Method for preventing drill column from generating torsional resonance and flexible torque shock absorber

A shock absorber and flexible technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problem that torque vibration cannot be weakened or eliminated, so as to improve drilling speed and well quality, reduce drilling cost and improve work stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

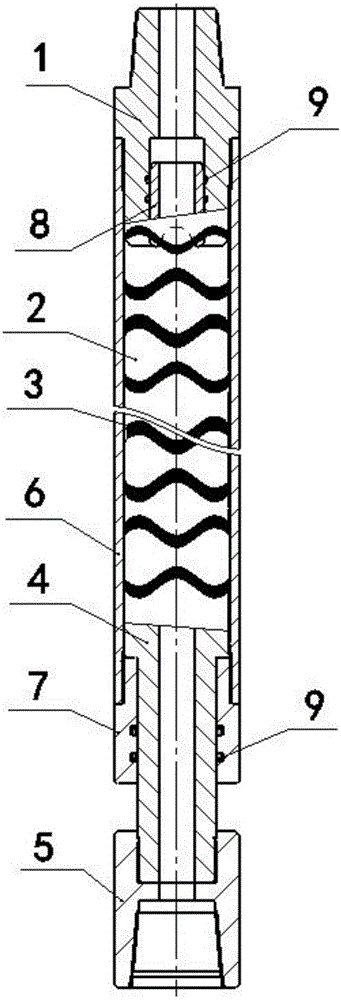

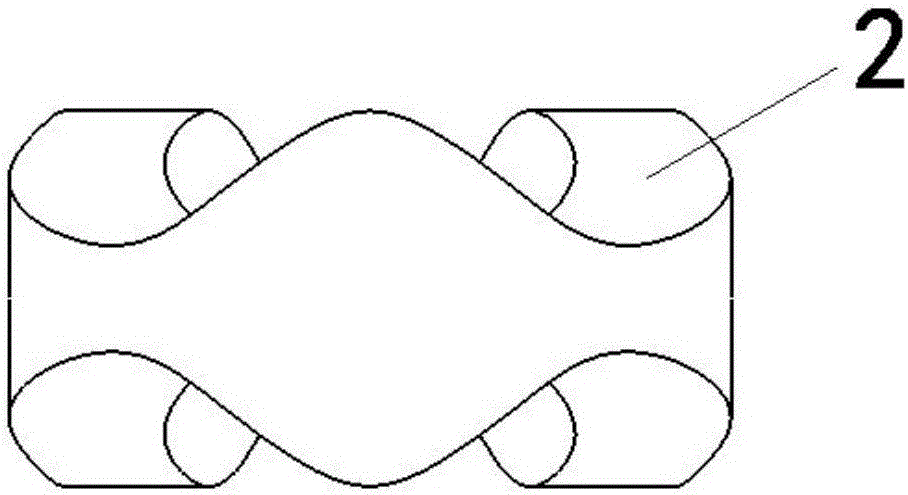

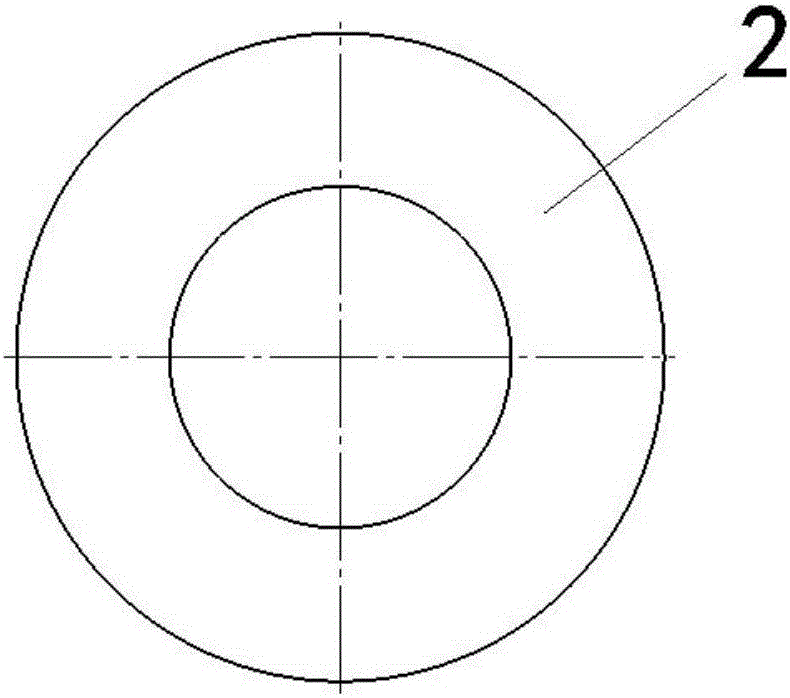

[0022] Embodiment of the present invention: the structural representation of flexible torque shock absorber is as figure 1 As shown, it includes a cylinder body 6 and an upper drive joint 1 fixedly connected to both ends of the cylinder body 6 and a sealed outer cylinder 7. A lower drive shaft 4 that can slide up and down is arranged in the sealed outer cylinder 7, and the lower end of the lower drive shaft 4 is fixed. The lower joint 5 is connected, and eight flexible torque transmission short joints 2 are arranged between the upper drive joint 1 and the lower drive shaft 4 in the cylinder 6, see Figure 2-5 , there are sinusoidal meshing teeth on both ends of each flexible torque transmission sub-joint 2, adjacent flexible torque transmission su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com