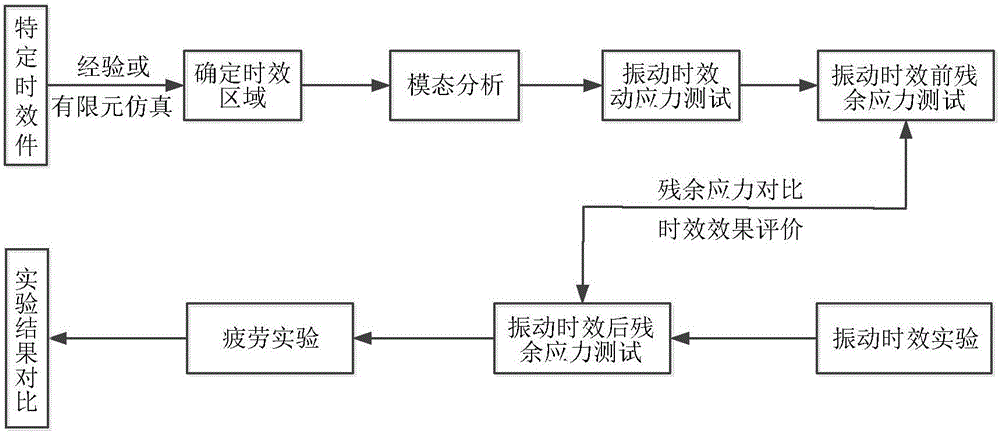

[0031] See figure 1 , a method for positioning vibration aging control fatigue life of aging parts described in the present invention, the specific steps of the method are as follows:

[0032] Step 1: According to the material and structural form of the aging parts, and according to the residual stress test experience in the production practice process and combined with the finite element numerical simulation, analyze the distribution law of the residual stress of the aging parts, and determine the area where the aging parts need to be aged;

[0033] Step 2: Carry out modal analysis on the aging parts, optimize the mode shape, and make the aging area of the aging parts consistent with the fatigue area;

[0034] Step 3: Determine the installation form and excitation frequency of the aging parts according to the mode shape selected in Step 2;

[0035] Step 4: Stick the strain gauge on the aging area of the aging piece. According to step 3, install the aging piece on the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com