Frequency self-adaptive oscillation time-effect method and device

A technology of frequency self-adaptation and vibration aging, which is applied in the field of vibration aging, can solve problems that affect the working state and service life of the motor, reduce the aging efficiency of the workpiece, and the workpiece cannot reach resonance, so as to track the change of resonance frequency in time and improve the vibration aging effect, the effect of avoiding early damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A frequency self-adaptive vibration aging method of the present invention searches for the precise natural frequency of the workpiece 1 (thick aluminum plate) through a given initial frequency, and then implements frequency self-adaptation according to the principle that the acceleration value is the largest at the natural frequency with the acceleration as the feedback amount Get used to tracking.

[0022] Describe in detail below in conjunction with accompanying drawing:

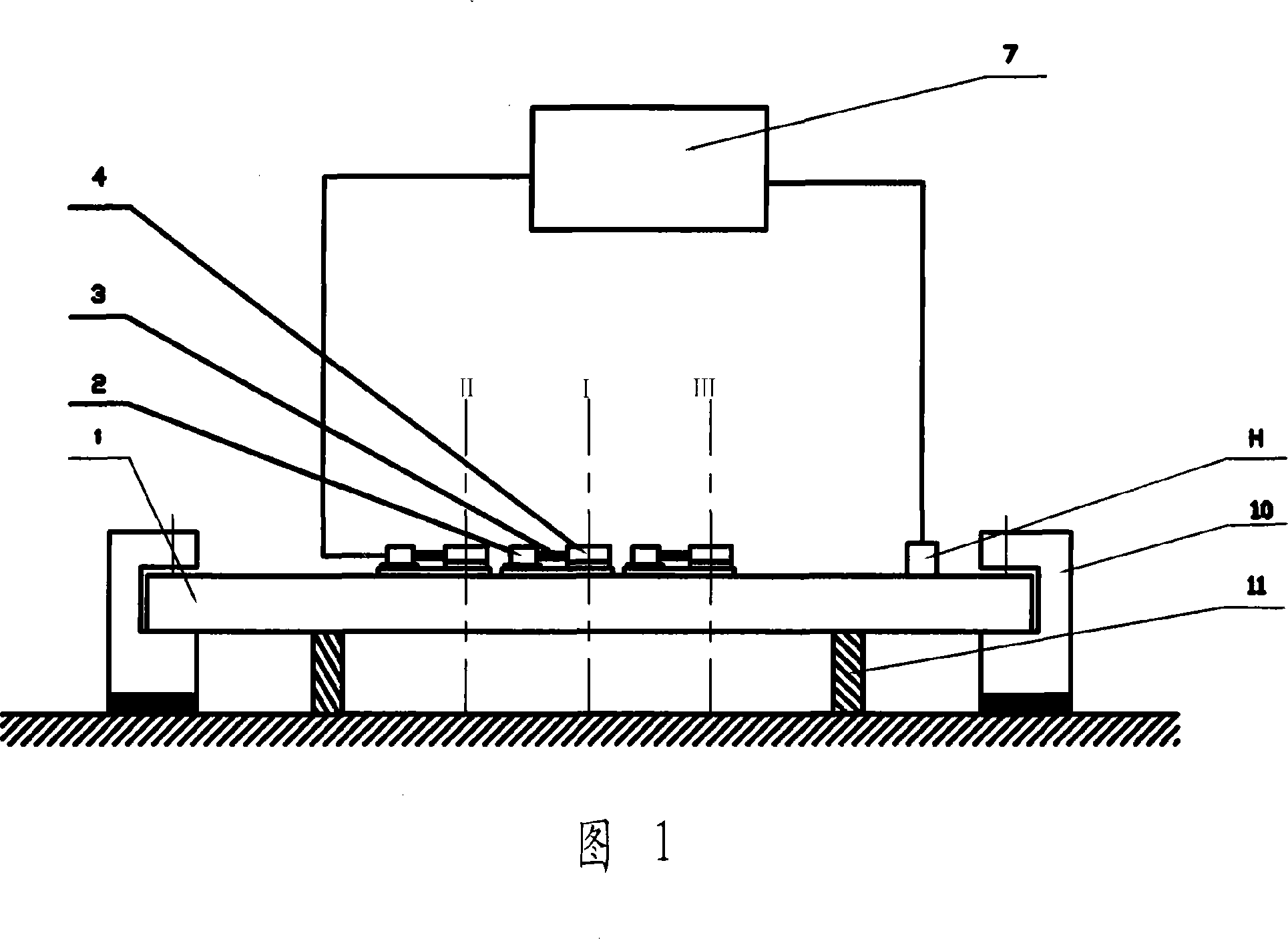

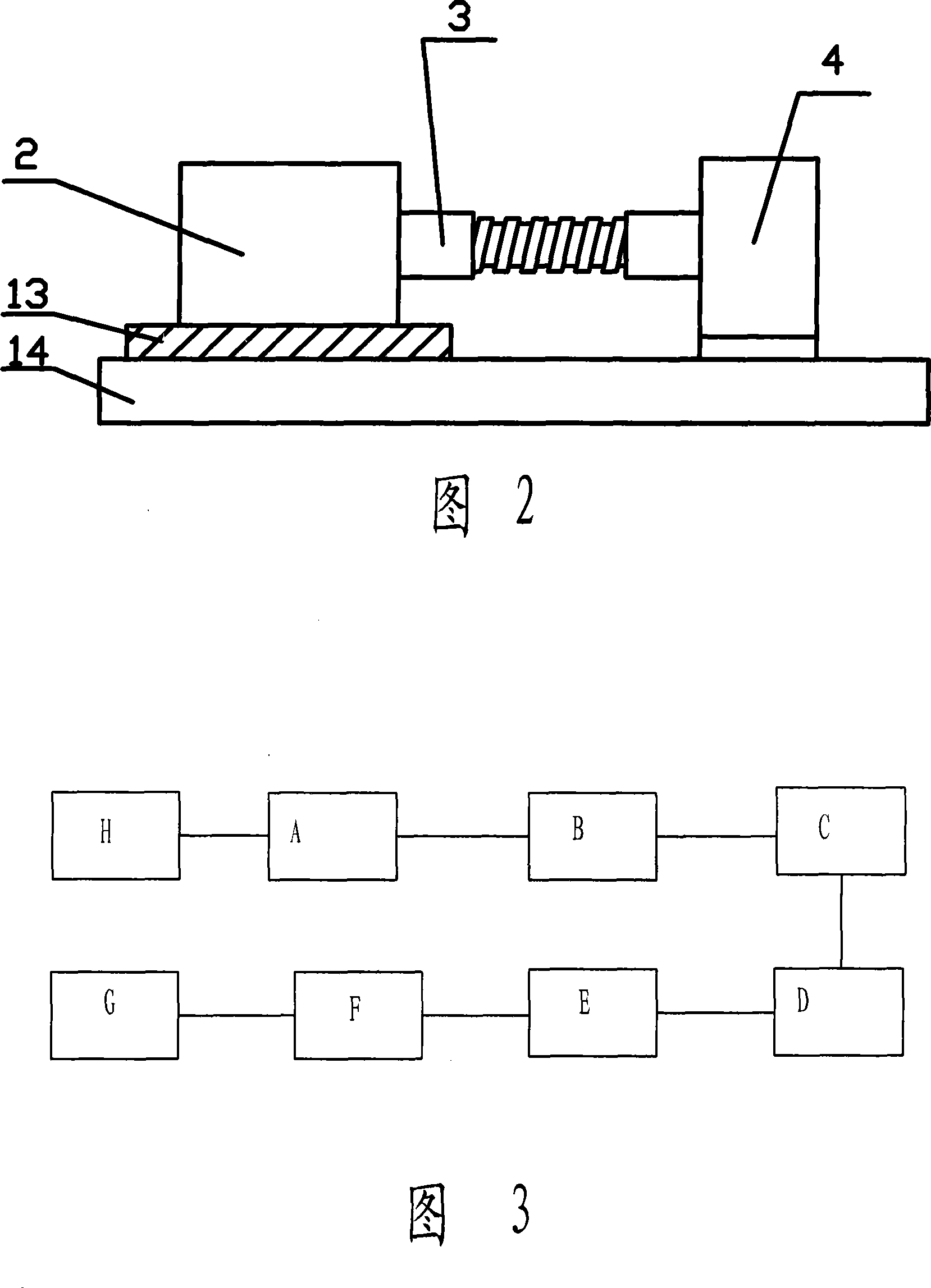

[0023] Referring to accompanying drawings 1, 2, and 3, the workpiece 1 is supported on the foundation by an elastic support 11. In order to make the dynamic stress on the workpiece 1 more uniform, mass blocks 10 are placed at both ends of the workpiece 1, and the masses 10 are padded There are elastic pieces. The bottom of the vibration box 4 is rigidly connected to the workpiece 1 through the machine base 14, and one end is connected to the motor 2 through the flexible shaft 3. The bottom of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com