A bidirectional longitudinal-torsional compound vibration device

A technology of compound vibration and longitudinal torsion, which is applied in the direction of fluid using vibration, can solve the problems of poor interchangeability and inability to realize rapid tool change, etc., and achieve the effect of simple vibration form, simple power supply form and good interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

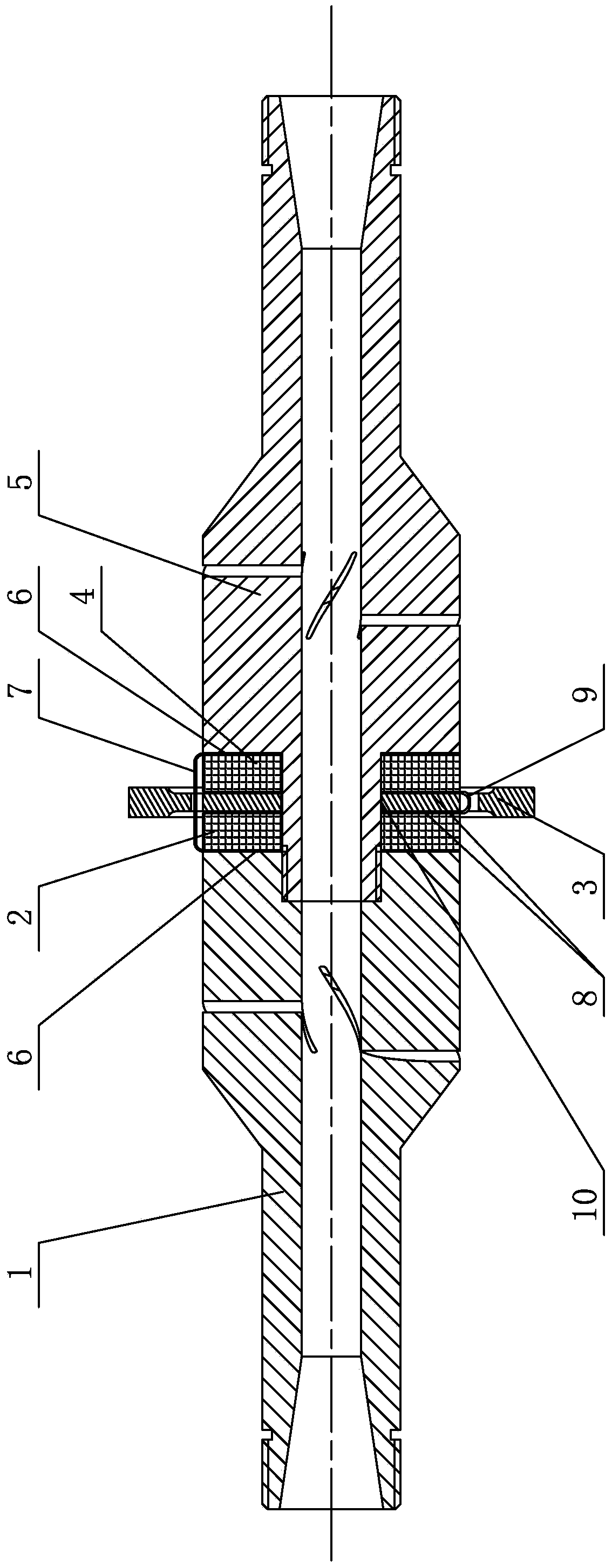

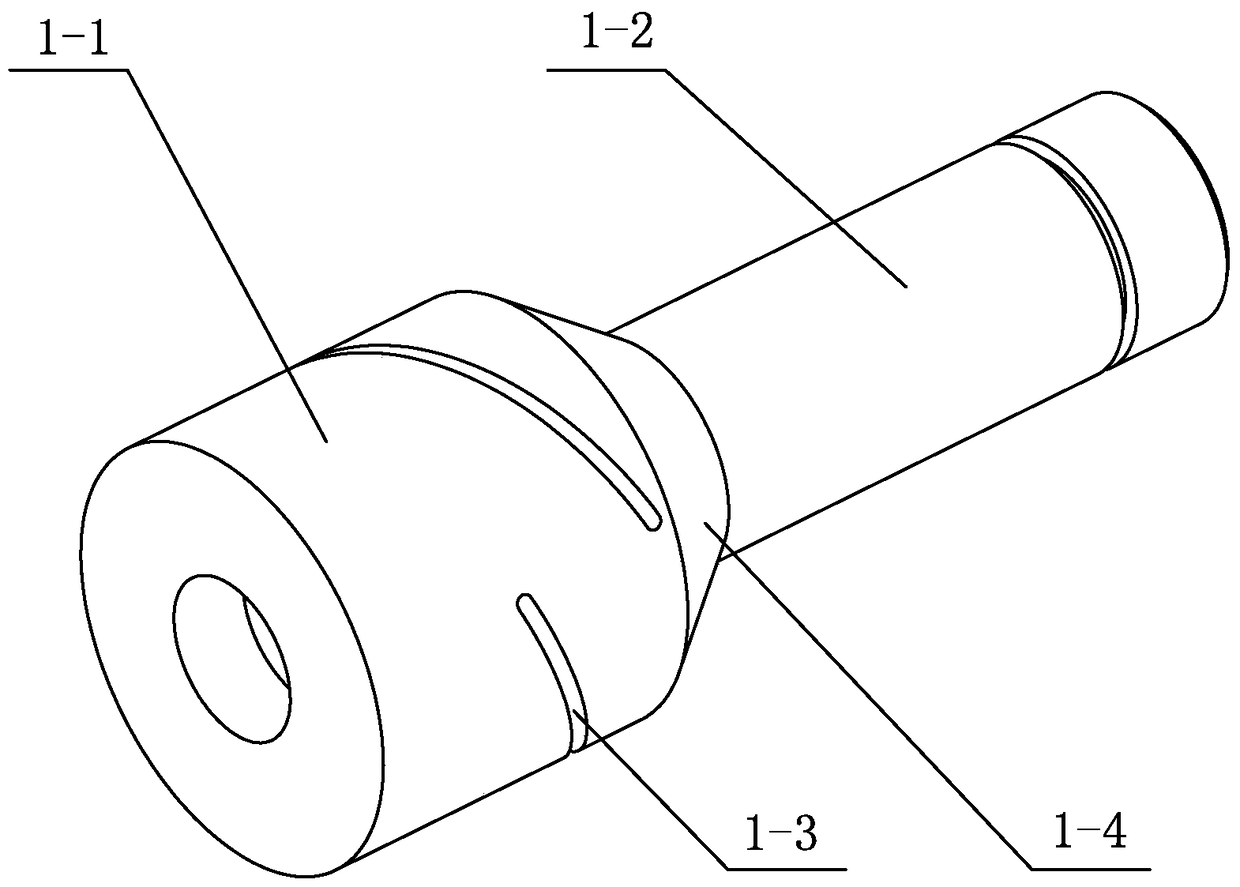

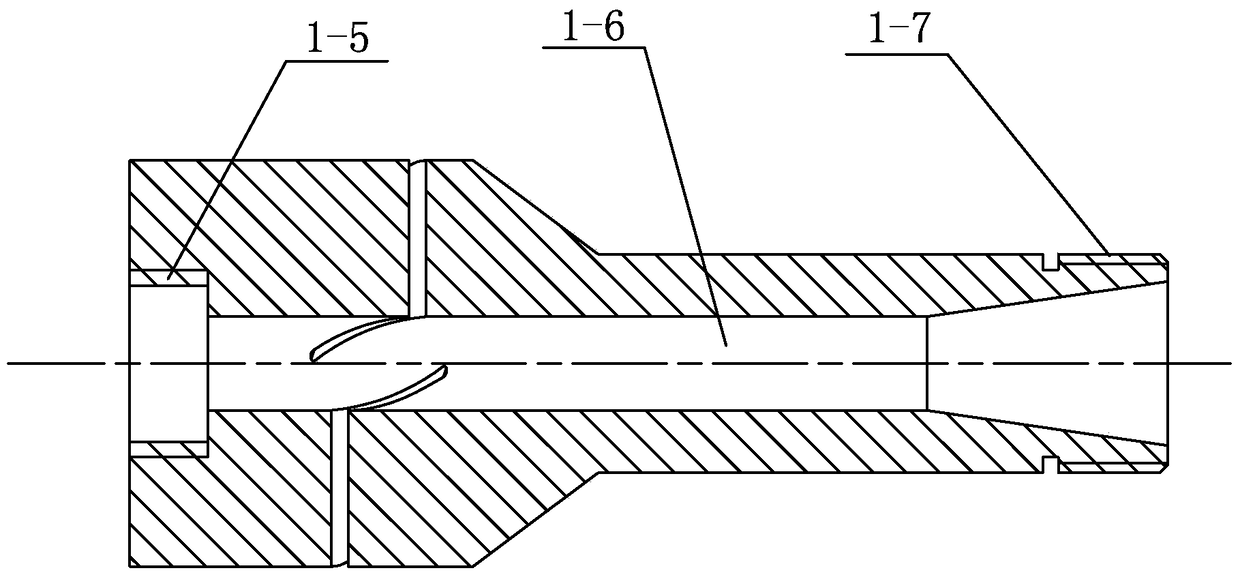

[0016] Specific implementation mode one: combine figure 1 This embodiment is described. A bidirectional longitudinal-torsional compound vibration device described in this embodiment includes a front cover 1, a first annular piezoelectric ceramic 2, a mounting plate 3, a second annular piezoelectric ceramic 4, a rear cover 5, a first electrical One end of the front cover 1 and one end of the back cover 5 are plugged in, and the connection between the front cover 1 and the back cover 5 is sequentially fitted with a first ring-shaped pressure ring from one end of the front cover 1 to one end of the back cover 5. The electric ceramic 2 , the mounting plate 3 , and the second annular piezoelectric ceramic 4 , the first electrode end and the second electrode end are arranged symmetrically at the joint between the front cover 1 and the rear cover 5 . The front cover 1 and the rear cover 5 are fastened with epoxy glue, and the first annular piezoelectric ceramic 2 and the second annul...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 Describe this embodiment, the first electrode end of a kind of two-way vertical torsional compound vibration device described in this embodiment includes two first electrodes 6 and a first electrode connection copper sheet 7, the end surface of one end of the front cover 1 is connected with the first ring A first electrode 6 is arranged between the piezoelectric ceramics 2, and a first electrode 6 is arranged between the end face of one end of the back cover 5 and the second annular piezoelectric ceramic 4, and the two first electrodes 6 are connected to copper via the first electrodes. Slice 7 is connected. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the second electrode end of a bidirectional longitudinal-torsional compound vibration device described in this embodiment includes two second electrodes 8 and a second electrode connection copper sheet 9, the first annular piezoelectric ceramic 2 and the mounting plate A second electrode 8 is provided between 3, a second electrode 8 is provided between the second annular piezoelectric ceramic 4 and the mounting board 3, and the two second electrodes 8 are connected through a second electrode connection copper sheet 9.

[0021] The first electrode connection copper sheet 7 and the second electrode connection copper sheet 9 respectively connect all positive electrodes and all negative electrodes of the piezoelectric ceramics together, and the negative electrodes are connected to the front cover 1 and the rear cover 2 and grounded. Other components and connections are the same as those ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com