Flexural coupling resonance type vibratory stress relief device and implementation method thereof

A technology of coupling resonance and vibration aging, which is applied in the field of mechanical processing, can solve problems such as inability to handle, achieve a wide range of applications, and eliminate the effect of workpiece residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

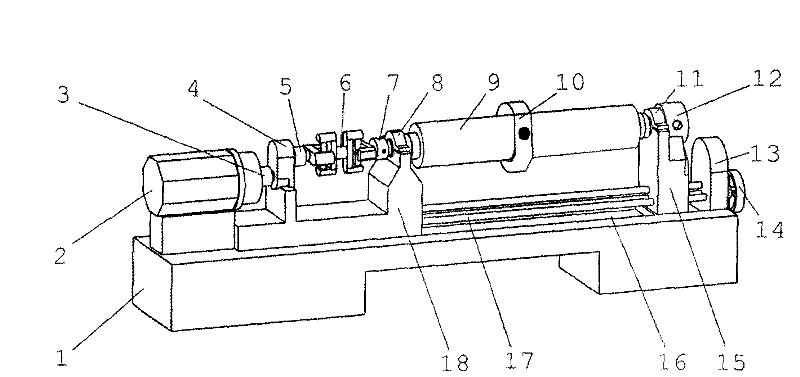

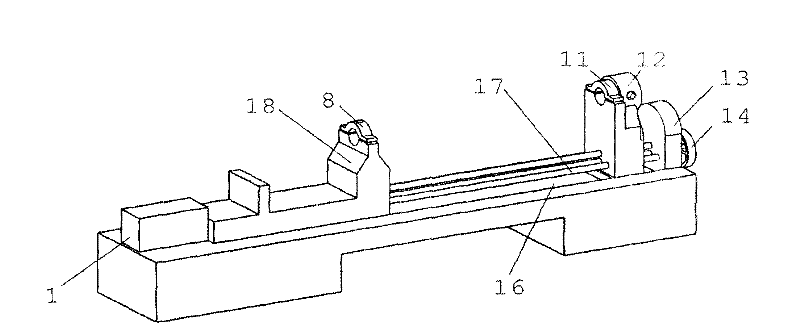

[0025] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

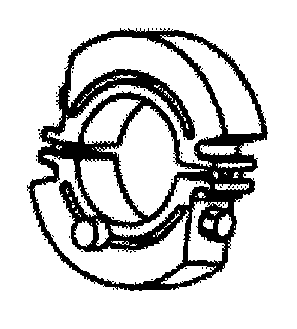

[0026] The bending-torsion coupling resonance vibration aging device of the present invention includes a workbench, an adjustable-speed main transmission system, an eccentric mass 10 and a torque increasing device 12 .

[0027] control figure 1 and figure 2 , The workbench is made up of machine base 1, fixed support platform 18, sliding table 15, leading screw 17, machine base baffle plate 13 and sliding table adjusting disc 14. Fixed support table 18 is fixed on the machine base 1, and fixed support sliding bearing 8 is installed on the fixed support table 18, is used for supporting workpiece 9, and sliding table 15 is arranged on the sliding guide rail 16, and sliding table supporting bearing 11 is arranged on it, and wire One end of the bar 17 is connected with the fixed support platform 18, and the other end passes through the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com