Low cost and high efficient soundproof material and manufacturing method thereof

A technology of sound insulation material and production method, which is applied in the direction of instruments and sound-emitting devices, can solve the problems of endangering human health, producing toxic gas, and the effect of high-efficiency sound insulation materials is not obvious, so as to improve the heat resistance and aging resistance, the effect The effect of good, good isolating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

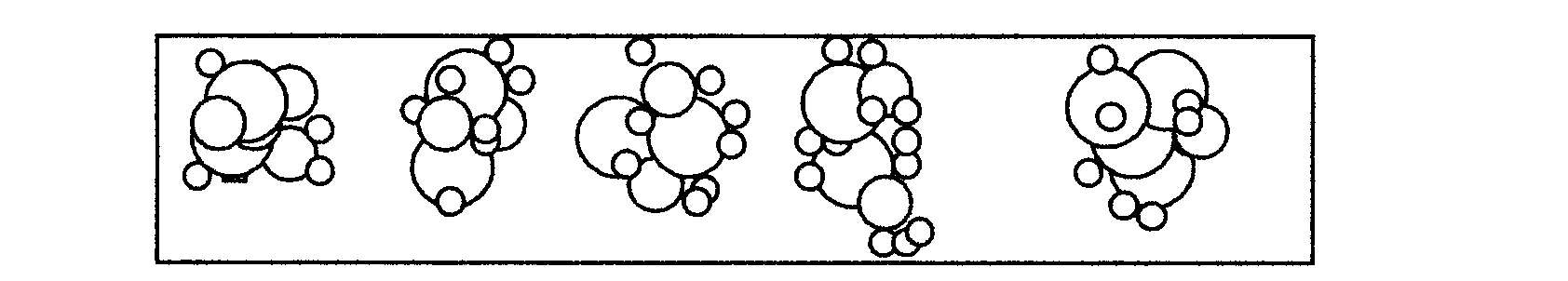

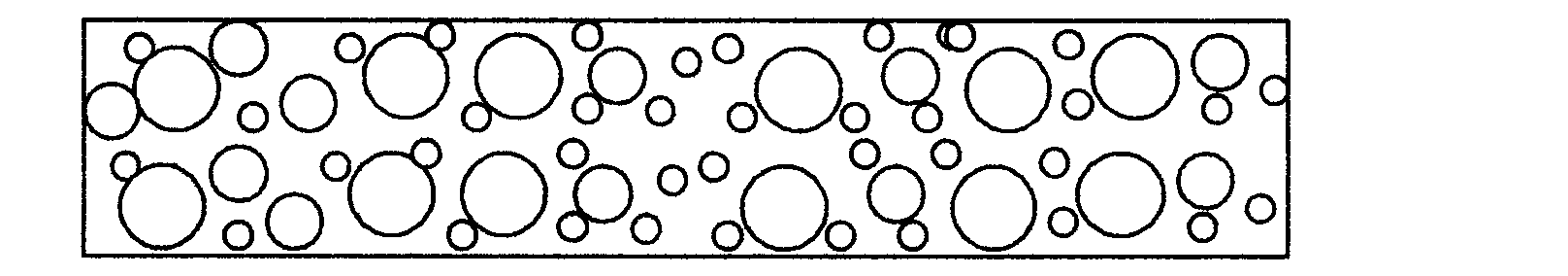

[0045] correspond figure 1 / sound insulation material shown in Table 1

[0046] raw material

[0047] Vinyl chloride-vinyl acetate copolymer 6.0kg

[0048] Ethylene-vinyl acetate copolymer (EVA) 13.0kg

[0049] Polypropylene (PP) 18.0kg

[0050] Isopropyl tri(dioctyl pyrophosphate) titanate 1.0kg

[0051] Liquid paraffin oil 1000ml

[0052] Light calcium carbonate 53.2kg

[0053] Petroleum resin C9 3.0kg

[0054] 2,6-di-tert-butyl-p-cresol 2.0kg

[0055] Triphenyl phosphate 1.0kg

[0057] Preparation and pretreatment of nano-submillimeter inorganic fine powder

[0058] We choose the XMQ-350×160 ball mill, with the same parameter configuration, such as at a constant speed of 280rpm, the same sample processing capacity (2kg), ball mill parameters (amount of 3kg, diameter 1cm), and grind for 10 days respectively to obtain spherical samples 1; 1.5 days, get spheroid 2; 5 hours, get spheroid 3. Then, the materials that have been ground for ...

