Vibratory stress relief device for autoclave body

A vibrating aging and autoclave technology, applied in the field of mechanical processing equipment manufacturing, can solve the problems of high aging cost, large investment in aging equipment, and difficult thermal aging at the equipment installation site, so as to reduce the thermal aging cost, eliminate welding residual stress, The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

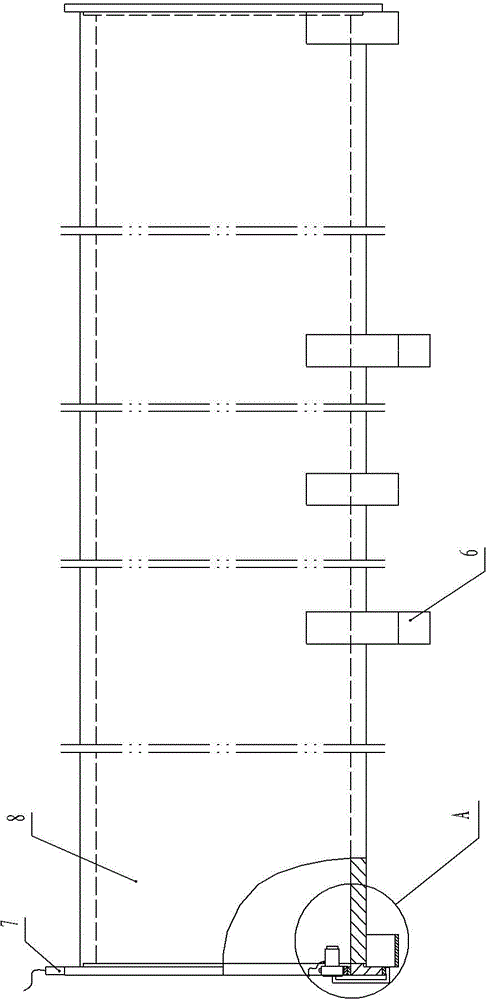

[0017] like figure 1 The kettle body 8 shown is composed of a cylinder body and a toothed circular flange welded at both ends of the cylinder body, and a plurality of supports are welded on the lower part of the cylinder body; the kettle body 8 in this embodiment has a diameter of 2000 mm, a length of 30938 mm, and a weight of 28 tons, a support is welded every 3500 mm in the lower part of the cylinder.

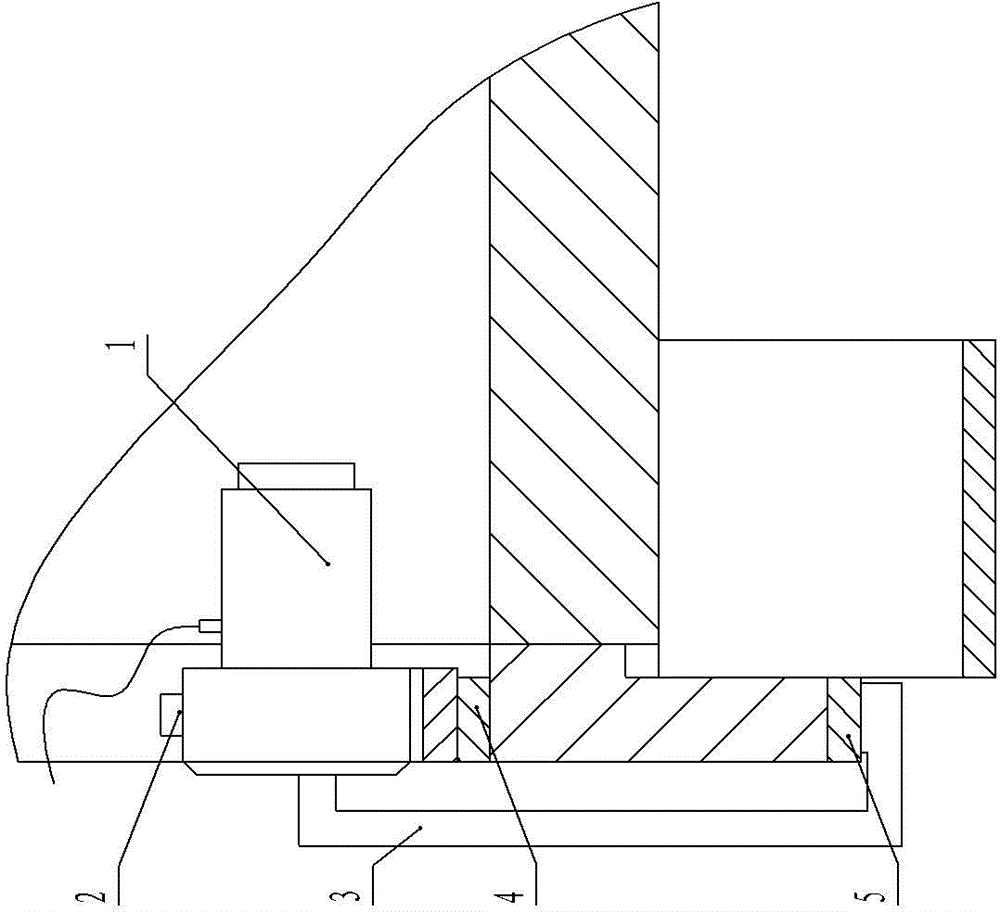

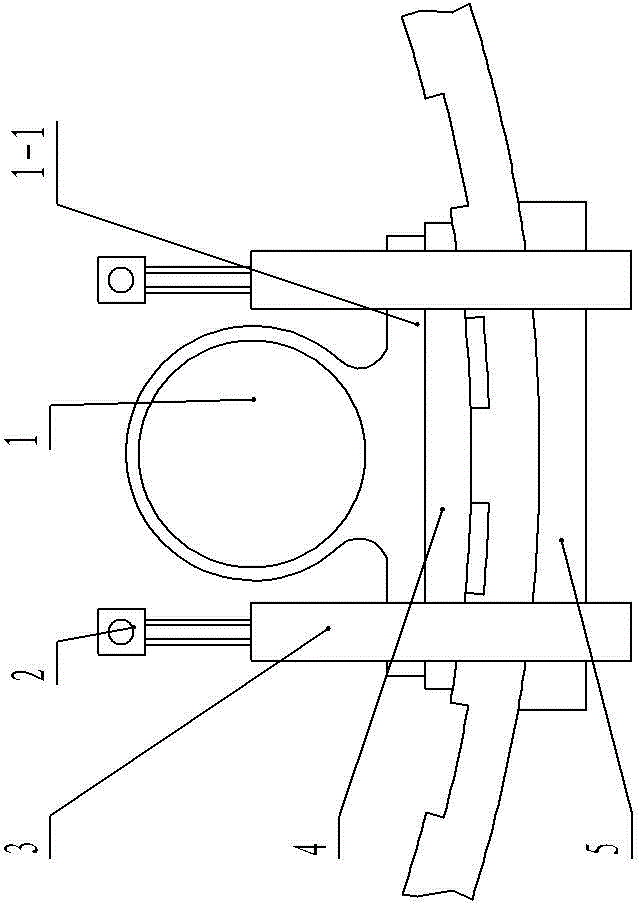

[0018] like figure 2 , image 3 and Figure 4 The shown autoclave body vibration aging device, this autoclave body vibration aging device includes an exciter 1, the lower end of the exciter 1 has two ear plates 1-1 protruding sideways, The two lugs 1-1 of the device 1 are provided with arcuate pliers 3, and the upper end of the pliers 3 is threaded with a screw 2; An upper backing plate 4 and a lower backing plate 5 are provided, the bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com