Fast test method of shearing resistance of bituminous mixture

A technology of asphalt mixture and test method, which is applied in the direction of applying stable shear force to test the strength of materials, can solve the problems of complex test steps, neglect, and high requirements for users, and achieve the effect of convenient test process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

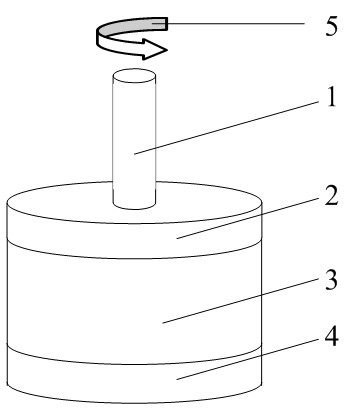

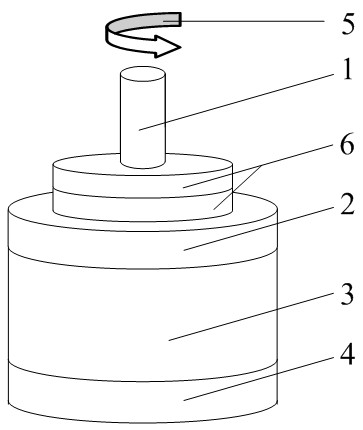

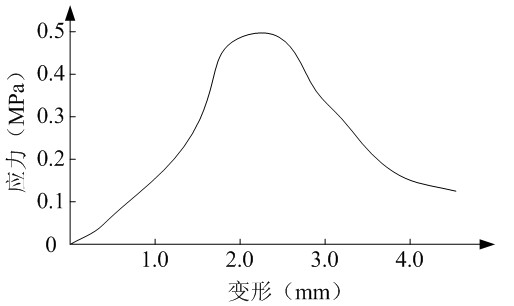

[0047] Example: A kind of rapid testing method of asphalt mixture anti-shear performance, comprises the steps:

[0048] (1) Preparation of asphalt mixture specimens

[0049] According to the gradation and asphalt-stone ratio of the asphalt mixture to be evaluated, three groups of 12 Marshall specimens were formed in the laboratory, and the porosity of the specimens was controlled according to the design porosity. Cut and smooth the formed Marshall test piece, specifically: for asphalt mixture with a nominal maximum diameter of not less than 19mm, saw the prepared Marshall test piece into a test piece with a thickness of about 50mm; for the nominal maximum diameter For the asphalt mixture not less than 12.5mm, saw the prepared Marshall specimens into specimens with a thickness of about 40mm. Place the cylindrical specimen obtained after cutting in air at room temperature until the surface of the specimen is dry.

[0050] (2) Preparation before shear test

[0051] Apply hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com