Reinforced earth retaining wall model test apparatus and method

A model test device and retaining wall technology, applied in the field of road engineering and geotechnical engineering, can solve the problem that the internal stress, strain, limit layout of the model cannot be accurately and comprehensively obtained, and the equipment for centrifugal model test is expensive to manufacture, maintain and use. and other problems, to achieve the effect of small lateral deformation, large lateral stiffness, and good plane strain state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0041] Refer to attached Figure 4-Figure 5 As shown, a reinforced soil retaining wall model test device includes a model box 1, a retaining wall panel 5, a filler 7, a vertical load loading system 10 and a testing system.

[0042] The filler 7 is filled in the model box 1, and the retaining wall panel 5 is arranged in front of the model box 1; the vertical load loading system 10 is arranged above the model box 1 to apply vertical pressure to the model. The test system includes a stress test device, a displacement test device and a deformation test device inside the retaining wall.

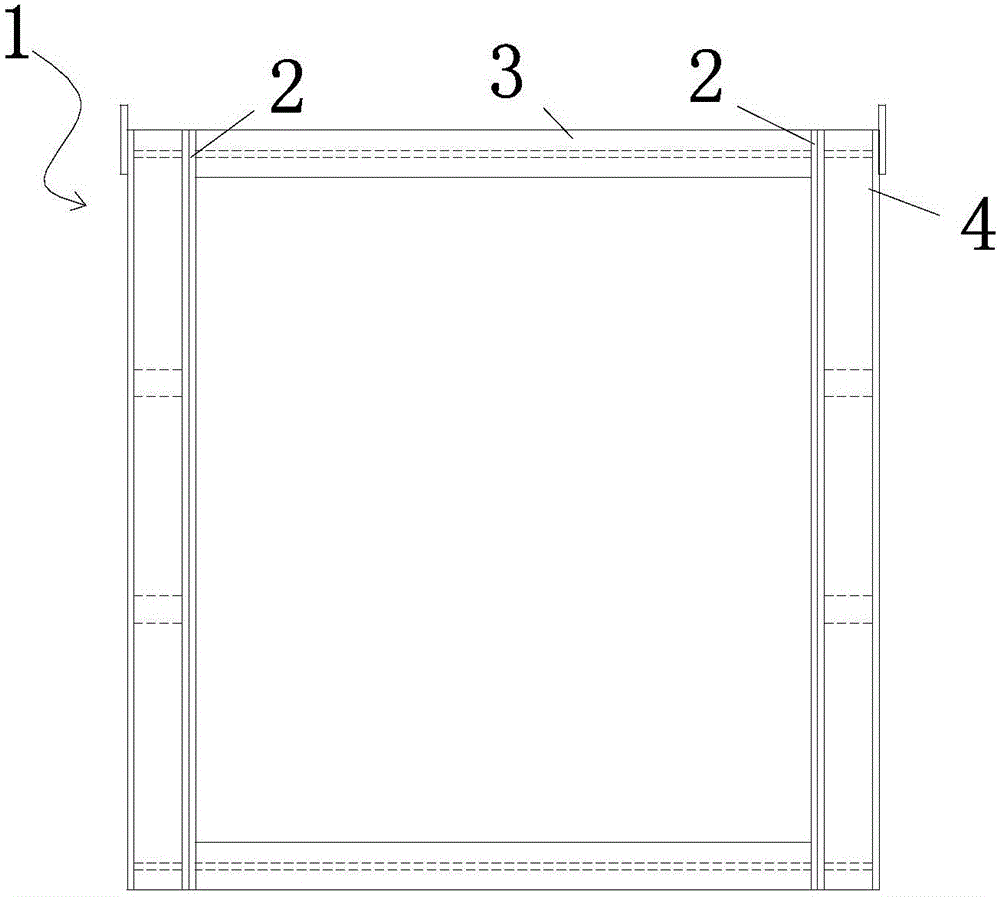

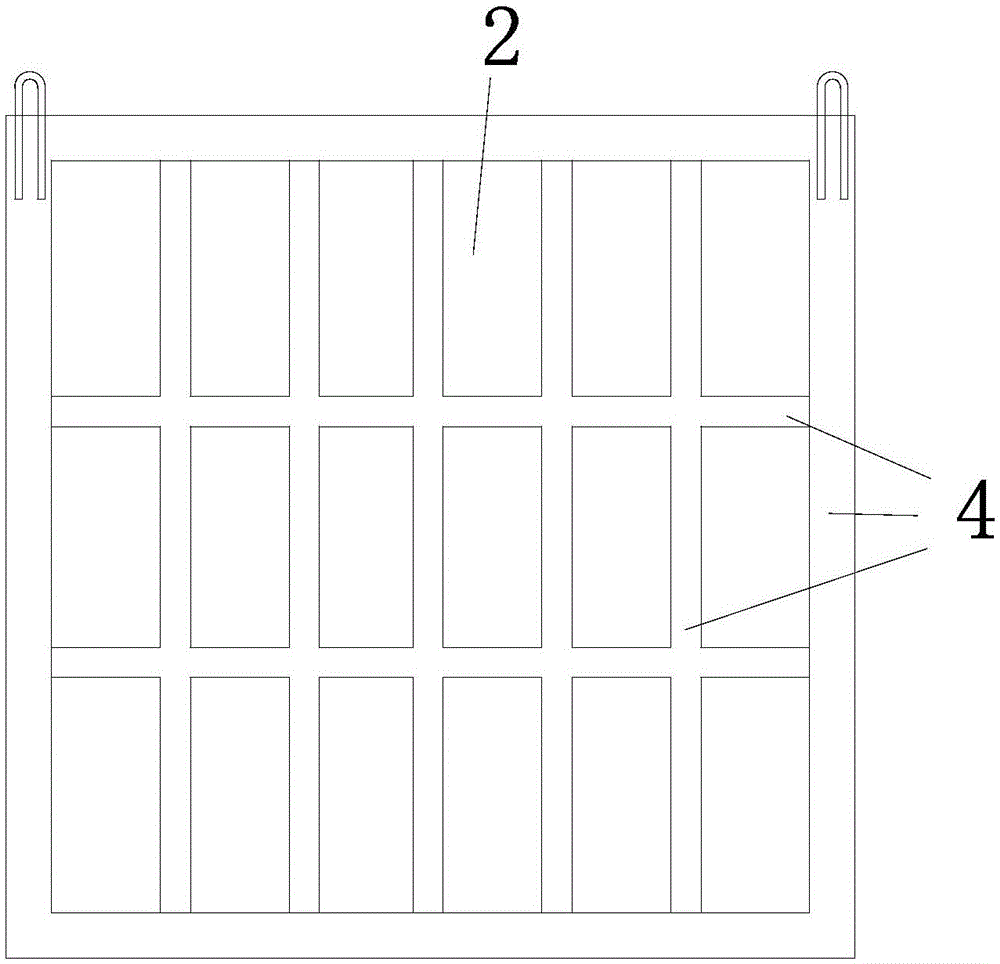

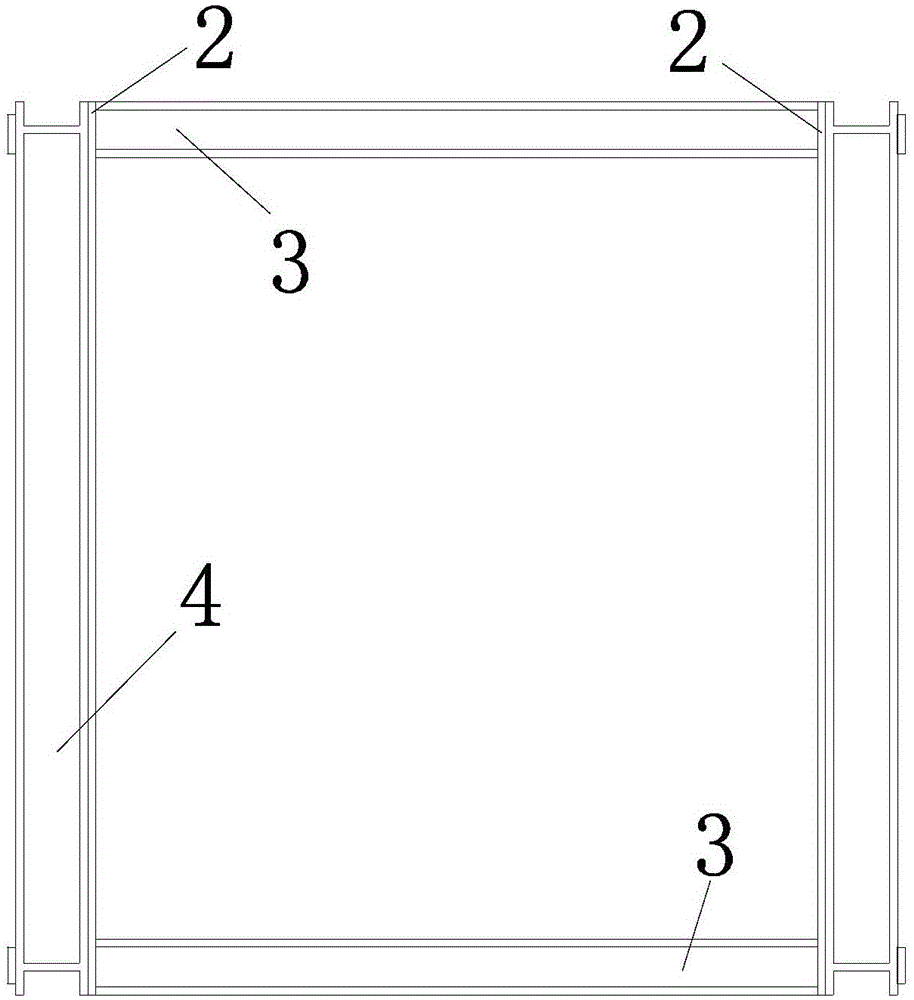

[0043] refer to Figure 1-Figure 3 As shown, the model box 1 includes a U-shaped support frame 4, and tempered glass 2 is arranged inside the support ends on both sides of the U-shaped support frame 4;

[0044] The top of the support frame 4 is provided with two I-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com