Embodiment 2

[0069] correspond figure 2 / sound insulation material shown in Table 2

[0070] raw material:

[0071] Vinyl chloride-vinyl acetate copolymer 6.0kg

[0072] Ethylene-vinyl acetate copolymer (EVA) 13.0kg

[0073] Polypropylene (PP) 18.0kg

[0074] Isopropyl tri(dioctyl pyrophosphate) titanate 1.0kg

[0075] Liquid paraffin oil 500ml

[0076] Cyclohexane 300ml

[0078] Light calcium carbonate 53.2kg

[0079] Petroleum resin C9 3.0kg

[0080] 2,6-di-tert-butyl-p-cresol 2.0kg

[0081] Triphenyl phosphate 1.0kg

[0083] Preparation and pretreatment of nano-submillimeter inorganic fine powder

[0084] With embodiment 1.

[0085] Calcium Carbonate Surface Treatment

[0086] Mix paraffin oil, cyclohexane and petroleum ether evenly to prepare a diluent mixture. Stir the mixture of isopropyl tris(dioctyl pyrophosphate) titanate and diluent evenly to prepare isopropyl tris(dioctyl pyrophosphate) titanate dispers...

Embodiment 3

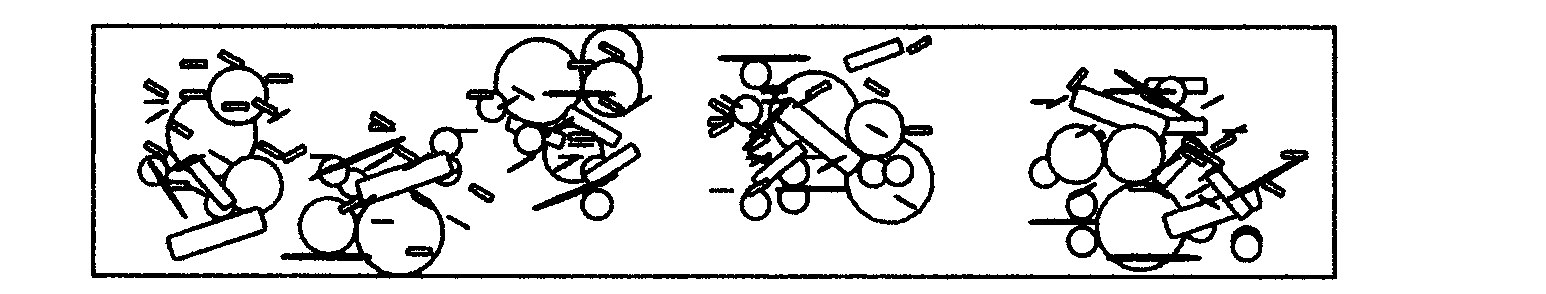

[0096] correspond image 3 / sound insulation material shown in table 3

[0097] raw material

[0098] Vinyl chloride-vinyl acetate copolymer 6.0kg

[0099] Ethylene-vinyl acetate copolymer (EVA) 13.0kg

[0100] Polypropylene (PP) 18.0kg

[0101] Isopropyl tri(dioctyl pyrophosphate) titanate 1.0kg

[0102] Liquid paraffin oil 1000ml

[0103] Millimeter grade light calcium carbonate 22.2kg

[0104] Millimeter mica 18.5kg

[0105] Millimeter wollastonite 12.5

[0106] Petroleum resin C9 3.0kg

[0107] 2,6-di-tert-butyl-p-cresol 2.0kg

[0108] Triphenyl phosphate 1.0kg

[0110] Preparation and pretreatment of nano-submillimeter inorganic fine powder

[0111] Millimeter grade light calcium carbonate, mica sheet and wollastonite are ground into multimode fine powder with the same method of embodiment 1.

[0112] Calcium Carbonate Surface Treatment

[0113] The mica flakes and wollastonite were processed in the same manner as in Example 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com