Speed limiter of elevator

A technology of elevator speed limiter and overrunning clutch, which is applied to clutches, one-way clutches, elevators, etc., can solve the problems of discontinuous speed capture of speed limiter action, discontinuous action, influence of speed limiter, etc., so as to achieve safe elevator operation. Reliable, solve discontinuity, stable effect of pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

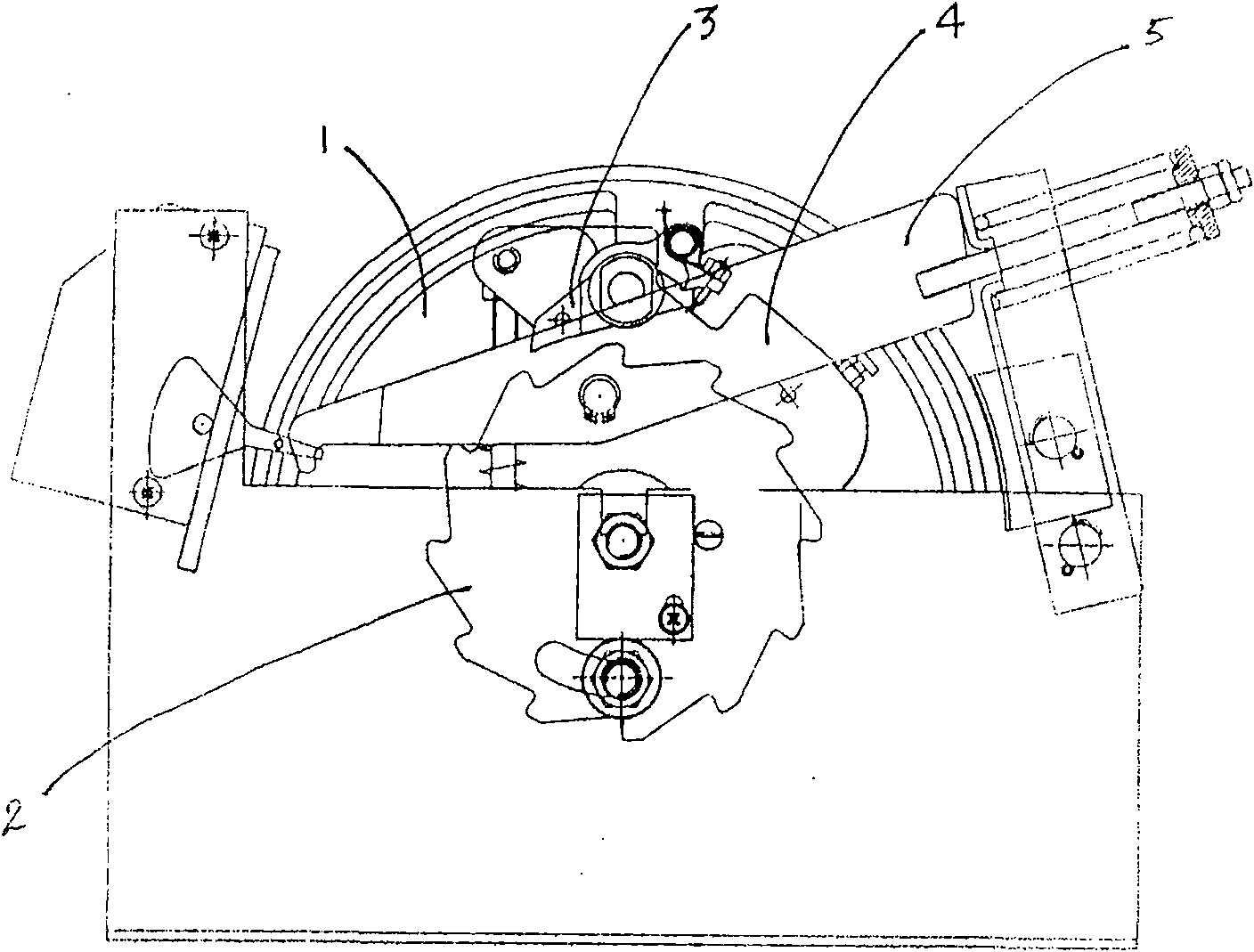

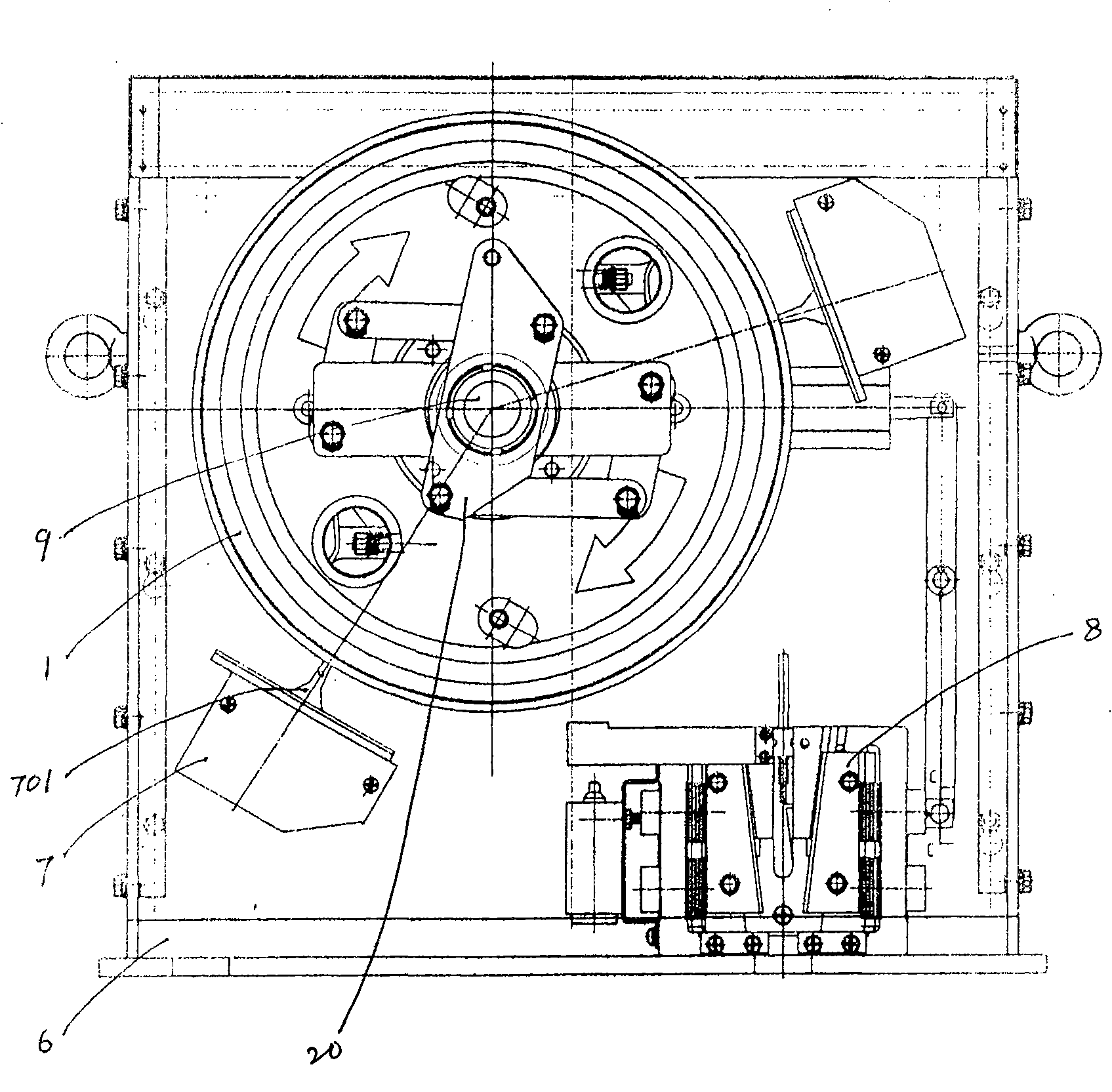

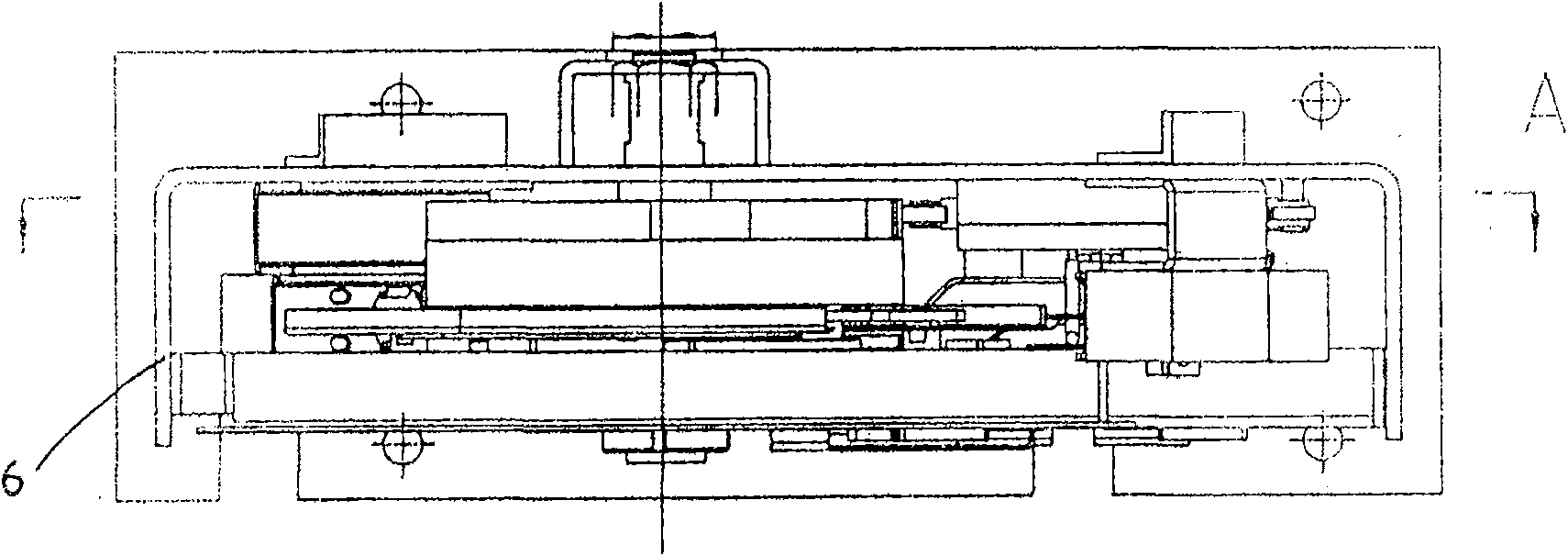

[0019] Depend on Figure 2-Figure 5 As shown, a kind of elevator overspeed governor of the present invention comprises frame 6, sheave 1, sheave shaft 9, overspeed switch 7, roller type overrunning clutch; Said sheave 1 is installed on frame by sheave shaft 9 6, the sheave 1 is equipped with a steel wire rope; said overspeed switch 7 is installed on the frame 6, and the overspeed switch 7 has a plate 701 that can contact with the roller type overrunning clutch. When the elevator overspeeds, the roller type overruns The clutch hits the beating plate of the overspeed switch under the action of centrifugal force to trigger the electrical switch action; the roller type overrunning clutch is composed of a group of inner and outer friction wheels 11, 10 and inner and outer friction wheels coaxially installed with the sheave. The friction pair composed of the friction roller 15 between the friction wheels and the centrifugal quadrilateral component group are composed; the said inner ...

Embodiment 2

[0022] In Embodiment 1, the outer friction wheel 10 and the frame 6 are fixed so that the outer friction wheel 10 is tightly fitted with the sheave shaft, and the rest of the embodiment 1 is repeated.

Embodiment 3

[0024] In embodiment 1, change the fixation of inner friction wheel 11 and sheave 1 to be that outer friction wheel 10 is fixed with sheave 1, and outer friction wheel is not fixed with frame 6; Fixed, all the other repeat embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com