Cylindrical cam excitation driven bending-torsional coupling resonance type residual stress relieving device

A technology of cylindrical cam and coupling resonance, which is applied in the direction of improving process efficiency, etc., to achieve the effects of strong flexibility, large adaptability and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

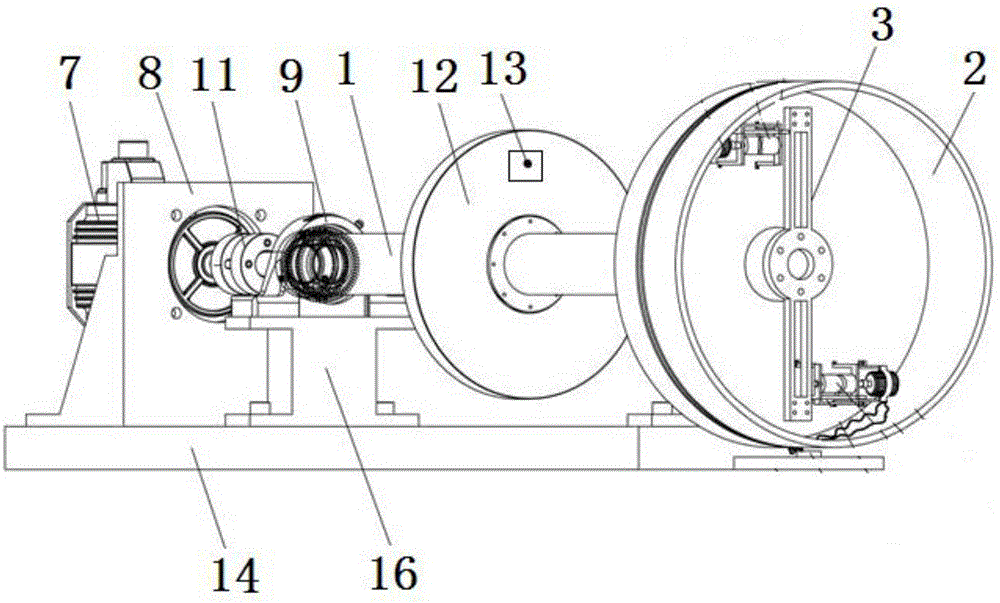

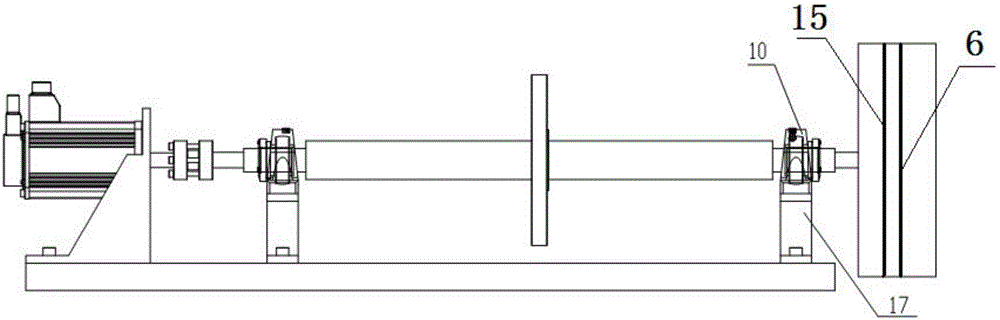

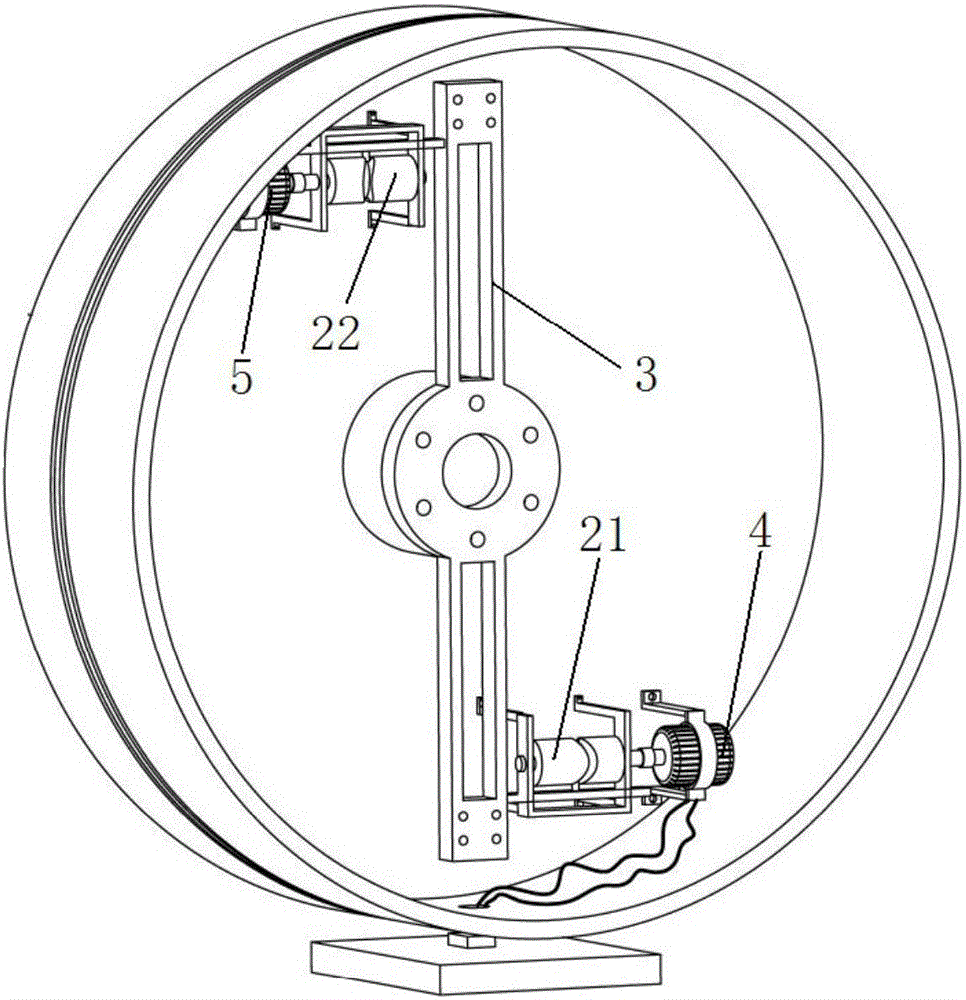

[0028] Bending-torsion coupling resonance residual stress relief device induced by cylindrical cam excitation, including rotating shaft 1, first bearing 9, second bearing 10, first bearing seat 16, second bearing seat 17, motor 7, coupling 11, chassis 14. Disc 12, eccentric mass 13 and torsional vibration exciter, said torsional vibration exciter includes excitation frame 2, excitation force arm 3, positive electrode ring 6, negative electrode ring 15, first cylindrical cam excitation device, the second cylindrical cam actuator, positive brush 19, negative brush and brush base 20; the first cylindrical cam actuator includes the first grooved cylindrical cam 21, the first actuating motor 4, the first actuating lever 22 and the first actuating slider 23, the second cylindrical cam actuator includes a second grooved cylindrical cam 22, a second actuating motor 5, a second actuating rod and a second actuating slider;

[0029] The rotating shaft 1 is installed on the chassis 14 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com