Vibration aging correction method for deformation of cylindrical parts and anti-deformation restraint fixture

A vibration aging and anti-deformation technology, applied in the field of parts deformation correction, can solve problems such as part deformation and internal stress cannot be eliminated, and achieve the effect of eliminating internal stress, improving processing efficiency and processing success rate, and saving materials and processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

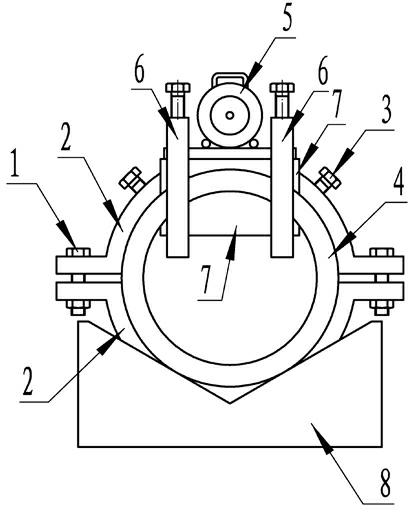

[0032] A method for correcting the deformation of a cylindrical part by vibration aging according to the present invention, the cylindrical part is installed so that the natural frequency or resonance frequency of the cylindrical part is within the working range of the exciter of the vibration aging equipment, and the deformed part is fixed with a clamp Anti-deformation constraints are performed on the deformed part of the part, and then vibration aging treatment is performed on the cylindrical part.

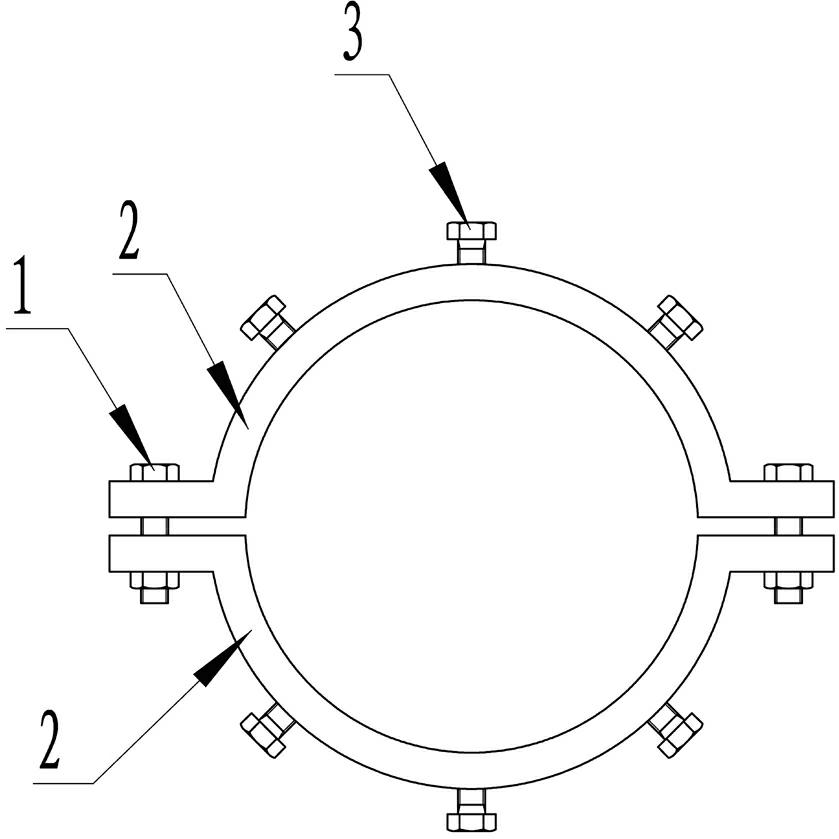

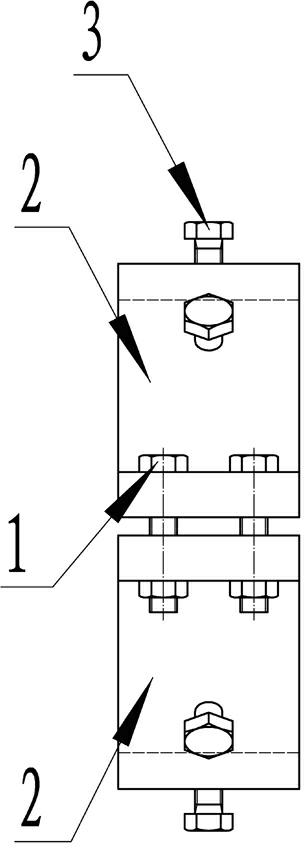

[0033] Anti-deformation restraint fixtures (such as figure 1 , 2 As shown), it includes two semi-circular hoop-shaped anti-deformation restraint clamp bodies 2 fastened by anti-deformation restraint clamp bolts 1, and anti-deformation adjustment screws 3 are provided on the arc surface of the semi-circular hoop. When in use, first surround two semicircular hoops on the outer circle of the cylindrical part 4, and connect and clamp the two parts of the anti-deformation restrainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com